Installation

Optional added features

The DP100 can be configured to suit customer specification.

These optional extras would be discussed, arranged and

installed prior to delivery.

(If unsure what features your DP100 is equipped with

please contact the seller with the unit serial number,

(Refer to section 2for location) who will be able to advise

what specification has been supplied.

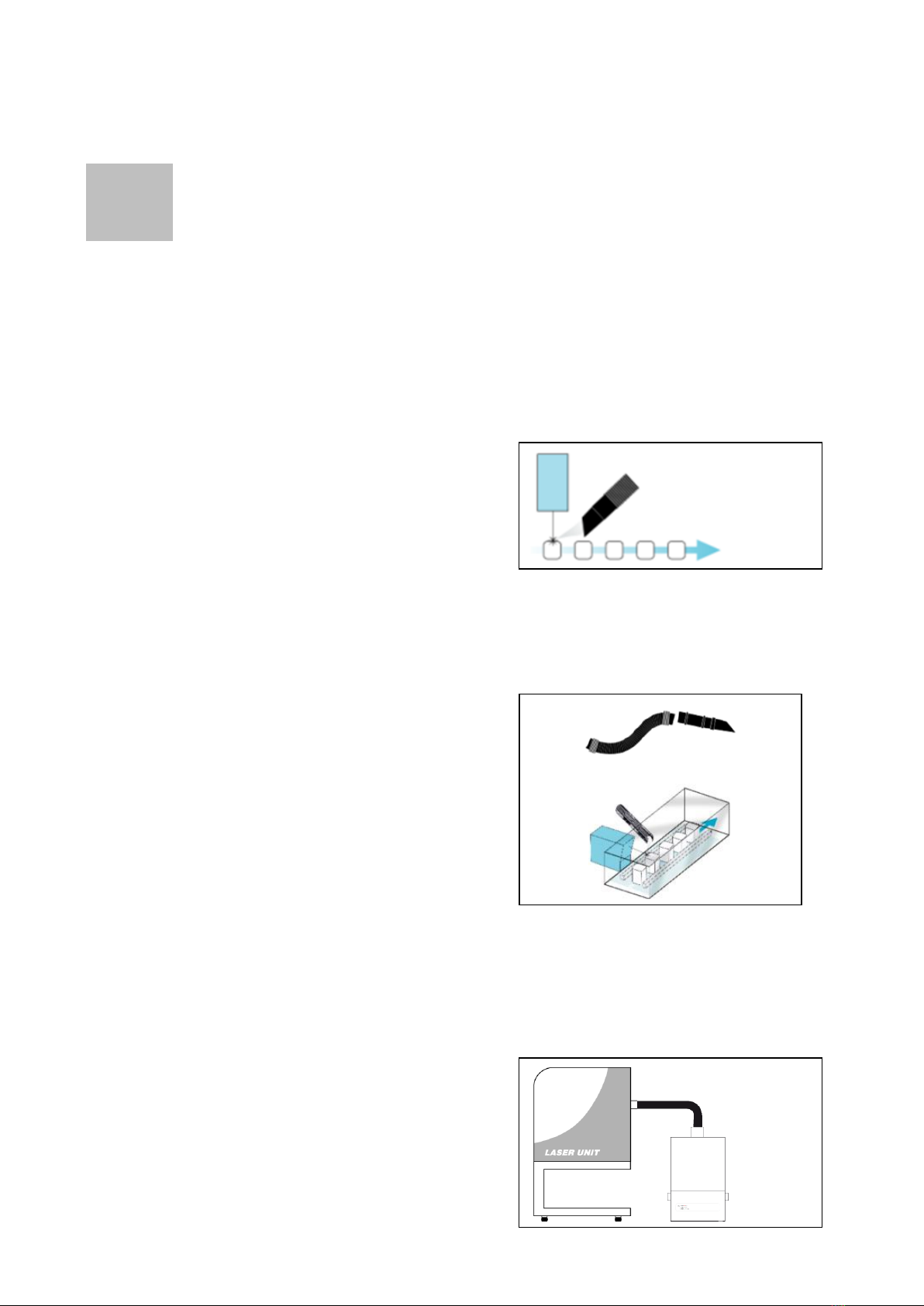

Filter blocked/System failure signal.

With this option the extraction unit will have been fitted

with a pressure transducer to monitor the condition of the

filters and to indicate the extractor is running, this signal is

available via the green and white cores of the control cable

that exits the cabinet next to the power cable or via the D-

type connector. The signal is a “volt free” contact, i.e. a

closed circuit will exist between the green and white wires

when the filter condition is good and the unit is running. This

will change to an open circuit on filter blockage or system

failure. This feature should only be used on control voltage

circuits. The signal can be connected to the laser or

alternatively to operate a beacon, siren or warning device.

Open circuit condition of this circuit will not directly stop the

extractor motor.

Remote Stop/Start feature

Enables the extraction unit to be remotely turned On / Off

via an external signal.

This feature can be configured in 3 ways

•DC Voltage input –Range 12-24VDC

•Volt free input –Open / Closed contacts

•Override –Stop / Start feature switched off

Note: Care must be taken to ensure that the system is correctly

wired in order for the extraction unit to function correctly.

DC Voltage input

This configuration requires the Black & Red cores of the

signal cable (Refer to section 1 for location) to be connected

to a known and tested DC power supply, in order to start the

extractor.

The operating voltage for this signal is between 12 &

24VDC. Only voltages within this range should be

connected. Voltages connected outside of this range may

cause irreversible damage to the internal control PCB.

Red cable = V+

Black cable = V-

When the extractor is provided with the correct DC voltage

the motor will start and maintain the set flow rate (Refer to

section 5for how to set the flow) when the DC voltage is

removed the motor will slow down and come to a stop.

The extractor will need to be turned on (See section 5 for

turning the extractor on) in order for this feature to operate.

Volt free input

This configuration requires the Black & Red cores of the

signal cable (see section 1 for location) to be connected

together, in order to start the extractor.

When the 2 cables are connected together the motor will

start and maintain the set flow rate (see section 5for how to

set the flow)

when the 2 cables are disconnected the motor will slow

down and come to a stop.

The extractor will need to be turned on (See section 5 for

turning the extractor on) in order for this feature to operate.

Override

Enables the extractor to operate fully with or without either

DC voltage input or the Volt free input.

The override feature can be toggled On / Off by a switch

mounted on the internal motor access panel (see below for

switch location)

Switch in “On” position

In this position the extractor will require a start signal (either

Voltage input or Volt free, depending on the requested

specification) to enable the motor within the extraction unit.

Switch in “Off” position

In this position the extractor motor will run without the

requirement for an external start signal. This feature is

useful for engineers carrying out works/ tests on the

extractor without the need for the auxiliary signal being

present.