D+H RZN 4402-K User manual

99.821.26 3.8/08/06

Instruction for use

D+H Mechatronic AG • Georg-Sasse-Str. 28-32 • D-22949 Ammersbek • Tel. +4940-60565219 • Fax +4940-60565264

RZN 4402-K

RZN 4404-K RZN 4402-KS

RZN 4404-KS

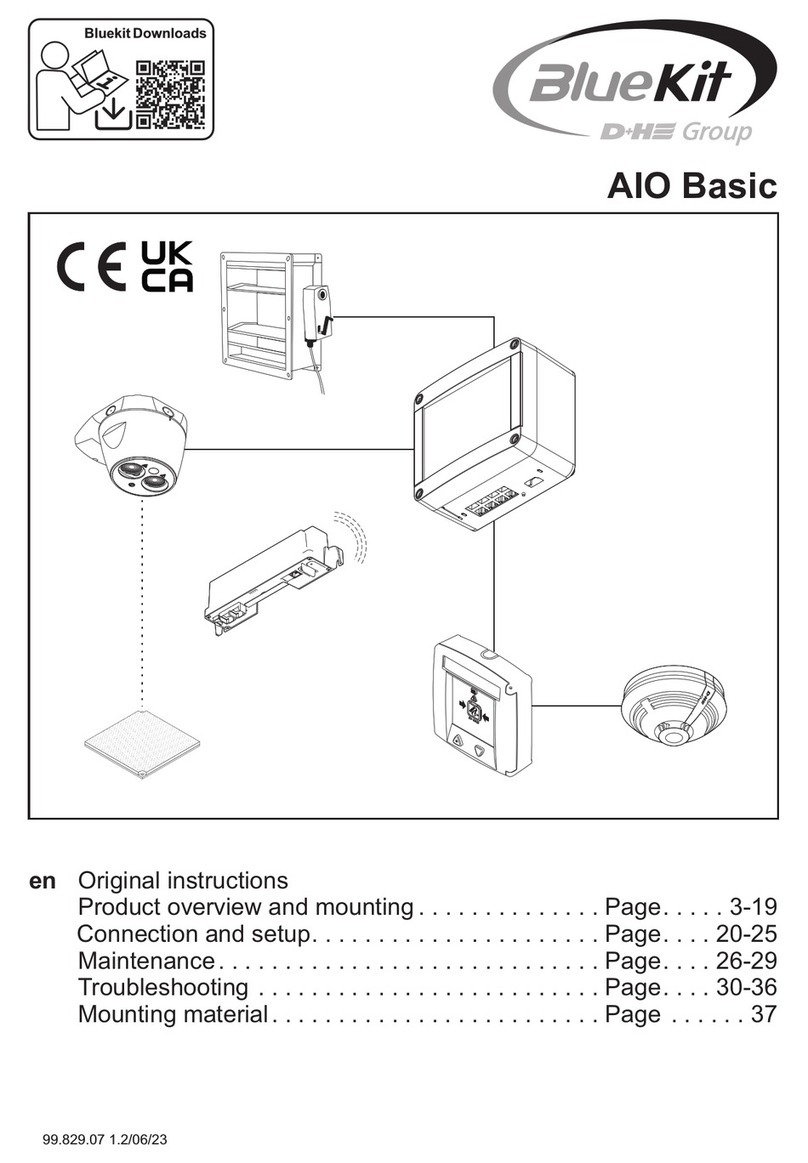

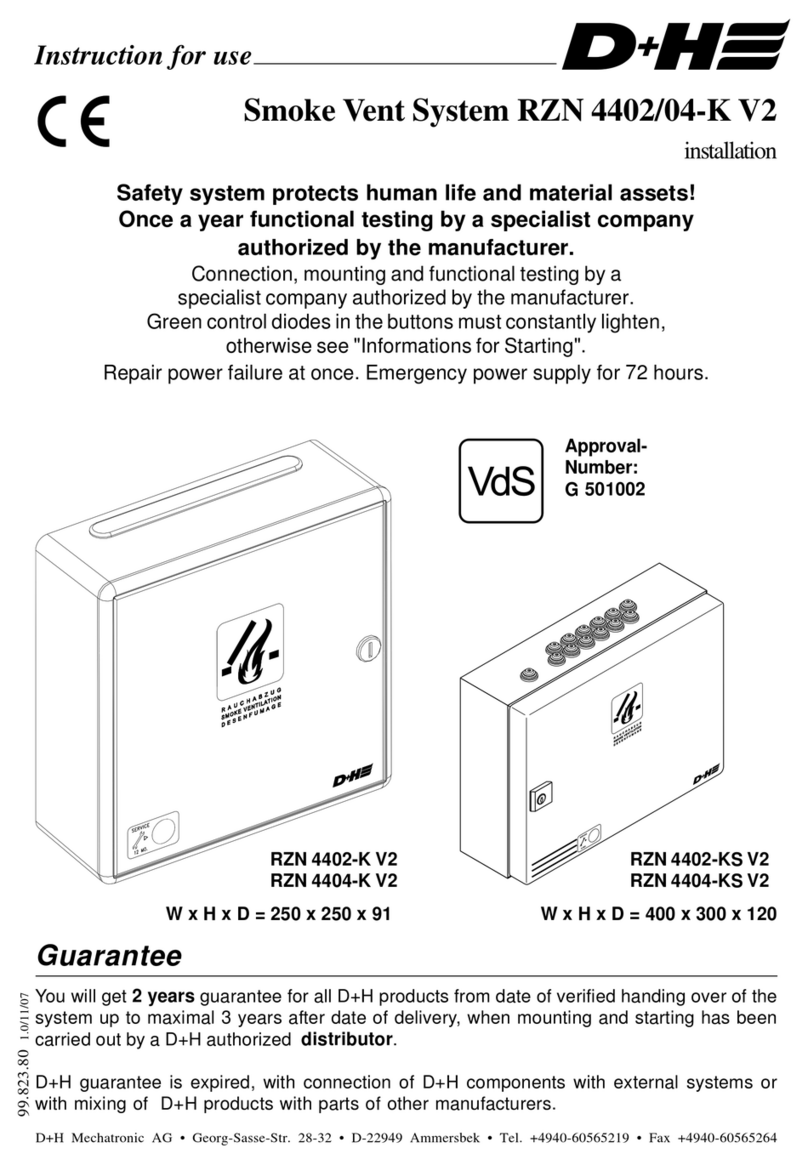

Smoke Vent System RZN 4402/04-K

installation

Safety system protects human life and material assets!

Once a year functional testing by a specialist company

authorized by the manufacturer.

Connection, mounting and functional testing by a

specialist company authorized by the manufacturer.

Greencontroldiodesinthebuttonsmustconstantlylighten,

otherwise see "Informations for Starting".

Repair power failure at once. Emergency power supply for 72 hours.

Approval-

Number:

G 501002

Guarantee

You will get 2 years guarantee for all D+H products from date of verified handing over of the

system up to maximal 3 years after date of delivery, when mounting and starting has been

carried out by a D+H authorized distributor.

D+H guarantee is expired, with connection of D+H components with external systems or

with mixing of D+H products with parts of other manufacturers.

W x H x D = 250 x 250 x 91 W x H x D = 400 x 300 x 120

2/20 RZN4402/04-K Rev.:3.8

TechnicalData

Control panel type : RZN 4402/4404-K / KS

