3

Contents

Page

Conformity declaration 2

Contents 3

1.0 Symbol- and Pictograph description 4

1.1 Function description 4

2.0 General instructions 5

2.1 Technical description 5

2.2 Application 5

2.3 Safety 6

3.0 Transport and storage 6

3.1 Transport 6

3.2 Storage 6

4.0 Main dimensions and technical data 7

4.1 Dimensions 7

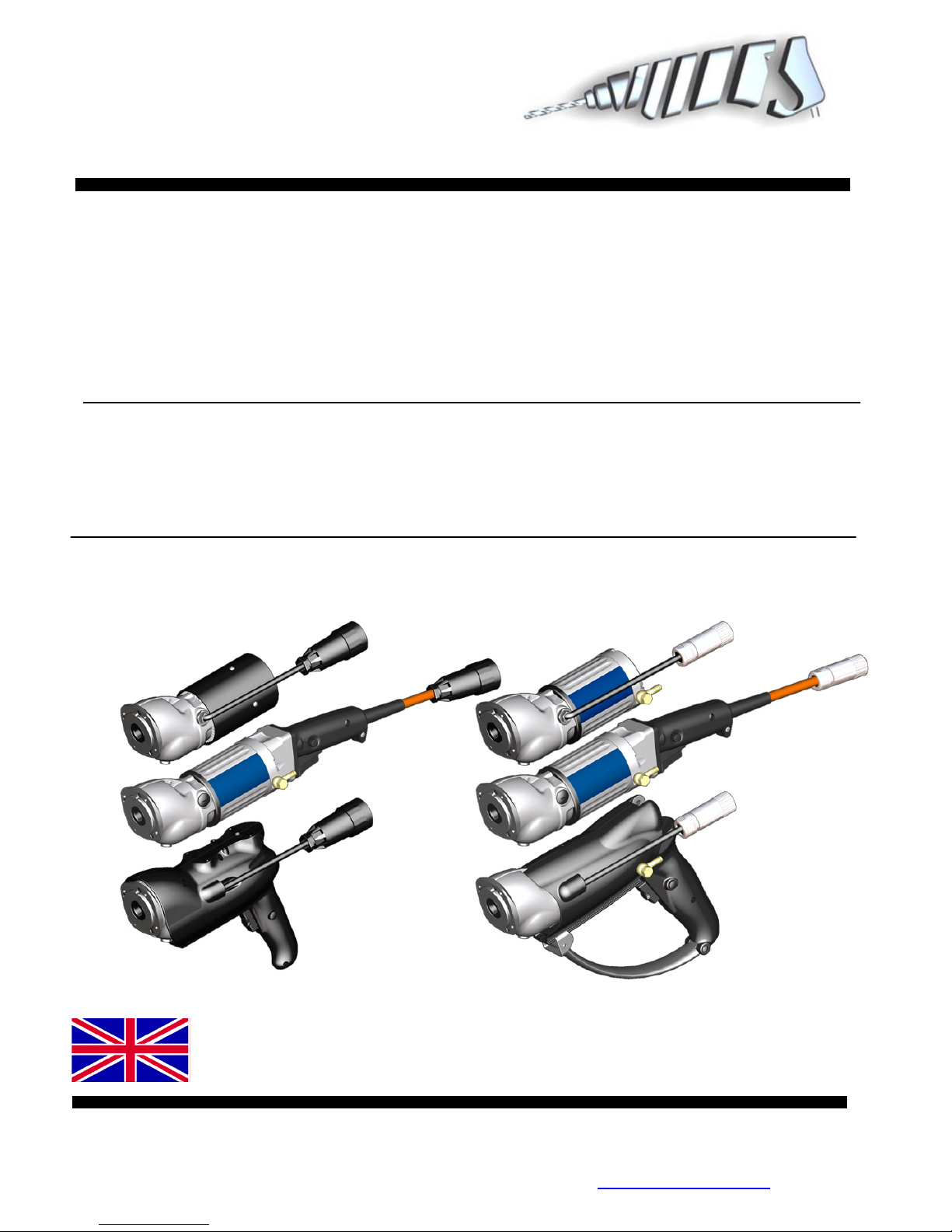

4.1.1 Beluga WX2, 230V 7

4.2.2 Beluga WX2 FH, 230V 7

4.1.3 Beluga WX2 B, 230V 7

4.1.4 Beluga WX 8, 400V 8

4.1.5 Beluga WX8 FH, 400V 8

4.1.6 Beluga WX8 B, 400V 8

4.2 Technical Data 9

4.2.1 Beluga WX2, WX2 FH, WX2 B, 230V 9

4.2.2 Beluga WX8, WX8 FH, WX8 B, 400V 9

4.3 Noise emissions and vibrations [EN 50144] WX2, WX2 FH 9

4.4 Noise emissions and vibrations n [EN 50144] WX2 B, WX8, WX8 FH, WX8 B 9

4.5 Operating temperatures 10

5.0 Commissioning 10

5.1 Mains connection 10

5.2 Control connecting sleeve - WX2, WX8 10

5.3 Water connection 11

5.4 Bayonet catch 11

5.5 Handle adjustment - WX8 FH 12

5.6 Saw blades and core bits 12

6.0 Safety instructions 12

7.0 Maintenance and care 13

7.1 Daily care 13

7.2 After approx. 150 hours of use 13

7.3 Quarterly 13

8.0 Speed adjustment dependent on the cutting speed 13

9.0 Warranty 13

10.0 General safety instructions 14

11.0 Spare parts lists 16

11.1 Beluga WX2, 230V 16

11.2 Beluga WX2 FH, 230V 16

11.3 Beluga WX2 B, 230V 18

11.4 Beluga WX8, 400V 18

11.5 Beluga WX8 FH, 400V 20

11.6 Beluga WX8 B, 400V 22

11.7 Motor, compl. WX2, WX2 FH, 230V 24

11.8 Motor, compl. WX8, WX8 FH, 400V 26

11.9 Motor, compl. WX2 B, 230V 28

11.10 Motor, compl. WX8 B, 400V 30

11.11 Gear compl. WX2, WX8 32

11.12 Gear compl. WX2FH, WX8B 34