Vehicle System Index3

Index

Specification..................................5

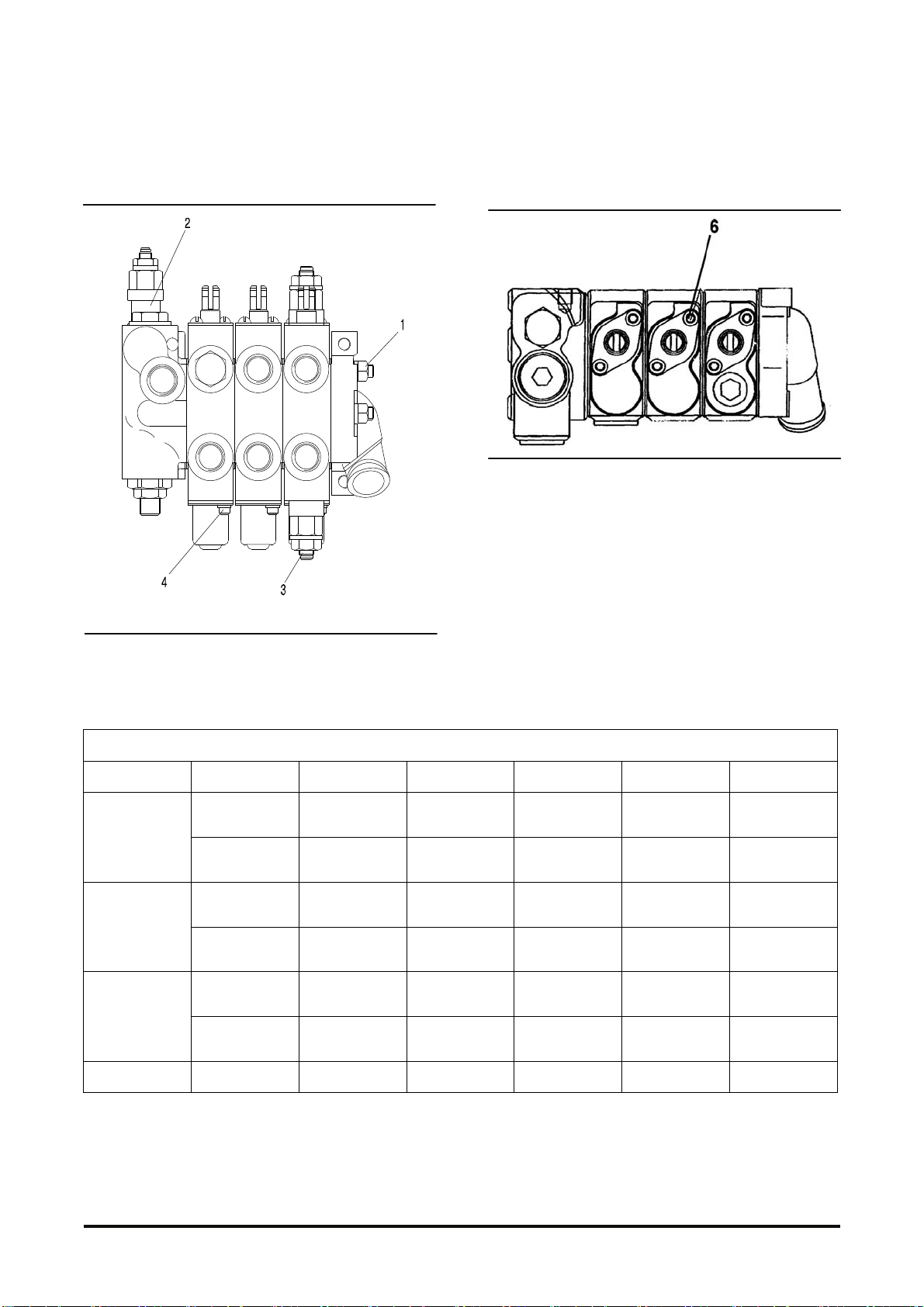

Hydraulic Control Valve.........................................5

Hydraulic Pump ....................................................6

Lift Cylinder...........................................................6

Standard........................................................6

Full Free Triple and Full Free Lift....................7

Tilt Cylinder...........................................................8

Mast .....................................................................9

Carriage................................................................9

Lift Relay Group - Full Free Lift ...........................11

Lift Relay Group - Full Free Triple Lift..................12

Lift & Tilt Mounting Group....................................13

Steering Wheel...................................................14

Steering Gear.....................................................15

Steer Axle and Wheel .........................................16

Steer Wheel Mounting.........................................17

Shoe Brake.........................................................17

System Operation ....................... 18

Hydraulic System................................................18

Basic Schematic - Standard.........................18

Optional Schematic with hyd. locking system

...20

Hydraulic Control Valve................................22

Steering System.................................................27

Steering Cylinder .........................................27

Steering Gear..............................................28

Brake System.....................................................30

Master Cylinder............................................30

Shoe Type Brake.........................................31

Automatic Adjustment..................................31

Parking Brake..............................................31

Testing and Adjusting................ 32

Troubleshooting ..................................................32

Visual Checks ..............................................32

Performance Tests.......................................32

Hydraulic Oil Temperature (Too Hot)............32

Hydraulic System and Mast..........................33

Hydraulic Pump............................................36

Hydraulic Control Valve................................37

Steering System...........................................38

Brake System...............................................39

Parking Brake...............................................40

Hydraulic System................................................41

Relief Valve Pressure Check........................41

Lift Cylinder Air Removal (Only FFT & FFL

Mast)............................................................43

Delayed Engine Shutdown System......................44

Operation.....................................................44

Diagram of Delayed Engine Shutdown System

....................................................................45

Trouble shooting of Delayed Engine Shutdown

System.........................................................46

Diagnostic Fault Codes ................................46

Delayed Engine Shutdown System Schematic

....................................................................47

Delayed Engine Shutdown System Schematic

....................................................................47

Delayed Engine Shutdown System Schematic

....................................................................48

OSS (Operator Sensing System).........................49

Operation.....................................................49

Symbols of OSS...........................................49

Operator Sensing System Schematic ...........50

Trouble shooting of Operator Sensing System

....................................................................51

Mast and Carriage...............................................53

Mast Adjustment...........................................53

Carriage Adjustment.....................................58

Chain Adjustment.........................................59

Chain Wear Test..........................................60

Carriage and Mast Height Adjustment ..........61

Forks Parallel Check....................................61