Rated voltage : 230VAC, 50Hz

Rated capacity : 60VA/120VA

Interfering

emission : EN 50081-2

EN 55022

Res. to jamming : EN 50082-1

EN 61000-4-2 to -6

EN 50204

Protective category : II/I

Fire resistance : -5 to +40 °C

Protective system : IP30 / IP54

Class of rating

- Monitoring : Continuous duty

- Emergency state/

ventilation : Short-time duty

Output voltage : 24VDC /

res. ripple <10%

Safe output

- rated current : 2A/4A

VdS approval No : G 501002

Content

Guarantee ................................................. 1

Technical Data, Maintenance ................... 2

Introduction................................................ 3

System overview ....................................... 4

Mounting of housing .............................. 5-6

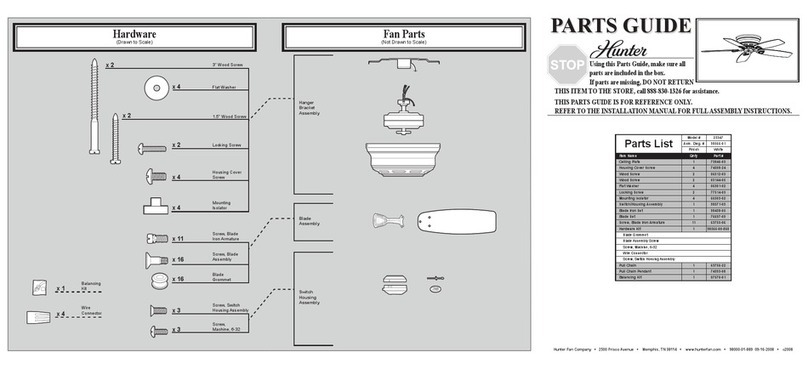

View motherboard RZN 4402/04-K.......... 7

Drives and smoke vent buttons ............... 8

Wiring plan ................................................ 9

Connection cable .................................... 10

Connection......................................... 11-17

Starting .................................................... 18

Encode of line and group ....................... 19

Examination ............................................ 20

Maintenance

Onceayear by a specialist company,whois

authorized by the appliance manufacturer.

