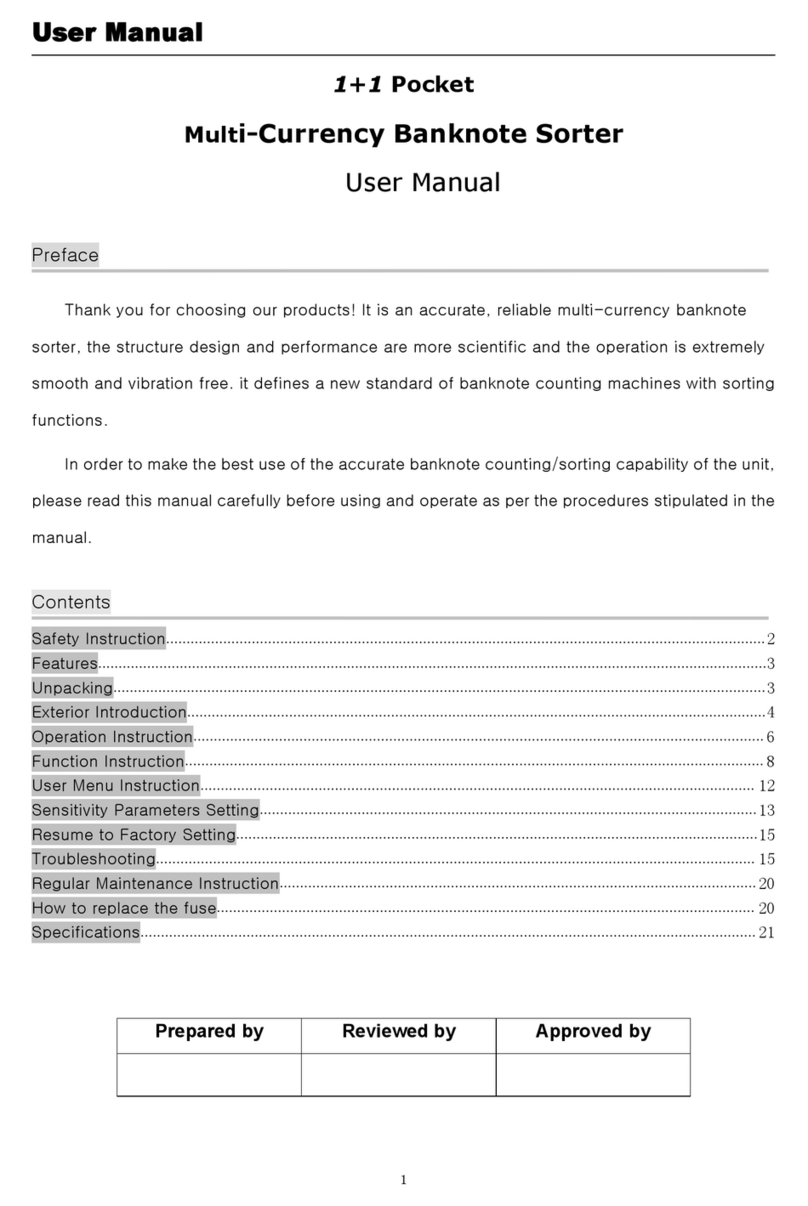

Service maintenance manual

8.26 REMOVAL AND INSTALLATION OF HOOKS............................................................................................128

8.27 REMOVAL AND INSTALLATION OF SEPARATOR COVER ASSEMBLY.......................................................130

8.28 REMOVAL AND INSTALLATION OF SEPARATOR BRACKET ASSEMBLY...................................................133

8.29 REMOVAL AND INSTALLATION OF FEEDING WHEELS SHAFT ASSEMBLY...............................................137

8.30 REMOVAL AND INSTALLATION OF DAMPER SPRINGS............................................................................141

8.31 REMOVAL AND INSTALLATION OF TOP.................................................................................................142

8.32 REMOVAL AND INSTALLATION OF LOWER ENVELOPE ASSEMBLY.........................................................143

8.33 REMOVAL AND INSTALLATION OF STACKER UNIT ASSEMBLY ..............................................................144

8.34 REMOVAL AND INSTALLATION OF OPENING SENSOR MODULE..............................................................147

8.35 REMOVAL AND INSTALLATION OF STACKER SHAFT ASSEMBLY............................................................148

8.36 REMOVAL AND INSTALLATION OF DRIVE ROLLERS SHAFTS..................................................................149

8.37 REMOVAL AND INSTALLATION OF REJECT POCKET ENVELOPE .............................................................152

8.38 REMOVAL AND INSTALLATION OF PRESSING SHAFT UNIT ....................................................................154

8.39 REMOVING AND INSTALLING PU ROLLERS SHAFT................................................................................156

8.40 REMOVING AND INSTALLING PU ROLLERS SHAFT (NO.2) ...................................................................158

8.41 REMOVAL AND INSTALLATION OF UPPER ENVELOPE ASSEMBLY..........................................................160

8.42 DISASSEMBLY AND ASSEMBLY OF HOPPER UNIT..................................................................................163

8.43 DISASSEMBLY AND ASSEMBLY OF TOP COVER UNIT ASSEMBLY...........................................................174

8.44 DISASSEMBLY AND ASSEMBLY OF REJECT POCKET ASSY .....................................................................178

8.45 DISASSEMBLY AND ASSEMBLY OF SEPARATOR COVER UNIT ................................................................184

8.46 DISASSEMBLY AND ASSEMBLY OF SEPARATOR BRACKET ASSY............................................................186

8.47 DISASSEMBLY AND ASSEMBLY OF STACKER UNIT................................................................................193

8.48 DISASSEMBLY AND ASSEMBLY OF PSU ...............................................................................................199

