8

NHM/NHP Series NHM/NHPATCE29

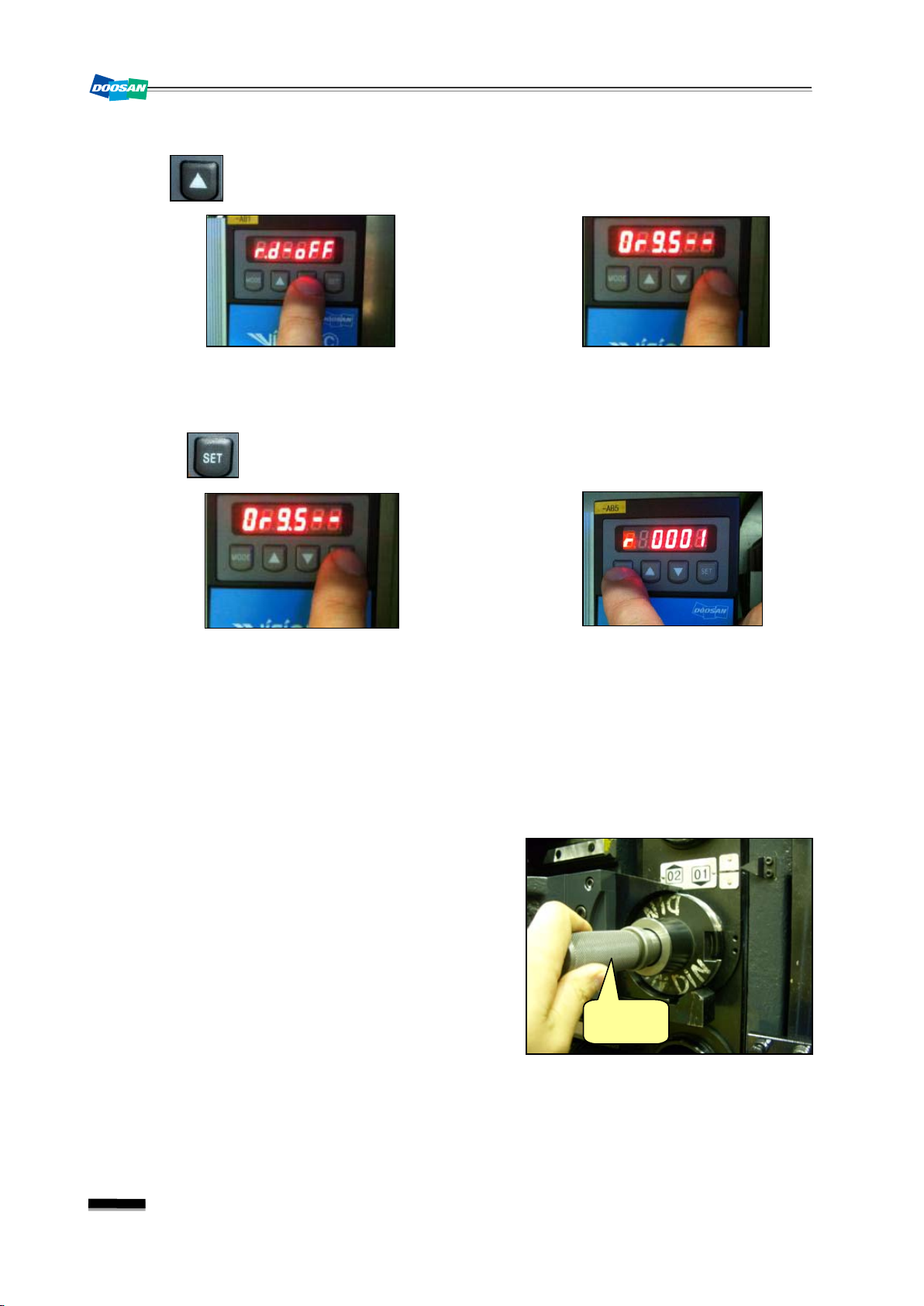

②

Adjust the left/right position of the tool carrier pot

Use the center bar to check the centering position between tool carrier pot and sub

changer. If they are misaligned, use the side stopper of the tool carrier (see the figure

below) to make fine adjustment.

※

If the center bar is not inserted smoothly after adjusting the left/right stopper, refer to

"Adjust the vertical position of the tool carrier pot"

below. If you had adjusted the

stroke of the hydraulic cylinder of the sub changer, this might have happened because the

chain pot was misaligned. You should check out the chain pot first.