Renew test badge, keep control book.

The respective current D+H maintenance

instruction is decisive.

D+H authorized expert companies have

been specially trained by D+H for carrying

out expertly this maintenance, and they get

automatically the latest maintenance

instructions.

Following tests must be carried out in the

course of maintenance:

- Outside examination / inspection of

system components

- Measuring of insulation resistances

- Checking of all relevant power supply units

- Functional testing of connected system

components

- Record of competent carrying-out of

maintenance, and designation according

to directions

Information

An overdue maintenance of the system will

be indicated by the control panel after about

ca. 14 to 16 months. The yellow diode in the

smoke vent button RT 43-H will start flashing.

A malfunction in the smoke vent system will

be continually indicated by the extinguished

green control diodes in the smoke vent

buttons.

After the maintenance time is expired (ca.

14 to 16 months), the ventilation function

OPEN can be interrupted depending on the

presetting of the service timer. Reset can be

carried out by a specialist company only, who

has been authorized by the appliance

manufacturer.

24 V Emergency Supply

Emergency power supply for 72 hours. Use VdS approved storage batteries only.

RZN 4402-K:

2x 12V / 1,2Ah ±0,2Ah (Type 1)

With connection of alarm devices:

2x 12V / 2,2Ah ±0,3Ah (Type 2)

RZN 4404-K:

2x 12V / 2,2Ah ±0,3Ah (Type 2)

With connection of alarm devices:

2x 12V / 3,4Ah ±0,3Ah (Type 8) *

* Attention! Bigger housing necessary!

3/20

RZN4402/04-K Rev.:3.8

Important Regulations

Observe regulations for danger warning systems VDE 0833, guidelines for electrical systems

VdS 2221, VDE 0100, DIN 18232 for smoke and heat vent systems, regulations of the local

fire-brigade and of EVU for connection to mains supply.

Introduction

Smoke and heat vent systems (RWA´s) are very important

elements of structural preventive fire protection.

Smoke and heat vent systems are appliances of preventive fire protection. They fulfil important

functions in case of fire: protection of human life by providing a smokeless layer, by which

rescue routes are kept free for the fire-brigade. Consequential damages by conflagration

gases are reduced, and therefore, considerable material assets are often protected from

destruction. Precondition for this is, that the systems will function absolutely reliable in a

case of fire. Only electrical specialist companies are authorized to install these systems,

who have electrical specialist staff with relevant experiences in installing danger alarm

systems or smoke and heat vent systems. Only these ones can take on responsibility for

functioning, and can ensure product liability for the whole system (see product liability law

BGBL.I S.2198 and BGB (bodily injury, compensation for damage)).

Therefore, regular maintenance and checking of functional readiness is imperative and has

to be ensured. These standard requirements are demanded according to regulations of the

DIN, of the Association of German Insurer against damage of property (VdS) and the

respective local authorities. Recommended is, that maintenance work should be carried

out by authorized specialist companies, only.

Only regular and professional maintenance warrants

the necessary and permanent functional safety.

Only authorized specialist companies are allowed to install and maintain smoke and heat

vent systems and system components, constructed and distributed by D+H Mechatronic

AG. All D+H Mechatronic AG partners belong to these authorized specialist companies,

who regularly undergo an in-house training to ensure their qualification and experience.

Smoke and heat vent systems must be maintained at annual intervals by authorized special-

ist companies according to DIN 18232 section 2 paragraph 10.2, and VDE 0833 section 1

paragraph 5.3.4 for alarm systems and manufacturer guidelines.

According to DIN VDE 0108 section 1 paragraph 9.1.1 accumulators for emergency supply

(lead accumulators) must be checked every six months by a person, who has been introduced

to this task, and once a year, maintenance must be carried out by specialist companies.

Accumulator types, which are used for D+H Mechatronic AG smoke and heat vent systems

must be VdS approved, and must be released by D+H Mechatronic AG to use in smoke and

heat vent systems. According to DIN 18232 section 2 paragraph 10.2 the tests must be put

down in an operational book, which the operator/ building owner must present to the building

supervision authority on request. This operational book is available at D+H (Ord.-No.:

68.700.15)

Executed maintenance must be proved by a D+H Mechatronic AG maintenance/ and testing

confirmation.

