Table 3.4: General Specifications

SPECIFICATIONS VALUE NOTES

Transmision 80% 200 µm core NA 0.22 Optical fiber

Maximum Variation 2% 200 µm core NA 0.22 Optical fiber

Wavelength Range 450-650 nm Others available on request

Start Up Torque 0.9 mN·m For 6 contacts, Typical Value

1.8 mN·m For 12 contacts, Typical Value

Input NA 0.22 -

Output NA 0.22 -

Fiber Type 200 µm core NA 0.22 -

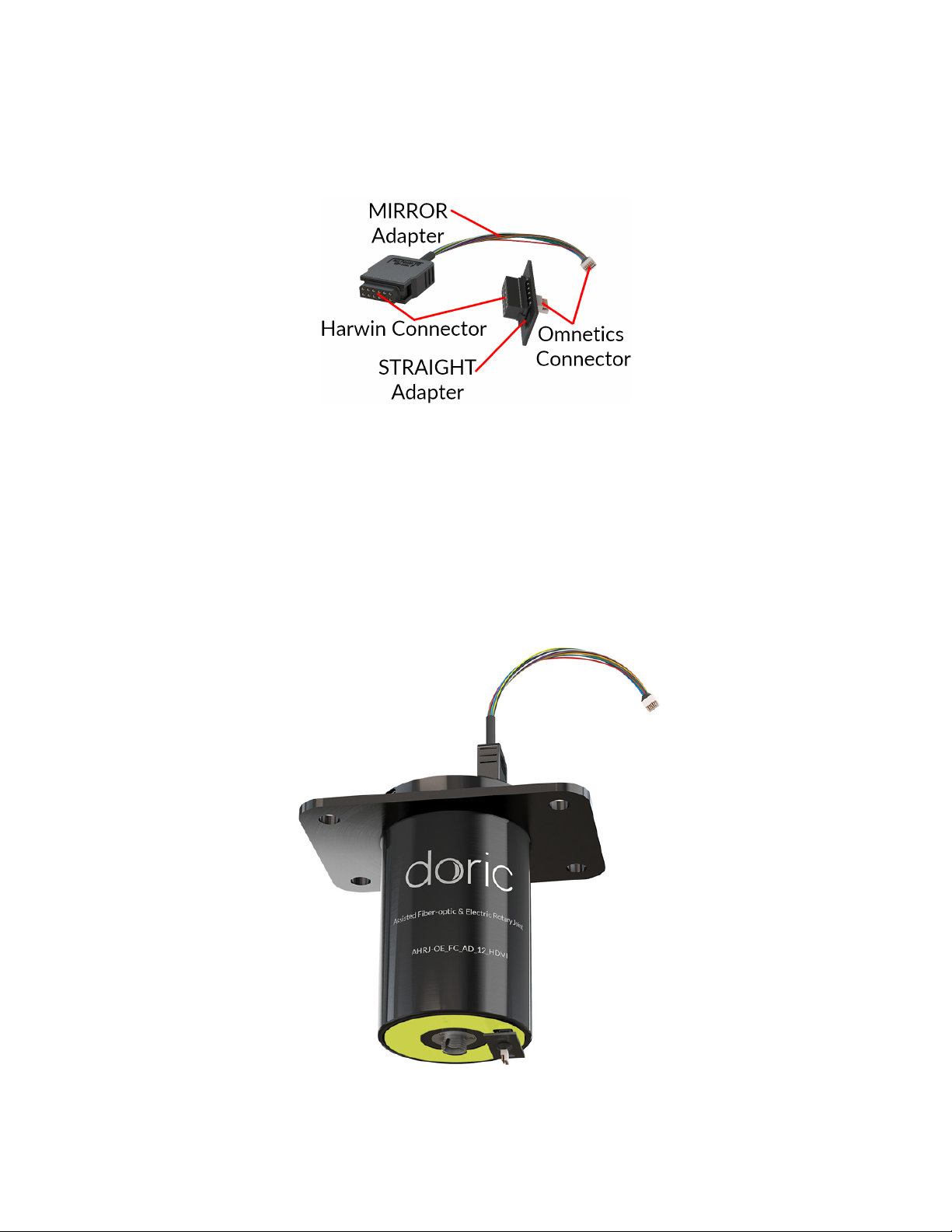

HDMI (Female) connector pinout type Microscope, Blackrock 2 -

Harwin (Male) connector type Datamate L-Tek serie 2 mm pitch, 12 contacts, 2 rows

Number of contacts 12 -

Contact Material Gold -

Maximum Current 2 A per contact -

Contact Resistance <500 mΩ-

Resistance Variation During Rotation (constant rotation) <100 mΩ5 VDC -

Rotation Speed up to 300 rpm -

Outer diameter 45.0 mm -

Length 59.4 mm -

Mass 123 g -

Table 3.5: Recommended Environmental Specifications

DESCRIPTION OPERATION STORAGE

Use Indoor Indoor

Temperature 0-40 ◦C 0-40 ◦C

Humidity 40-60% RH, non condensing 40-60% RH, non condensing

Chapter 3. Specifications 10