4

SAFETY INSTRUCTIONS

WARNING! RISK OF INJURY!

Have a qualified technician lay the cables 220–240 V AC. The cables must be laid in protective corrugated tubes. Avoid

contact of cables and moving parts of the door. In case of supply cable damage, use the suitable type of the cable.

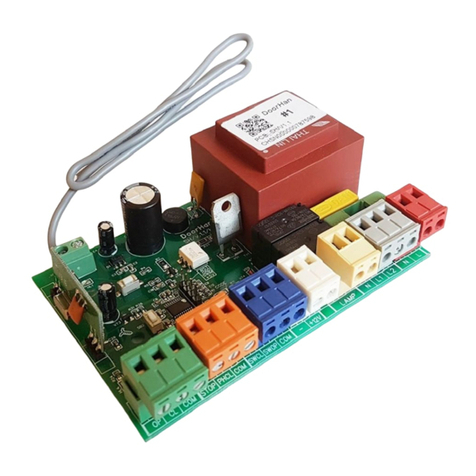

Cable needed for installation of Shaft-30 and accessories (if available).

• Cable 2 × 0.5 mm2 (photocell transmitter, stepped control button).

• Cabel 4 × 0.5 mm2 (photocell receiver).

• Cable 3 × 1.5 mm2 (power supply).

• The cables should be appropriately insulated.

When performing operation at height, use a stable support.

When drilling holes, use protection for hands and eyes.

For fastening of the item, use hardware supplied with the operator or other analogous one.

Disconnect the supply when cleaning or other maintenance is being carried out, if the appliance is automatically controlled.

If the operator is installed on the door with a wicket door an additional safety device should be used to prevent operator

activation when the wicket door is open.

Ensure that entrapment between the driven part and the surrounding fixed parts due to the opening movement of the

driven part is avoided.

It is highly recommended to use DoorHan optional equipment as the accessories produced by other manufacturers can

damage the automated system.

DoorHan is not responsible for unstable work of the automatic system when using safety devices and accessories, which

are produced by other manufactures without agreement with DoorHan.

Never leave the electric motors in released condition. This may cause uncontrolled movement of the door leaves and,

consequently, their breakdown.

Do not use the operator if it needs repair or adjustment as installation defects or unbalanced door can cause injury.

DoorHan shall not be held liable in case of improper installation of the item and damage arisen during operation.

Since the operator does not have a power cord with a plug it shall be connected to the mains supply via automatic switch

with a minimal distance of 3 mm between the neighboring contacts. It is recommended to use a 10А double -ole circuit-

breaker.

Be sure there are no obstructions to door travel.

Do not make any changes in the automatic system not specified in this manual.

Remove package of the item and dispose of it. Keep the package materials away from children.

Always keep remote controls out of reach of children. Never permit children to operate or play with garage door control

push buttons or remote controls.

No one should cross the pass of the moving door.

The content of the manual shall not be basis for any claim.

The manufacturer reserves the right to modify the design of the product described in this manual without preliminary

notice.

WARNING! For safe and correct operation of the operator put a stopper to limit door travel.

The Installation and configuration of the actuator must only be carried out by qualified specialists.

After installing the drive, test force according to standards EN 12445 and EN 12453.