- Page 2 of 60 -

Report No. STS200421001001E

Shenzhen NTEK Testing Technology Co., Ltd

TEST REPORT

IEC/EN 62368-1

Audio/video, information and communication technology equipment

Part 1: Safety requirements

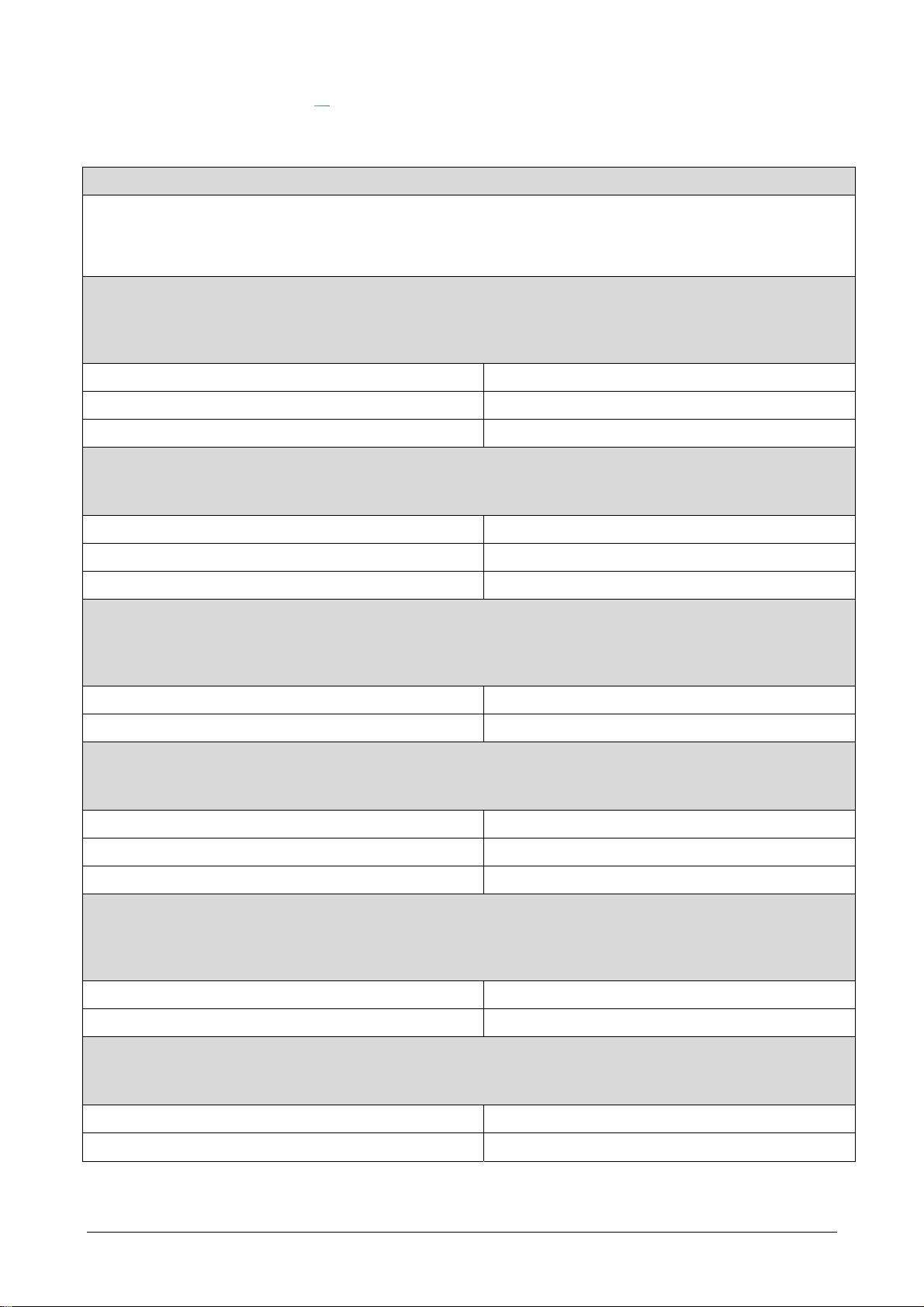

Report Number .............................. : STS200421001001E

Tested by (name + signature) ...........: Keny Fu

Approved by (name + signature) ......: Helen Lin

Date of issue ................................... : 2020-06-15

Testing Laboratory ............................. Shenzhen NTEK Testing Technology Co., Ltd.

Address .............................................. 1/F, Building E, Fenda Science Park, Sanwei Community, Xixiang

Street, Bao’an District, Shenzhen 518126 P.R. China

Applicant’s name ............................ : Shenzhen DOOGEE Hengtong Technology CO., LTD

Address ........................................... : B, 2/F, Building A4, Silicon Valley Power Digital Industrial Park, No.

22, Dafu Industrial Zone, GuanlanAobei Community, GuanlanStreet,

Longhua New District, Shenzhen

Test specification:

Standard ........................................ : IEC 62368-1:2014 (Second Edition)

EN 62368-1:2014+A11:2017

Test procedure ............................... : CE Scheme

Non-standard test method ............. : N/A

Test Report Form No. .................. : IEC62368_1B

Test Report Form(s) Originator ..... : UL(US)

Master TRF .................................... : 2014-03

Copyright © 2014 Worldwide System for Conformity Testing and Certification of Electrotechnical

Equipment and Components (IECEE), Geneva, Switzerland. All rights reserved.

Test Item description ........................ Smart Phone

Trade Mark ....................................... DOOGEE

Manufacturer ...................................... Shenzhen DOOGEE Hengtong Technology CO., LTD

Manufacturer address ........................ B, 2/F, Building A4, Silicon Valley Power Digital Industrial Park, No.

22, Dafu Industrial Zone, GuanlanAobei Community, GuanlanStreet,

Longhua New District, Shenzhen

Model/Type reference ....................... S88Pro, S88

Ratings .............................................. Input: 12VDC, 2000mA