4/20 RZN4402/04-K Rev.:3.8

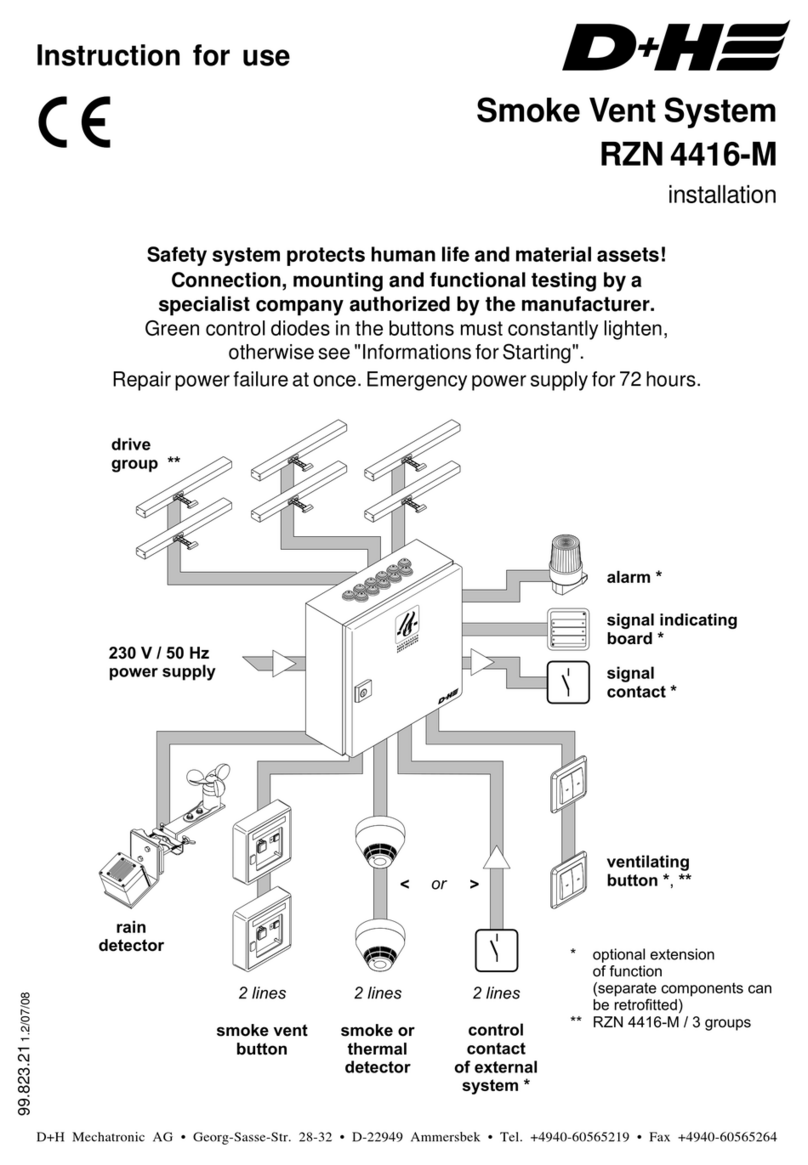

* optional function extension

(separate components. Retrofitable!)

System Overview

Drive group

signal

indicating

board*

acoustical+

optical alarm

devices*

signal

contact*

230V / 50Hz

Mains supply

wind/rain

transmitter*

smoke vent button

(min. 2 piece) ventilating

button*

smoke or

thermal

detector*

control contact of

external system*

5/20

RZN4402/04-K Rev.:3.8

Recessed dimension for flush mounting

W x H x D : 262 x 262 x 81mm

Mounting of housing 1

joint rod

door

plaster cross for

flush mounting*

cable cover

cable bushing

(only surface mounting)

housing

flush mounted

wall hook*

* optional flush mounted set UPS 44-K

(not for hollow wall mounting)

flush mounted frame

(288x288mm)*

surface mounted

frame

6/20 RZN4402/04-K Rev.:3.8

Mounting of housing 2

Mount control panel sheltered and easily

accessible for maintenance in proximity of

drive

Surface mounting:

1.Remove cable cover

2.Fasten housing trough with 4 screws at

wall

Flush mounting

(not hollow wall mounting):

1.Screw down wall hook and plaster cross

at housing trough

2.Fasten housing trough in niche and

remove plaster cross again after

plastering

Attention: Fire resistance category of fire

walls must not be inadmissibly influenced.

Sound insulation is impaired by flush

mounting.

Final mounting:

3.Mount and connect central pcb

4.Screw down cable cover

5.Unhinge door of the door frame (for this,

press joint rod upwards using pliers).

Fasten door frame on housing trough, and

hangdooron it’shinges again

Piktograph explanation

Smoke and heat vent alarm

Control panel O.K.