8.49 DISMANTLING AND ASSEMBLING OF CIS FRAME ASSY ........................................................................205

8.50 DISASSEMBLY AND ASSEMBLY OF REAR FRAME ASSY .........................................................................211

8.51 DISASSEMBLY AND ASSEMBLY OF STACKER SHAFT .............................................................................228

8.52 ASSEMBLY AND DISASSEMBLY OF LOWER ENVELOPE IN AN ASSEMBLY...............................................232

8.53 DISASSEMBLY AND ASSEMBLY OF UPPER ENVELOPE............................................................................238

8.54 REPLACEMENT OF DISPENSING ROLLER GLIDES ...................................................................................240

8.55 DISASSEMBLY AND ASSEMBLY OF RIGHT WALL UNIT...........................................................................241

8.56 DISASSEMBLY AND ASSEMBLY OF LEFT WALL UNIT.............................................................................250

9PRODUCT ADJUSTMENT.....................................................................................................................254

9.1 ADJUSTMENT OF MISALIGNMENT OF SEPARATOR BRACKET UNIT.........................................................254

9.2 ADJUSTMENT OF MAGNET SENSORS POSITION......................................................................................257

9.3 FUNCTIONAL TESTING OF MAGNET SENSORS........................................................................................271

9.4 MAGNET SENSORS INTRINSIC NOISE TEST ............................................................................................274

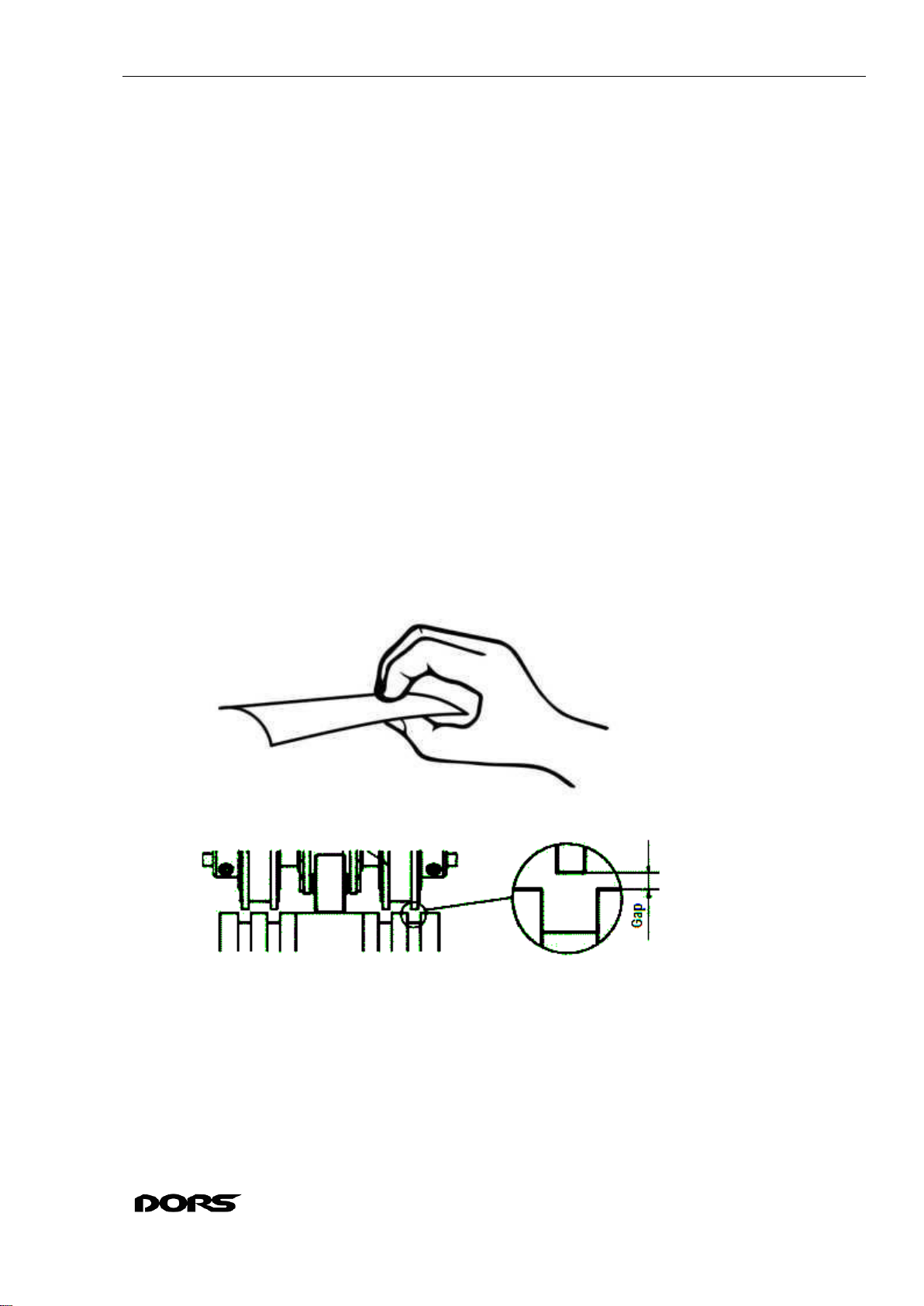

9.5 ADJUSTMENT OF THE GAP BETWEEN THE ROLLERS ..............................................................................277

9.6 REDIRECTOR ADJUSTMENT ..................................................................................................................278

9.7 LOWER ENVELOPE ASSEMBLY POSITION ADJUSTMENT.........................................................................283

9.8 OPENING SENSOR MODULE POSITION ADJUSTMENT..............................................................................286