USER'S MANUAL UNIVERSAL CENTRIFUGE CENTRIC 150

Page 1

TABLE OF CONTENTS

TABLE OF CONTENTS...................................................................................................................1

1.0 IMPORTANT GENERAL INFORMATION............................................................................2

2.0 GENERAL INFORMATION .....................................................................................................2

2.1 DEFINITION ............................................................................................................................2

2.2 TECHNICAL DESCRIPTION................................................................................................2

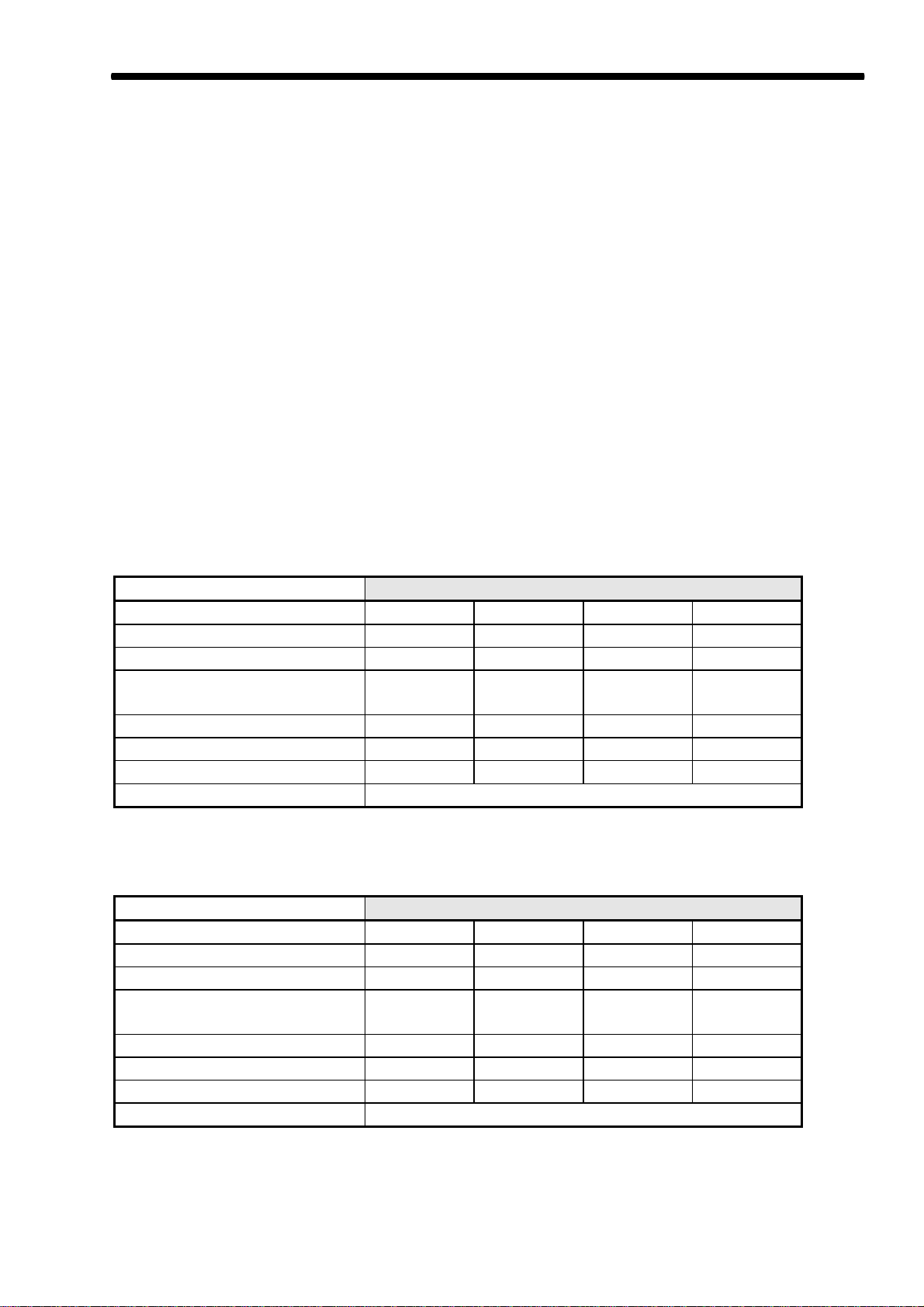

2.3 TECHNICAL DATA................................................................................................................3

2.4 SECURITY FUNCTIONS .......................................................................................................4

3.0 INSTALLATION.........................................................................................................................4

3.1 CENTRIFUGE PLACING.......................................................................................................4

3.2 ATTACHING THE POWER CORD......................................................................................4

3.3 PRIMARY EQUIPMENT........................................................................................................4

3.4 COVER OPENING ..................................................................................................................4

3.5 MANUAL OPENING THE COVER......................................................................................5

4.0 ROTORS AND ACCESSORIES................................................................................................5

4.1 ROTOR FIXING ......................................................................................................................5

4.2 ROTOR REMOVING..............................................................................................................5

4.3 ROTOR LOADING..................................................................................................................6

4.4 CRITICAL SPEED...................................................................................................................6

4.5 CALCULATING MAXIMUM ROTOR SPEED...................................................................7

4.6 ROTORS AND ACCESSORIES.............................................................................................7

5.0 CENTRIFUGING ........................................................................................................................8

5.1 CENTRIFUGE CONTROL.....................................................................................................8

5.2 SECURITY FUNCTIONS AND ERROR DETECTION .....................................................9

5.2.1 ROTOR BRAKING AT SWITCH ON TIME .....................................................................9

5.2.2 COVER BLOCKING...........................................................................................................9

5.2.3 ROTOR IMBALANCE........................................................................................................9

5.2.4 ROTOR IDENTIFICATION................................................................................................9

5.2.5 MOTOR FAILURE..............................................................................................................9

5.3 ERRORS....................................................................................................................................9

5.4 USER INTERFACE ...............................................................................................................10

5.4.1 LC DISPLAY .....................................................................................................................10

5.4.2 LIGHT INDICATORS.......................................................................................................10

5.4.3 KEYBOARD......................................................................................................................11

5.5 SETTING AND CHANGING PARAMETERS...................................................................11

5.6 ACTIVATION-DEACTIVATION CENTRIFUGING.......................................................12

5.7 OPERATING ..........................................................................................................................12

6.0 INCORRECT USAGE...............................................................................................................13

7.0 POWER INTERRUPTS............................................................................................................13

8.0 MAINTENANCE.......................................................................................................................13

8.1 CLEANING INSTRUCTIONS..............................................................................................14

8.2 DECONTAMINATION .........................................................................................................14

9.0 WARRANTY..............................................................................................................................14

10.0 TRANSPORT...........................................................................................................................14

11.0 CENTRIFUGAL ACCELERATION RCF FOR DIFFERENT ROTORS........................15