Fuse actuator

Mains existing

Vent button function "ON"

Vent button function "OFF"

Charging voltage controller

Battery

Fastening of accumulators

Only RZN 4404-K.

Covering

Place enclosed covering cap over supply

terminalaftermainscablehasbeenconnected.

7/20

RZN4402/04-K Rev.:3.8

accumulator

charging voltage control

Fuses: dimension 5 x 20mm

Class of rating and rated power is indicated

on cover plate in control panel.

View motherboard (RZN 4402/04-K)

fire recognition

element (thermo

maximum signal)

fuse drive

fuse external

detector

Dip switch

mainsconnection

LED-failure,

group

LED-

control

LED-failure

line

fuse mains

RZN 4402/ 04-K = T0,63A

covering

fuse accumulator

LED-failure

accumulator

connection

accumulator

LED-mains

8/20 RZN4402/04-K Rev.:3.8

Smoke Vent Button

Place(s) of mounting:

Maximal 8 smoke vent buttons can be

connected.

Maincontrol mustbemountedon ground-floor

according to VdS 2221.

Secondarycontrol isto beinstalled inall other

floor levels according to VdS 2221.

Install buttons so, that they are accessible

any time and clearly visible.

Mounting height:

1,5m above upper edge of firm flooring.

Fastening:

With plug screws 4,5 x 40mm diagonal, or

direct on 55mm flush box with 2 screws.

Housing colour:

Standard:deeporange (RAL2011),

according to VdS 2592.

However, deviating colours might be locally

required (blue,yellow, red).

Please consult your D+H distributor.

Drives

Smoke and heat vent opening:

Smoke gases are to be carried off as

unhindered as possible through smoke and

heat vent opening in case of fire.

According to relevant rules, openings have

to be placed always in the upper part of a

building.

The smoke and heat vent opening can be

mounted in the wall as well as in the ceiling.

Size, kind and arrangement of the opening

is of decisive significance for an optimal

effect of the smoke and heat vent system.

The important thing here is, that an escape

must not be hindered by the window wing

itself, by structural facts like offsets, or the

like.

Minimum ventilating surface is given by le-

gal regulations and structural facts. The

smoke vent opening must be at least 1m² or

5% of the basis, dependent on the LBO.

The valuated sizes of opening angles of

smoke and heat vent systems must be in

agreement with the responsible fire

protection authority.

Observe! Window wings, opening inward,

must not project in escape/ and rescue

routes and obstruct them.

Mounting of the drives:

Please take mounting informations from the

relevant instruction for use of the respective

drive, because of varied possibilities for

choosing drives.

ATTENTION:

When Dip switch 10 is on ON, the smoke

vent will be triggered with an OPEN-

impulse every 2 minutes for a duration of

30 minutes according to VdS 2581. For this,

the drive must be blockage safe according

to VdS 2580 par. 4.7. .All D+H drives meet

this precondition. Otherwise Dip switch 10

is to be switched on OFF.

9/20

RZN4402/04-K Rev.:3.8

M

230VAC

24VDC

Brandmelder

Zentrale

Antrieb

230V 50Hz

nicht abschaltbar

Kontakt

Fremdansteuerung

Rauchabzugstaster

Rauchabzugstaster

zu weiteren

zu weiteren

M

IY (St) Y

2x2x0,6

IY (St) Y

2x2x0,6

IY (St) Y

2x2x0,6

IY (St) Y

4x2x0,6

IY (St) Y

4x2x0,6

230VAC

24VDC

siehe Kabelverlegetabelle

im obersten bewohnten Geschoss

im EG

Lüftungstaster

Legend

Drive 24 VDC at smoke vent flap

(lines must end in flush

mounted distribution box, see

symbols above).

RZN surface or flush type

(230 VAC / 24 VDC)

in proximity of smoke vent flap.

Smoke vent button

(e.g.RT 43-H/N)surface 24VDC

circa 1,5m above upper edge

firm flooring (by customer 55mm

flush socket)

Vent button 24 VDC (e.g. LT 43)

circa 1,2 above upper edge firm

flooring (at flush type by others

55mm flush socket)

Fire detector 24 VDC

(e.g. FO 1362 or FT 1262)

Wiring Plan (Paragon)

Drive see cable wiring table

to further ones

to further ones

Control

panel

not possible to switch off

Fire detector

Ventilation

button

Contact external control

230 V Supply

Provide for separate electric circuit.

Mark fuses.

Plug covering cap over mains binder on

motherboard of control panel.

Connecting cable: NYM-I3x1.5

Connecting load: RZN 4402-K = 60 VA

RZN 4404-K = 120 VA

Weak Current Lines

Install and feed separately from supply

mains.

Mark cable and terminal box red.

