Metering Tip Selection:

The nal concentration of the dispensed solution is related to

both the size of the metering tip opening and the viscosity of

the liquid being siphoned. For water-thin products, the chart

at right can be used as a guideline. If product is noticeably

thickerthanwater,consulttheMeasurementofConcentration

Procedure below to achieve your desired water-to-product

ratio. Because dilution can vary with water temperature and

pressure, actual dilution achieved can only be ascertained

by using the Measurement of Concentration Procedure. The

clear, undrilled tip is provided to permit drilling to size not

listed should you need a dilution ratio that falls between

standard tip sizes.

NOTE: Refer to parts diagram if unfamiliar with names of

system components.

Measurement of Concentration:

You can determine the dispensed water-to-product ratio for

anymeteringtip size andproduct viscosity. All that is required

is to operate the primed dispenser for a minute or so and note

twothings:theamountofdispensedsolution,andtheamount

of concentrate used in preparation of the solution dispensed.

The water-to-product ratio is then calculated as follows:

Dilution Ratio (X:1) where X = Amount of

Mixed Solution — Amount of Concentrate Drawn

Amount of Concentrate Drawn

Dilution Ratio, then, equals X parts water to one part concen-

trate (X:1). If the test does not yield the desired ratio, choose a

dierent tip and repeat the test. Alternative methods to this test are 1) pH (using litmus paper), and 2) titration. Contact your concentrate supplier

for further information on these alternative methods and the materials required to perform them.

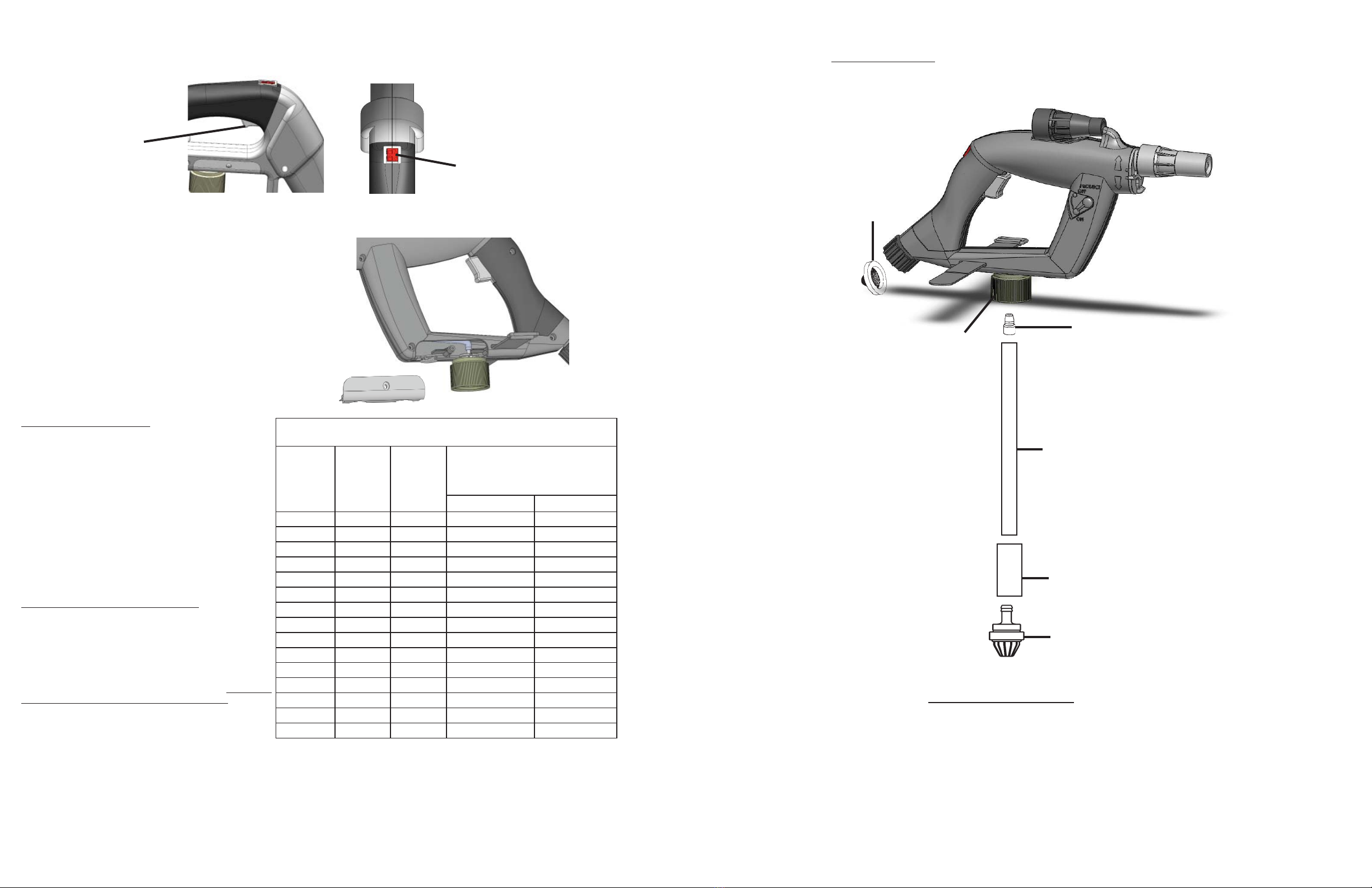

Parts Diagram List:

1 238100 Strainer washer

2 10092189 Kit, cap replacement

3 690014 Metering tip kit

4 10027303 Pick-up tube, 12"

