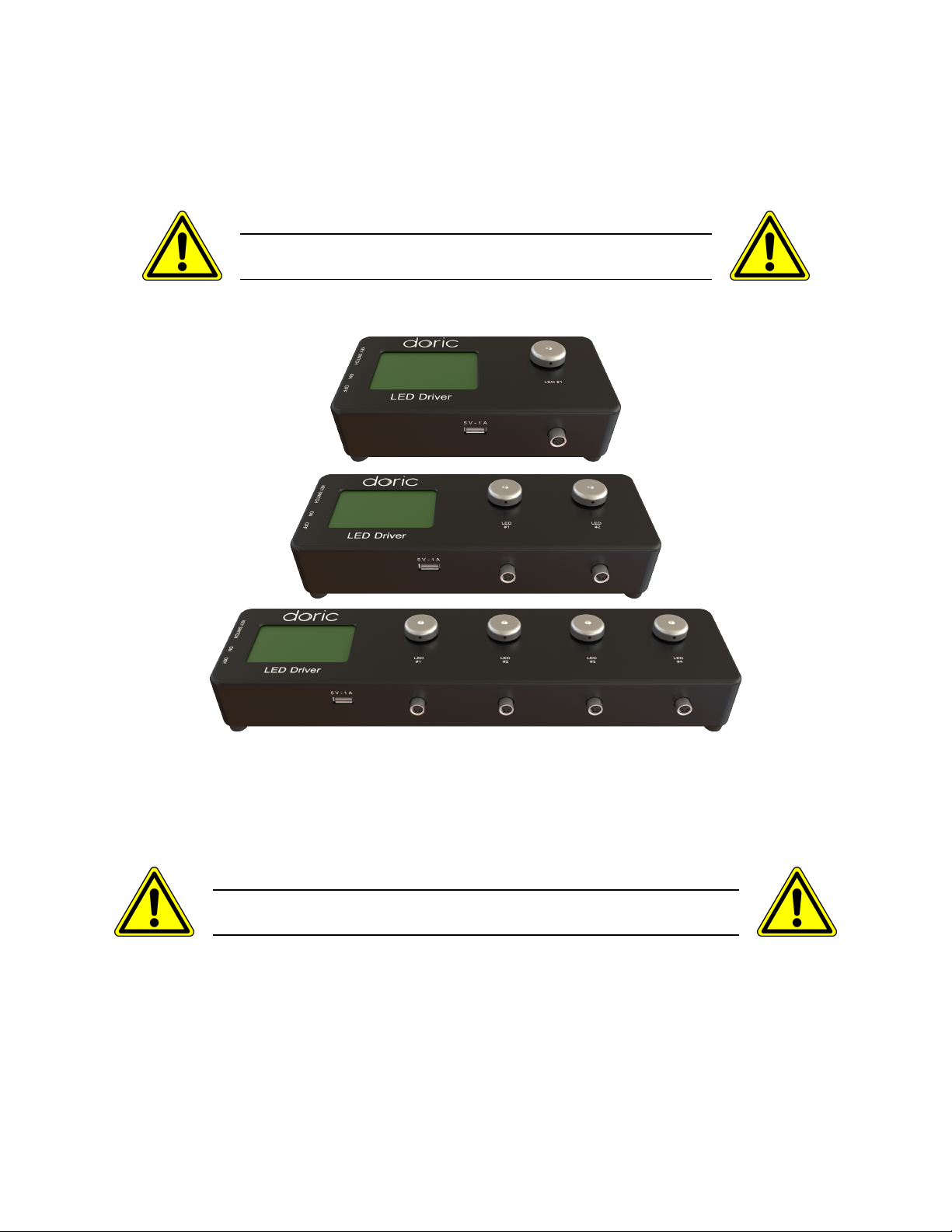

2.5 LED Drivers

The LED driver is used to provide power and control of various LED modules. The Connectorized LED and Connectorized

LED with Fiber-optic Rotary Joint can be used with the 1, 2 or 4-channel LED driver. The Combined LEDs and Combined

LEDs with fiber-optic rotary joints can be used with any driver having at least as many channels as the number of

combined LEDs.

For safety precautions, the LED driver must be powered only by the

power supply provided with the product.

Figure 2.7: LED Drivers; 1-, 2- and 4-channel

Each LED Driver channel can be controlled manually or via the Doric Neuroscience Studio software. During stand-alone

operation, it is possible to change the operating mode (CW, external TTL, or external analog mode) and the current

sent to each LED. These changes can be done directly on the device with the Control Knobs and the LCD Display.

The driver is designed and is tested to be used only with Doric light sources.

For safety precautions, do not connect other devices in the M8 connectors.

Connecting the LED Driver to a computer provides the user with more options. Doric Neuroscience Studio software

allows the access to more operating modes like Continuous Wave, External TTL, External Analog, Square Sequence(s),

and Complex Sequence(s) modes. The Doric Neuroscience Studio enables the creation of different sequences of light

source activation. It also provides the possibility to let these sequences be triggered or paused by an external signal.

If more power is needed, it is possible to overdrive the LED Driver with the software for some LED with overdrive

capability.

•The LCD display (Fig. 2.8) allows easy operation and monitoring. For each channel, the LCD displays the type

of light source (LED), the operating mode, the center wavelength in nm and the current setting.

Chapter 2. Device Overview 10