Secondary control

Main control

10/20 RZN4402/04-K Rev.:3.8

Typ / type

Antriebe / 0,5A 12345678

drives 1A 1234

3 x 1,5mm² 240 120 80 60 48 40 34 30 m

3 x 2,5mm² 400 200 130 100 80 65 55 50 m

*5 x 2,5mm² 800 400 260 200 160 130 110 100 m

RZN 4402-KRZN 4404-K

Detector Cables (Line):

The detector cables are monitored for short

circuit and for break.

The opening device is automatically

triggered and opens up in case of fault, when

DIP-switch 7 is on ON.

Smoke vent button cable and cable of

automatic detectors:

- weak current sheathed flexible cable YR

6 x 0.8

or

- house wiring cable IY(ST)Y 4 x 2 x 0.6

Cables through areas not monitored:

An increased time of functioning of the cable

canbe required,when drivelines areinstalled

throughbuildingparts,whicharenotmonitored.

- Safetyline withfunctional conservation

... E90, according to DIN 4102* or standard

guidelinesfor line systemsMLAR.

(see supplementary sheet 1 to DIN VDE

0108)

* Notice: No type designation is given

for these cables, because of a large

variety on the market. Please consult

your D+H distributor about these.

The smoke vent control panel is designed

for opening smoke vent devices, which

operate by thermal ascending force and by

automatic fire recognition devices (thermal

detector, smoke detector), and they release

either self-acting or manual by smoke

detectors at an early stage of a fire, and

remain in opened position without further

power consumption. In these cases,

functioning preservation of the electrical line

system is required only at an early stage of

fire. Protected wiring is required with

protection against mechanical damages

according to DIN 18232 section 2.5.5

paragraph 4.

Control Cable (Group):

Cable from the smoke vent control panel to

connection of drive (drive lines have a

monitoring wire, in which fire recognition

devices (thermal maximal detector e.g. THE)

canbe looped-in):

- Safetyline, withfunctional conservation

... E30, according to DIN 4102* or standard

guidelines for line systems MLAR.

Cable for D+H Smoke and Heat Vent Systems

cross section (mm²) = plain cable length (m) x number of drives

80**

* Connect in parallel 2 wires for each drive line.

** Only valid for drives with 1A actuating current. Use „160“ for drives with 0,5A actuating current

and „230“ for drives with 0,35A actuating current.

Line lengths and Cross sections:

Number of wires and cross-sections indicated, refer to required lines only. In case of

using a line with earthed conductor (green/ yellow), this one will not be counted in and

must not be wired.

11/20

RZN4402/04-K Rev.:3.8

Standard Connection with RT 42

* Terminal resistors for line monitoring:

They are pinched in control panel for transport. Take it off there and connect according to

plan. Terminal resistors must remain at binder RM 1,2, when no fire detector or external

control exists.

**Fire detectors

Only D+H system approved detectors must be used (see page 16).

Lengthoflineand

cross sections, see

page 10

12/20 RZN4402/04-K Rev.:3.8

Parallel Connection of Smoke Vent Buttons - RT 42

13/20

RZN4402/04-K Rev.:3.8

Standard Connection with RT 43-H/-N

* Terminal resistors for line monitoring:

They are pinched in control panel for transport. Take it off there and connect according to

plan. Terminal resistors must remain at binder RM 1,2, when no fire detector or external

control exists.

**Fire detectors

Only D+H system approved detectors must be used (see page 16).

Lengthoflineand

cross sections, see

page 10

14/20 RZN4402/04-K Rev.:3.8

Connection of 2 Smoke Vent Buttons - RT 43-H/-N

12345678

RZN 4402/ 04-K

line

line

–

–

control

alarm

close

RM/RT

smoke vent button

RT 43-H

smoke vent button

RT 43-N

10kW

10kW

alarm

alarm

control

control

-

-

line

line

line

line

malfunction

close

close

22

7

8733116644

alarm

alarm

close

close

red

red

green

green

yellow

* shunt connection by customer

malfunction

*

*

15/20

RZN4402/04-K Rev.:3.8

Parallel Connection of

2 x 2 Smoke Vent Buttons - RT43-H/-N

16/20 RZN4402/04-K Rev.:3.8

Connection of magnetic clamps on RZN 4400-K

Low tension side

in neutral position

in case of power failure!

Magnetic clamps 24V

(max. 500mA

overall power)

-+

-+

N- N+ Z + M D1 D2

Cutout

button

Magnetic

clamp

*The resistor must not be used, when line connections with 2-detector dependency are

employed!

Connection of several fire detectors

Connection of one fire detector

terminal resistor

line

-

10K

single fire detector

180R

1

2

3

4

5

6.