5 509900 Ceramic weight

6 10089410 Footvalve, Viton

* EPDM also available order 10076302

DescriptionPart No.Key

5

4

6

3

1

2

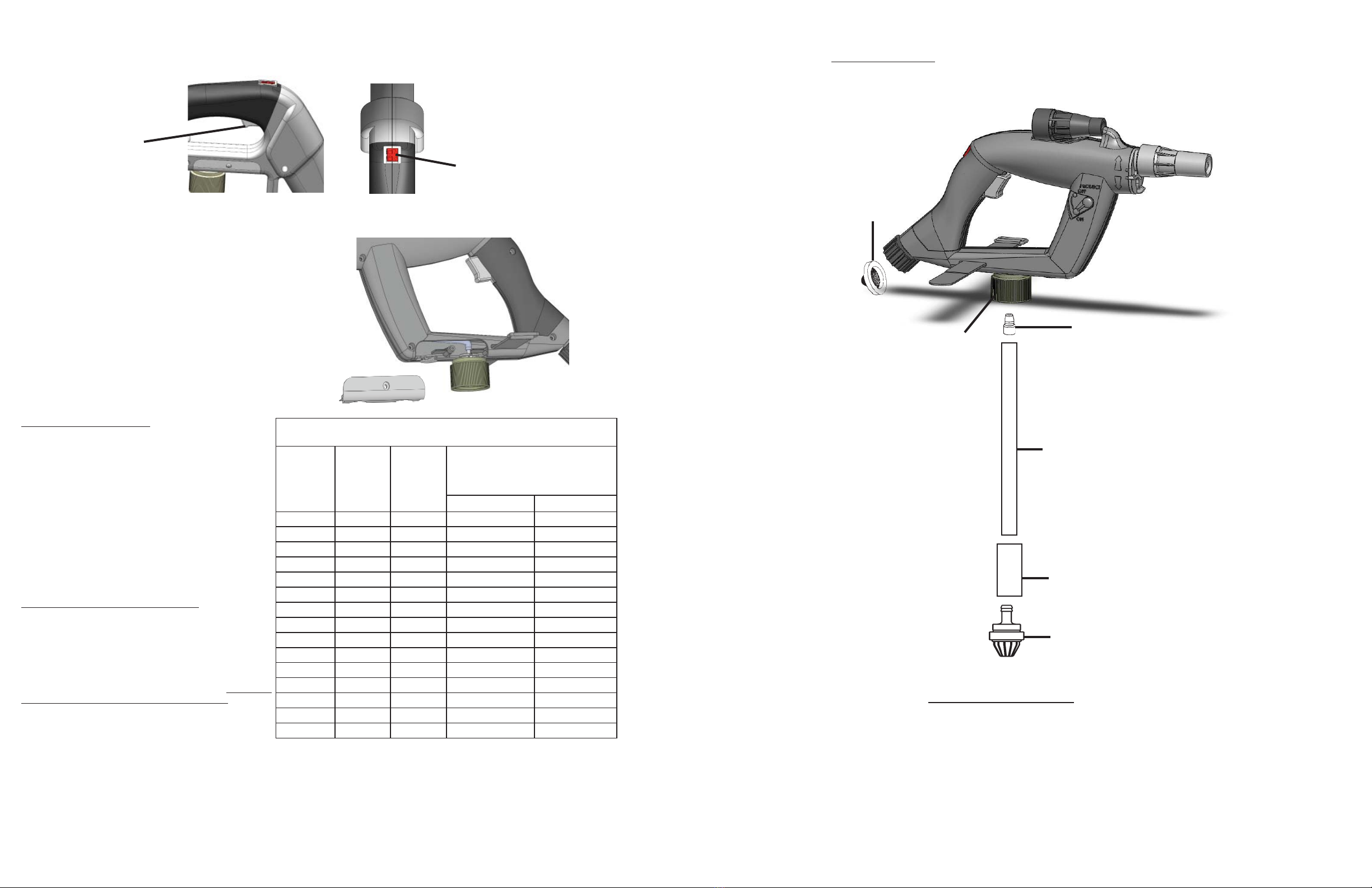

7. Depress trigger to begin dispensing desired concentrate solution; release trigger to stop flow of solution. To lock trigger

in "ON" position depress and hold trigger while sliding red lock button back then release trigger. To release lock push red

lock button up and slightly forward to stop flow of solution.

7. To disconnect, turn off water source. Make sure on/off valve is in OFF position. Disconnect water supply hose from unit.

TRIGGER

LOCKBUTTON

8. Bottle Conversion.

Your dispenser was delivered to fit an "F-Style" or

"Round Gallon" bottle. The cap can be converted from

one style to the other by removing the screw to the

cover,andrelocatingthecap.Replacethebuttoninsert

into the open hole. Then reinstall the cover and screw.

APPROXIMATE DILUTIONS

AT 40 PSI FOR WATER-THIN PRODUCTS (1.0 CP)

Tip

Color Orifice

Size Std. Drill

Number

Ratio

(per Eductor Flow)

2.5 GPM

Foamer Sprayer

No Tip .187 (3/16) 7:1 13:1

Grey .128 (30) 7.5:1 13:1

Black .098 (40) 8:1 13:1

Beige .070 (50) 8:1 15:1

Red .052 (55) 11:1 17:1

White .043 (57) 15:1 22:1

Blue .040 (60) 18:1 24:1

Tan .035 (65) 22:1 32:1

Green .028 (70) 32:1 46:1

Orange .025 (72) 45:1 57:1

Brown .023 (74) 49:1 64:1

Yellow .020 (76) 73:1 76:1

Aqua .018 (77) 82:1 87:1

Purple .014 (79) 140:1 140:1

Pink .010 (87) 280:1 280:1