2

All eld wiring modications should be made in compliance

with the latest edition of IEC 60335-1 and 60335-2, and

any applicable country and local codes.

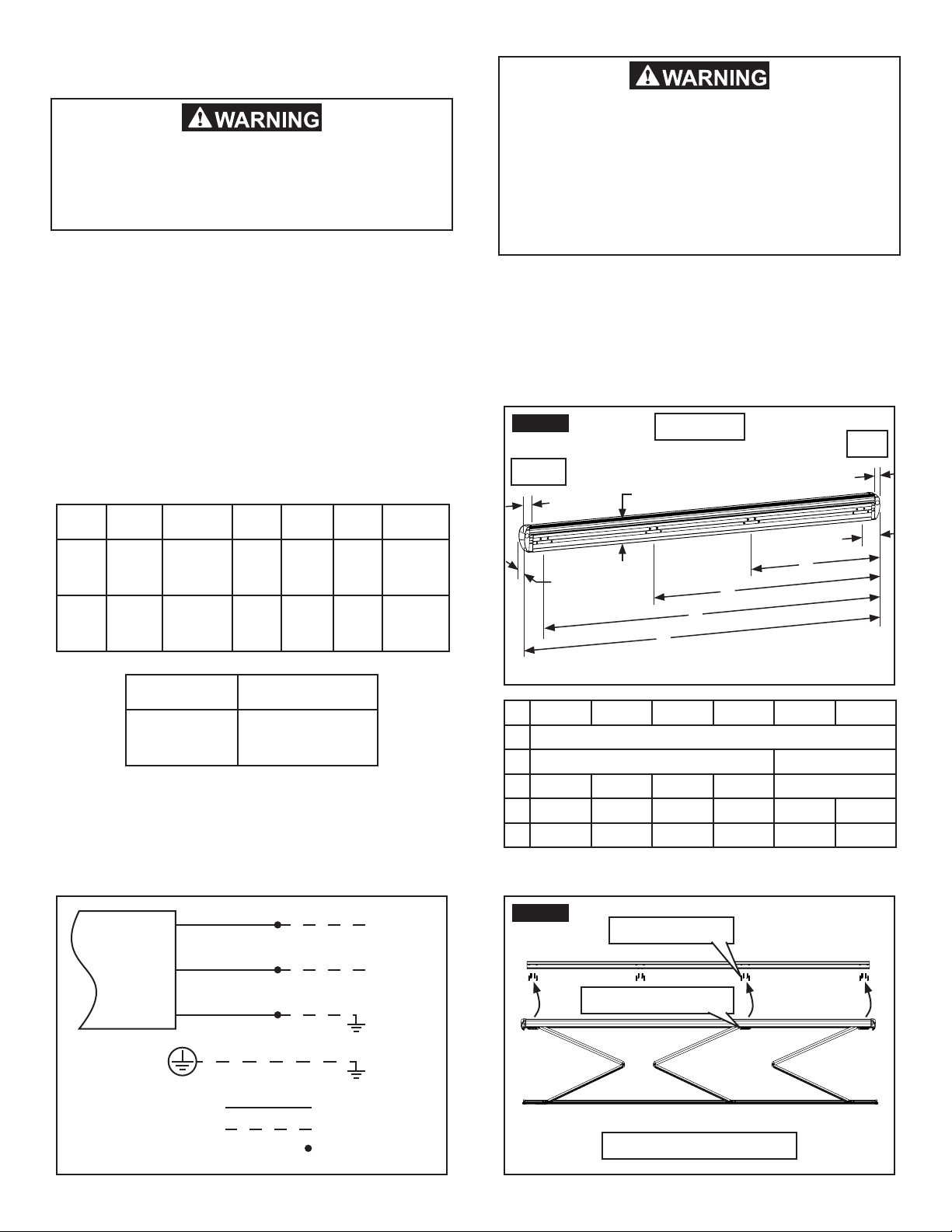

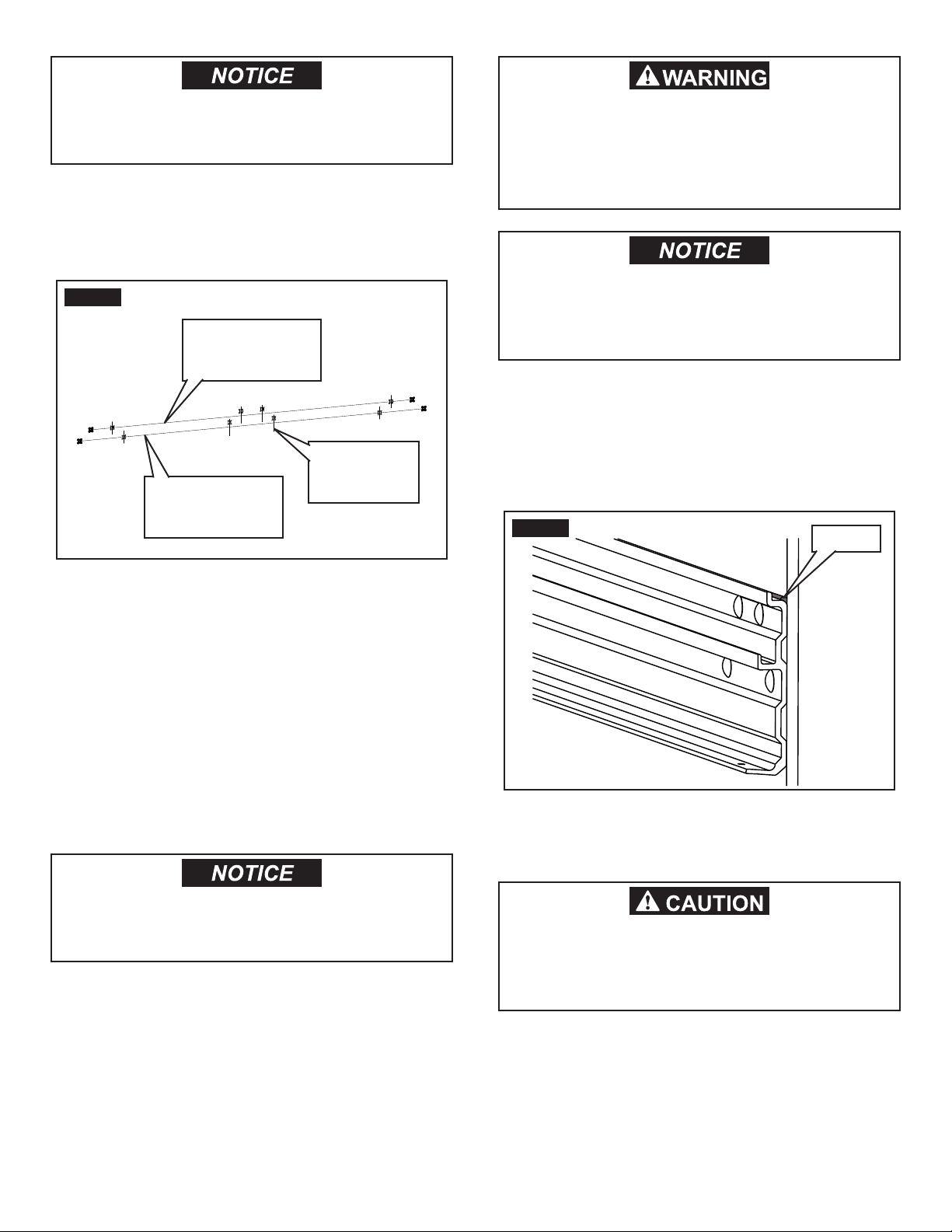

Required hardware:

2.5 M - 4 M Models Only:

(1) Mounting Bracket

(3) Backing Plate

(12) 10.3 mm O.D. Sleeves

(12) M6 X 50 mm L Carriage Bolt

(12) M6 Split Lock Washer

(12) M6 Flat Washer

(12) M6 Locknut With Nylon Insert

(6) 8-18 X .38 Self Drilling Flat Head Screw

Additional hardware quantities:

4.7 M - 5 M Models only:

(1) Backing Plate

(4) 10.3 mm O.D. Sleeves

(4) M6 X 50 mm L Carriage Bolt

(4) M6 Split Lock Washer

(4) M6 Flat Washer

(4) M6 Locknut With Nylon Insert

(2) 8-18 X .38 Self Drilling Flat Head Screw

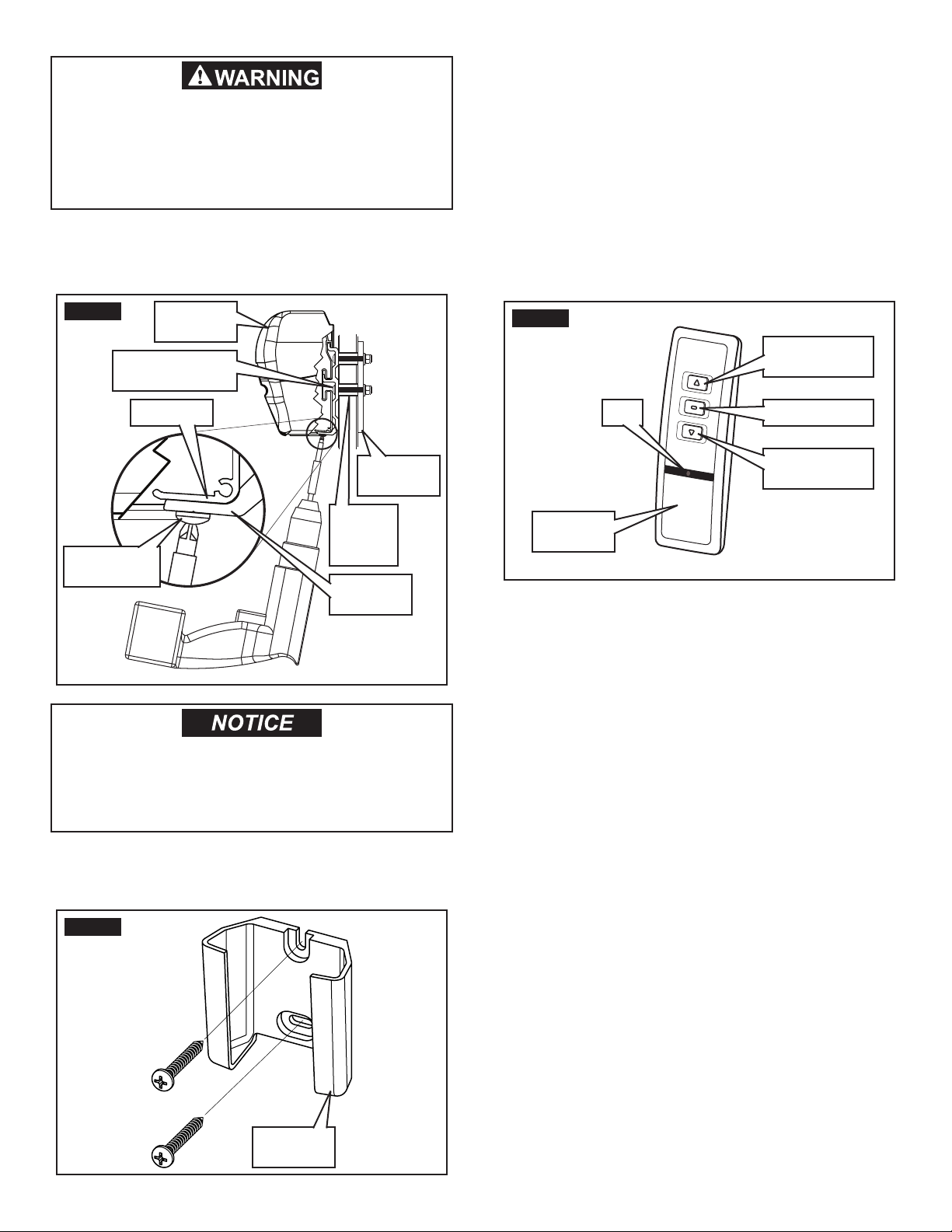

Required tools:

3 mm Hex Key

6 mm Hex Key

10 mm Socket (and wrench)

Torque Wrench (with 6 mm Hex Key Socket)

PH Phillips Head Screwdriver (or bit and drill)

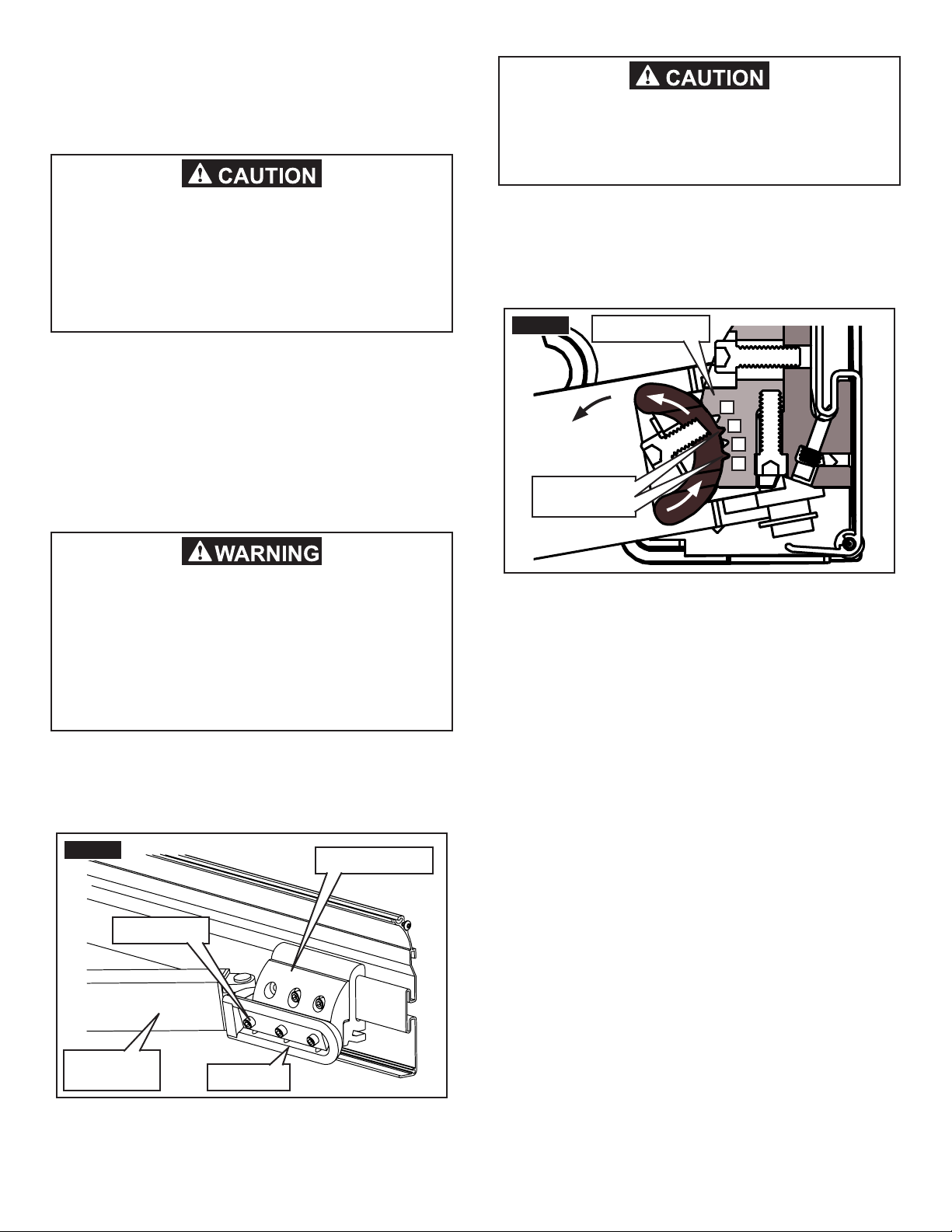

Optional accessories:

3313888.000 Kit, Solar Sensor

3313943.000 Kit, Remote Wall Control

3313981.000 Kit, Remote (additional)

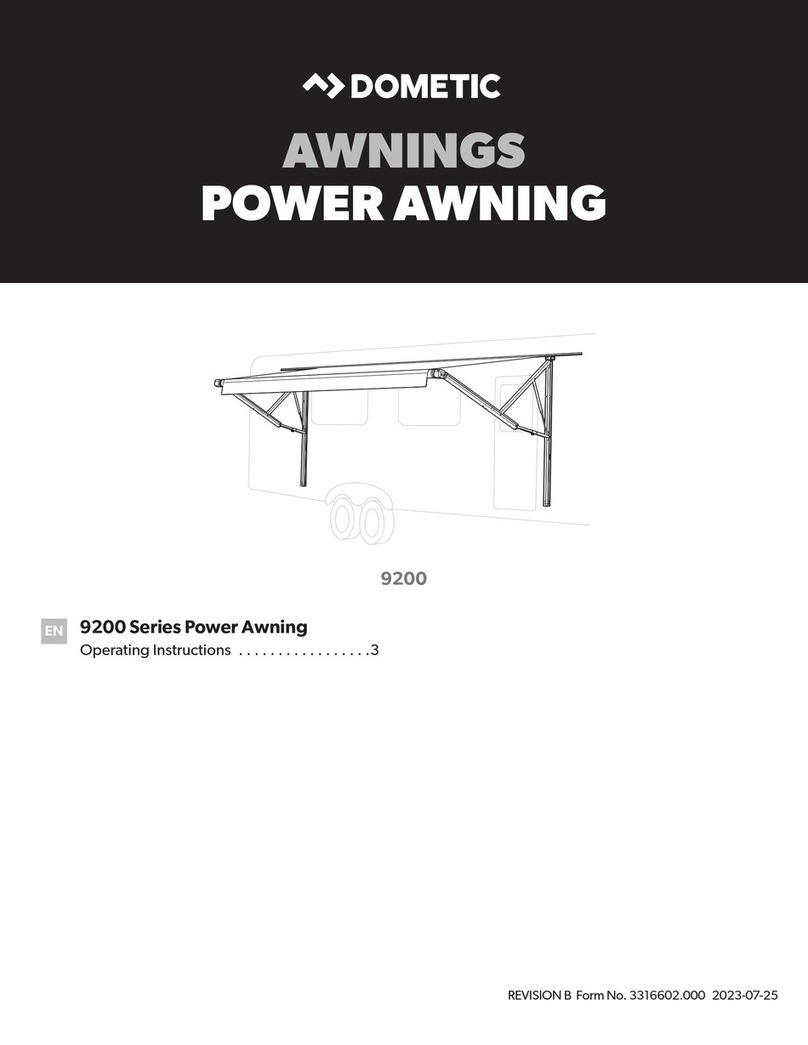

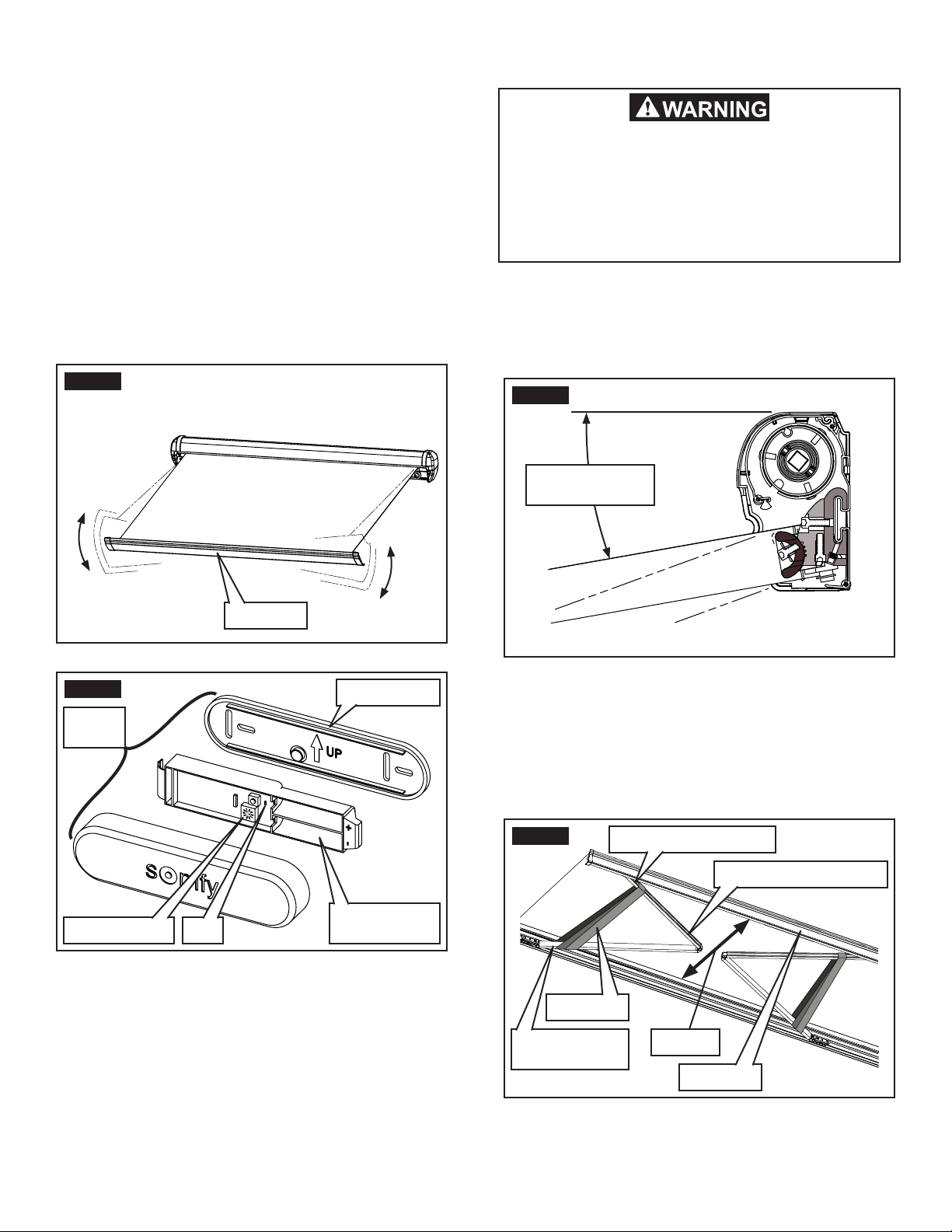

A. Application

The cassette awning is ideal for use on RVs. It is especially

well suited for RVs with an over cab extension where there

is not sufcient surface for a bottom mounting bracket.

Cassette awnings can be installed by one person with

brief help from additional personnel. Use the following

procedure to ensure a properly installed, and properly

functioning awning.

Dometic, LLC reserves the right to modify appearances

and specications without notice.

IMPORTANT SAFETY INSTRUCTIONS

This manual has safety information and instruc-

tions to help users eliminate or reduce the risk

of accidents and injuries.

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. It is used to alert

you to personal injury hazards. Obey all safety

messages that follow this symbol to avoid pos-

sible injury or death.

UNDERSTAND SIGNAL WORDS

A signal word, when used with the safety alert

symbol, will identify a safety hazard and its level

of risk for personal injury. A signal word, without

the safety alert symbol, will be used for property

damage messages only.

WARNING indicates a hazard-

ous situation which, if not avoided, could result

in death or serious injury.

CAUTION, used with the safe-

ty alert symbol, indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE is used to address

practices not related to personal injury.

GENERAL INSTRUCTIONS

These instructions must be read and under-

stood before installation of this hardware.

This hardware must be installed by a Dometic,

LLC Service Center or a qualied service tech-

nician. Incorrect installation can lead to se-

vere injury. Follow all installation instructions.

Modication of this product can be extremely

hazardous and could result in personal injury

or property damage.

Read and follow all safety instructions for

installation to avoid possible injury or death.