7

*

line

-

10K

first fire detector second to penultimate

fire detector

ultimate

fire detector

180R

1

2

3

4

5

6.

7

*180R

1

2

3

4

5

6.

7

*180R

1

2

3

4

5

6.

7

*

terminal resistor

17/20

RZN4402/04-K Rev.:3.8

M

M

ZentraleAbzweigdose

Abzweigdose

amMotor

weitereAbzweige

gleichartig schalten

Abzweigdose

amMotor

Abzweigdose

br.

br.

bl.

bl.

7

6

5

MMMMM M M M

3x2,5²

25m

M M M M M M M M

4x2,5²3x2,5²

50m50m

MMMMM M M M

3x2,5²

4x2,5²

40m

75m

M M M MM M M M

4x2,5²

5x2,5²

75m75m

200m

controlpanel branchbox

connectinthe

samewayfurther

derivations

branchbox

branchbox

atdrive

branchbox

atdrive

Connection Examples

Connection with line derivation:

supply wires Mot a / Mot b derive off in par-

allel, monitoring will be looped through all

cables up to group end.

Example 1: 1 line

Simple installation, but unfavourable for

voltage drop: All drives on one line.

Example 2: 2 lines

Control panel in centre, one side wired as

derivation, the other as terminal line.

Observe 4 wires for derivation!

Example 3: 2 lines on one side

Derivation and terminal lines in same

direction; number of drives vary according

to length of line.

Observe 4 wires for derivation!

Example 4: 3 lines

3 lines are installed due to extremely long

distances: 2 lines with 3 drives each on 75

m line as derivation, and 1 line with 2 drives

on 200 m line.

Observe 4 wires for derivation!

18/20 RZN4402/04-K Rev.:3.8

123456789

10

ON

yes

no

Factory-set?

(Dip switch)

yes

Adjust Dip switch S1 on

motherboardasfollows:

Informations for Starting

Carry out following sight and performance checks for switching-on the smoke and heat vent

control panel. no

yes

yes

yes

yes

yes

yes

no

no

no

no

no

no

All cable

connected?

Partial or incomplete connection of components can

cause malfunction..

Check following connections: mains 230V, drives,

smoke vent buttons, when necessary fire detectors

and vent buttons. See wiring and connection plans

page 9 and 11-14.

All necessary moving loads connected?

Smoke vent components are line-monitored.

A malfunction is connected as alarm in delivery condition of

control panel. The smoke vent opens self-acting and can be

reset under special conditions only.

Performance check alarm/reset and ventilation

10kΩresistance in

smoke vent button?

10kΩresistance in

fire detector?

Stop module 2x47kΩ

in conduit box?

Connect mains

mains control

lightens?

Connect

accumulator lines control

lightens?

Smoke vent flap

opens and closes?

Cramp stop module on last or only drive in conduit box

on wire 5 yellow, 6 black, 7 black. See connection plan

page 11/ 13.

Check line safety fuse in E distribution and fuse mains

in control panel.

Mains still not available or line switch

on "0" or one of fuses faulty.

Resistance must be cramped in electric last button on

binding posts 3/ 8 (RT 43-H) or binding posts 3/ 7

(RT 42). See connection plan page 11-14.

Resistance must be cramped in last or only fire detector

on binding post 2 and 4 (type FO/FT). Resistance

remains in control panel between binding post RM 1

and 2, when no fire detector available.

See connection plan page 11-14.

Possibly change poles in drive.

19/20

RZN4402/04-K Rev.:3.8

123456789

10

ON

Dip switch 1 on ON = OPEN-running time limitation. Using a potentiometer

sec

20

260

40

, running time

in Open direction can be limited. If the vent button is actuated in Open

direction, the drive will run open as long as the running time is set.

Dip switch 2 on ON = Ventilation time limitation. Using a potentiometer

min

15

245

30

, ventilation time

can be set. Drives will automatically close again, after the adjusted time has

expired.

Dip switch 3 on ON = OPEN-retriggering. If Dip switch 1 is switched on ON, the OPEN-running

time limitation can be retriggered again.

Dip switch 4 on ON = Power failure-CLOSED. If the power supply breaks down, the drive will

close. Only if Dip switch 5 = ON

Dip switch 5 on ON = Ventilation flap close up to final position by single pressing on vent button.

When dip switch 5 is switched on OFF, flaps are closing only so long as the vent button

or the button in the smoke vent button is pressed.

OPEN-display on vent button is no longer possible then! If Dip switch 5 is on OFF, the

function power failure-CLOSED will be ineffective (see Dip switch 4).

Dip switch 6 on ON = Ventilation flap opens up to final position by single pressing on vent

button.