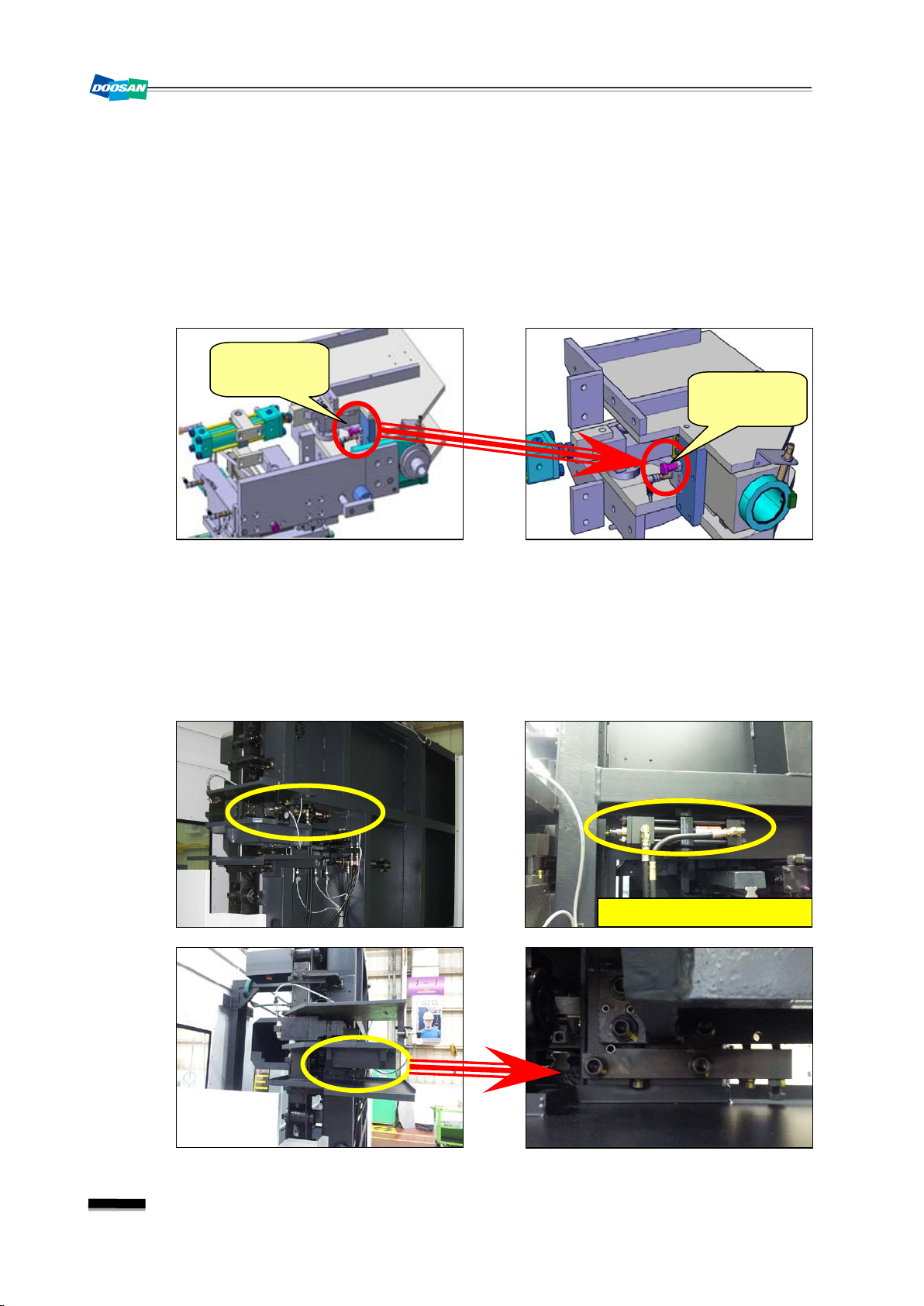

③

Adjust the vertical position of the tool carrier pot

(↕)

Use the center bar to check the centering position between tool carrier pot and sub

changer. If they mismatch, loosen the bolts (fixing the cylinder to the tool carrier pot

assembly) and use the vertical adjustment bolts to make correction.

※

However, you seldom need to make vertical adjustment as the tool carrier pot assembly is

tightened up using the pins.

Horizontal

adjustment

stopper

Horizontal

adjustment

stopper

Loosen the cylinder bolts