6

STEP 3. PREPARING THE COOLING UNIT

FOR THE ICE MAKER (Models with

ice makers)

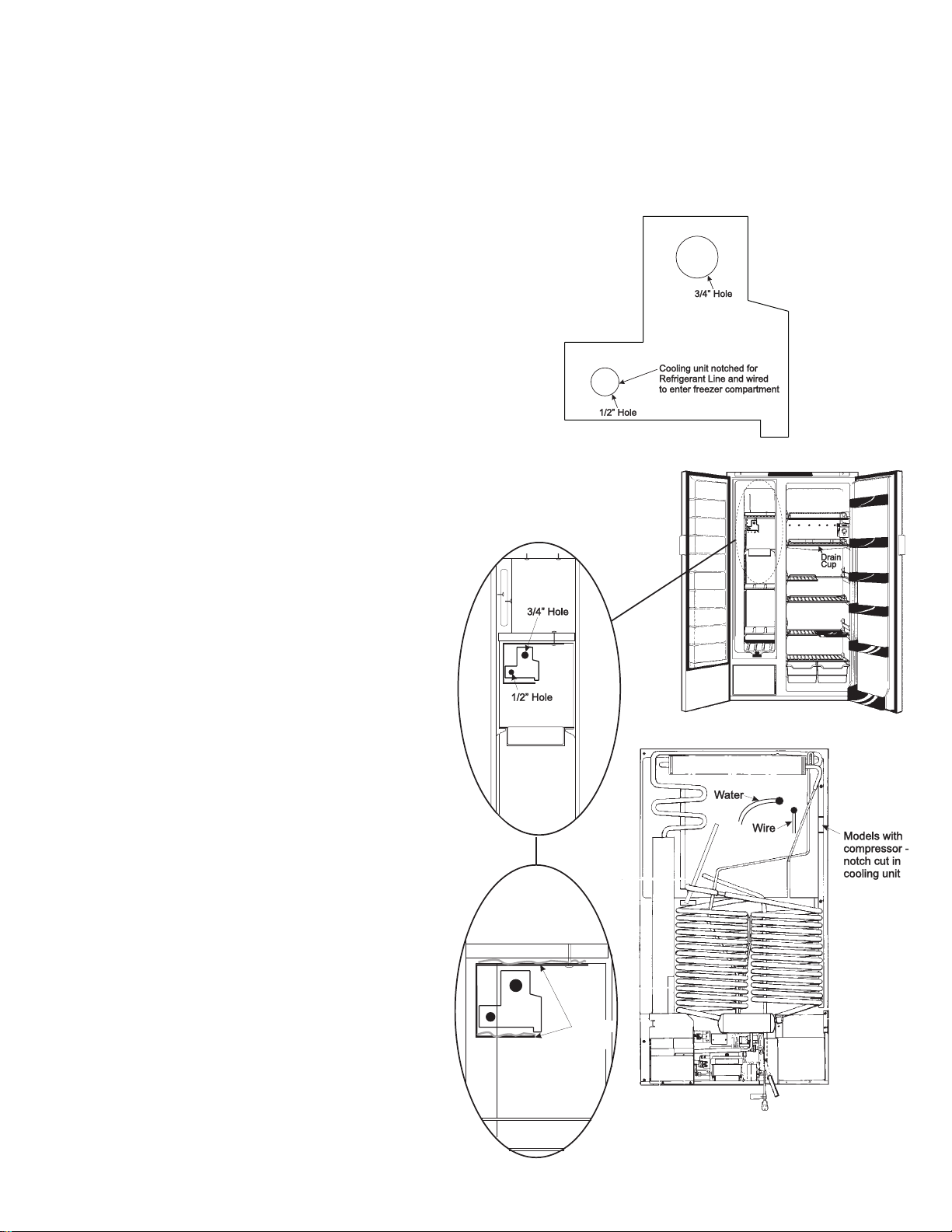

1. Modelswithcompressorassisticemaking,requirea

groovetobecutinthefoamblocktoallowapathforthe

refrigerantlineandwireharness. Thisgrooveneedsto

bepresentbeforethe cooling unit can be fitted intothe

cabinet. Models without the compressor should pro-

ceed to number 6.

2. Thecoolingunitframeismanufacturedwithanotchcut

intoit. Thisnotchiswheretherefrigerantlineandwire

harness will pass through once the foam block is cut

away. Useahacksawandmakethegrooveontheright

handsideofthefoamblock. Thegrooveshouldbethe

same dimensions as the notch in the frame. See FIG.

C5 & C7.

3. The cooling unit can be installed into the refrigerator.

See Section A, Category #1, Step 2, 1-5.

4. Beforetheshelvesandotherinteriorpartsareplacedinto

thecabinet,theopeningfortheicemakerwaterlinemust

bemadethroughthefoamblockofthecoolingunit. Look

at the defective cooling unit to determine the approxi-

mate location and angel to drill the hole in the new

cooling unit. The hole is drilled from the interior of the

cabinetoutthroughtherearoftherefrigerator. Usea3/

4” by 8” long drill bit to make the hole. Be careful no to

drillintoanyrefrigerant lines,causingaleak. SeeFIG.

C6.

5. Proceedto number8.

6. Models without compressor, the cooling unit can be

installed into the refrigerator. Before the shelves and

other interior parts are placed into the cabinet, the

openingfor the ice maker water lines andpower cords

mustbemadethroughthefoamblockofthecoolingunit.

Look at the defective cooling unit to determine the

approximatelocationandangeltodrilltheholeinthenew

coolingunit. Thetwoholesaredrilledfromtheinteriorof

thecabinetoutthroughtherearoftherefrigerator. Use

a1/2”and3/4”by8”longdrillbittomakethetwoholes.

Becarefulnottodrillintoantrefrigerantlines,causinga

leak. See FIG. C6.

7. Thewireharnessisroutedfromtheinsideofthefreezer

compartment through the 1/2” hole. Pull the wire

harness through the back wall of the freezer compart-

ment. Leave sufficient length of wires (about 8”) to

connect to the cycle. Follow the same path that was

usedbeforebythewireharnessandreconnectittothe

solenoidandpowercord.

8. Routethewaterlinefromthewatersolenoiduptherear

oftherefrigerator. Insertthefilltubefromtherearthrough

the3/4” hole. Use permagumto make an air tight seal

aroundthewireharnessandwaterfilltube. Sealboththe

outsideandinside. Ifthewaterlineisnotattachedtothe

filltubeitshouldbeconnectednow. Makesurethatthe

sameroutingisfollowedbetweenthewatersolenoidand

fill tube. If the water line has heat tape, be sure it is in

place. Usealuminumfoiltapetocoverandsealthewater

line and wire harness to the back of the cabinet. See

FIG.C7.

9. Spread a thin layer of thermomastic on top of the ice

makershelf. SeeFIG.C8.Plug thewireharnessto the

ice cycle. Install the cycle using the screws removed.

Makesure the end of thewater fill tube will allowwater

to enter the cycle inlet, and is free from touching the

sides or bottom. This will allow the water to drain

completelyout ofthefilltube andpreventfreezing.

10. Return to Section C, Category #3, Step 2, #3.

FIG. C5

FIG. C6

FIG. C7

FIG. C8

APPLY

THERMO

MASTIC

TO TOP