If Dip switch 6 is connected on OFF, the flaps will only open as long as the vent button is

pressed.

Dip switch 7 on ON = The control panel will be switched on alarm, that means the smoke

vent opens at a line fault (e.g. at an interrupted detector line or short

circuit).

Dip switch 8 on ON = The control panel will be switched on alarm, that means, the smoke vent

opens in case of group fault (e.g. in case of an interrupted control line).

Dip switch 8 must be on ON in conjunction with a ground in thermal maximal

detector (e.g. THE 4).

Dip switch 9 on ON = Smoke detector alarm can not be reset by single pressing on button in

smoke vent button.

Dip switch 9 must be switched on OFF, when remote reset is desired of smoke detectors

by the smoke vent button.

Dip switch 10 on ON = The smoke vent is triggered for a duration of 30 minutes in intervals of

2 minutes according to VdS 2581.

Encode of Line and Group

Following functionings can be set with Dip switch (S1) on motherboard.

Set position of

Dip-switch at delivery:

20/20 RZN4402/04-K Rev.:3.8 All sizes in millimetre • Rights to technical modifications reserved. • Reprintingandphototechnical

reproduction also in extracts has to be expressively authorized by D+H Mechatronic AG.

Preparation:

Notifyuser,that thesystem isoutof operation

before starting with inspection.

Notify user about false alarms.

Interrupt or switch off monitored alarm

indication and remote controls.

Information

An overdue maintenance of the system will

be indicated by the control panel after about

16 months. The yellow control diode in the

smoke vent button RT43-H will start flashing.

A malfunction in the smoke vent system will

be continually indicated by the extinguished

green control diodes in the smoke vent

buttons.

After the maintenance time is expired (ca.

14 to 16 months), the ventilation function

OPEN can be interrupted depending on the

presetting of the service timer. Reset can be

carried out by a specialist company only, who

has been authorized by the appliance

manufacturer.

Inspection:

Check all appliances and cable connections

for outer damage and dirt accumulation.

Fire detectors, smoke vent buttons, smoke

vents and so on must not be impaired in

their function by goods in storage or

structural changings.

Smoke vent button:

Open smoke vent button.

Press red button , red display diode

lightensin buttonand controlpanel.

Smoke vent must open.

Press masked button (1 sec.), red display

diode extinguishes in button and control

panel.

Smoke vent must close.

Automatic fire detectors:

Release smoke detector individual by D+H-

smoke detector tester, as an alternative by

cigarette smoke (response delay circa 20

sec.).

Red display diode must lighten.

Smoke vent must open.

For closing wait until there is no more smoke

indetector.

Reset line in control panel (switch off/ switch

on press button), red display diode

extinguishes in button and control panel.

Press masked button in smoke vent

button. Smoke vent must close.

The line can also be directly reset via smoke

ventbutton,if Dip switch9 isswitchedonOFF.

For this, press masked button in smoke

vent button (for 1second).

Red display diode extinguishes in button

andin controlpanel.

At severe dirt accumulation visible from

outside, send detector in for maintenance

and install another one.

External control (optional):

Release external control.

Smoke vent must open.

Open contact in external system for closing,

for example by resetting of fire detector

system.

Pressmasked button insmokevent button

(1second).Reddisplay diode extinguishes

inbutton andcontrol panel.

Smoke vent must close.

Emergency supply:

Detach fuse MAINS on motherboard of

control panel.

Greenmainsindicationdiode on control

panel must not lighten.

Repeat functioning testing.

Green control diode in smoke vent

buttons must not lighten.

If Dip switch 4 and 5 on ON, the group will

be automatically closing.

Examination

Every six months and after repair by a specialist or staff, who has been introduced to the task.

Eliminatefailingsatonce.Keepcontrolbook.

This manual suits for next models

3

Table of contents

Other D+H Fan manuals

Popular Fan manuals by other brands

Inspire

Inspire Ana JB36301 Assembly, Use, Maintenance Manual

Panasonic

Panasonic FV-0810RS1 Service manual

Optimus

Optimus F-4184 instruction manual

NuAire

NuAire MRXBOXAB-ECO4-1Z installation manual

Greenheck

Greenheck ASSURE-120S-S1 Installation, operation and maintenance manual

DYNABREEZE

DYNABREEZE FA-26243 Instructions & user's manual

Stingray

Stingray ALVA Air ACS205 manual

Helios

Helios ultra Silence MiniVent M1/150 N / C Installation and operating instructions

ECG

ECG FT 15a instruction manual

Craftmade

Craftmade Pavilion PV52 instruction manual

Faro Barcelona

Faro Barcelona Poros 33524 installation guide

Casablanca

Casablanca Crestmont 55063 owner's manual