Contents

2

In order to make it very clear which Instructions for Use is to be

used with each Vapor, the serial number of the Vapor assigned

is specified on the back of these Instructions for Use.

Instructions for Use without such a number are issued purely

for information purposes and not for actual use with a Vapor.

The serial number is specified on the nameplate of the Vapor.

Contents

For Your Safety and that of Your Patients ........................... 3

Intended Use ................................................................................. 4

Registered trademarks ................................................................. 4

Method of Operation .................................................................. 5

Control dial ..................................................................................... 5

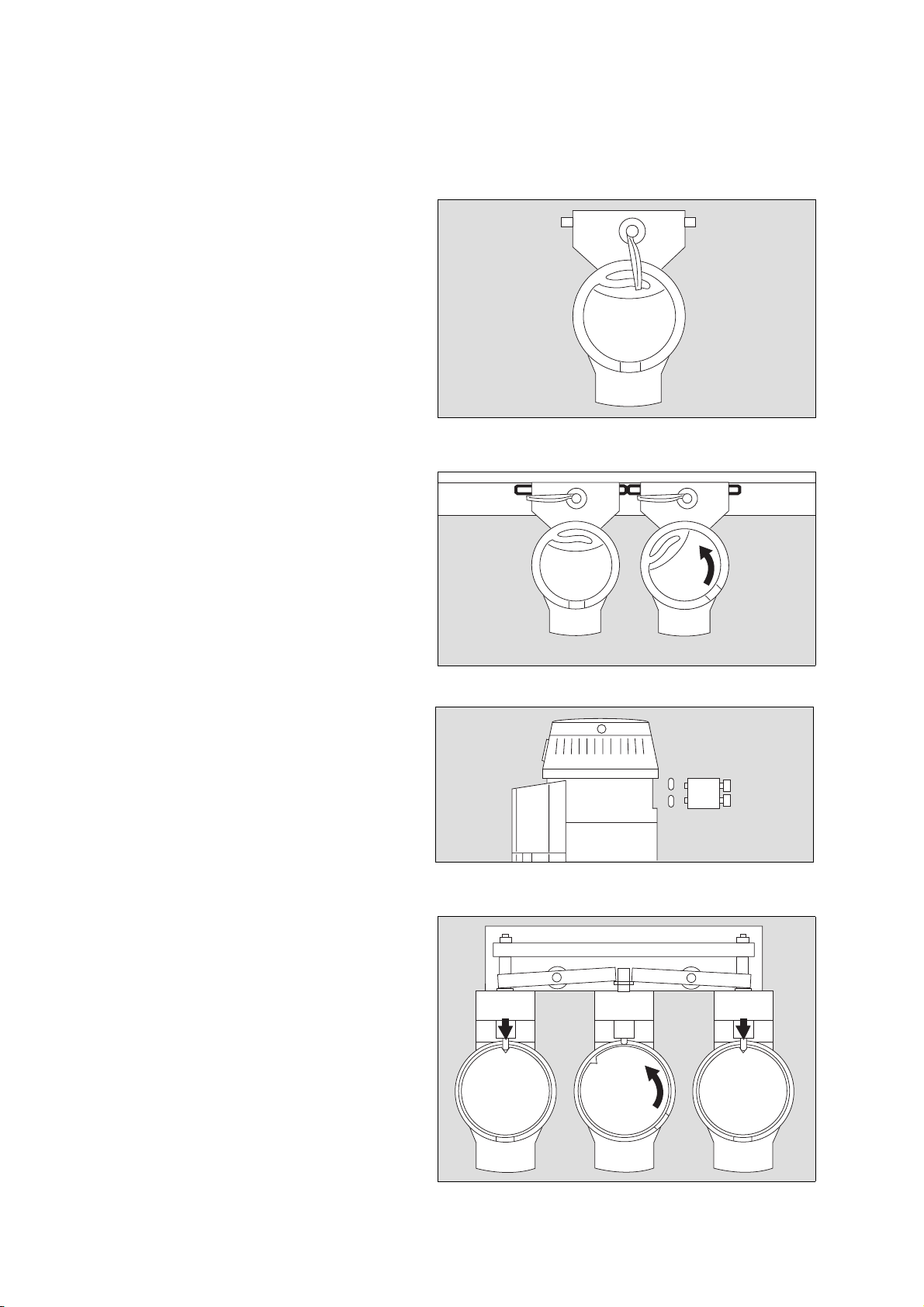

Connecting and Interlock systems ............................................ 6

Filling systems ................................................................................ 9

Preparation .................................................................................. 11

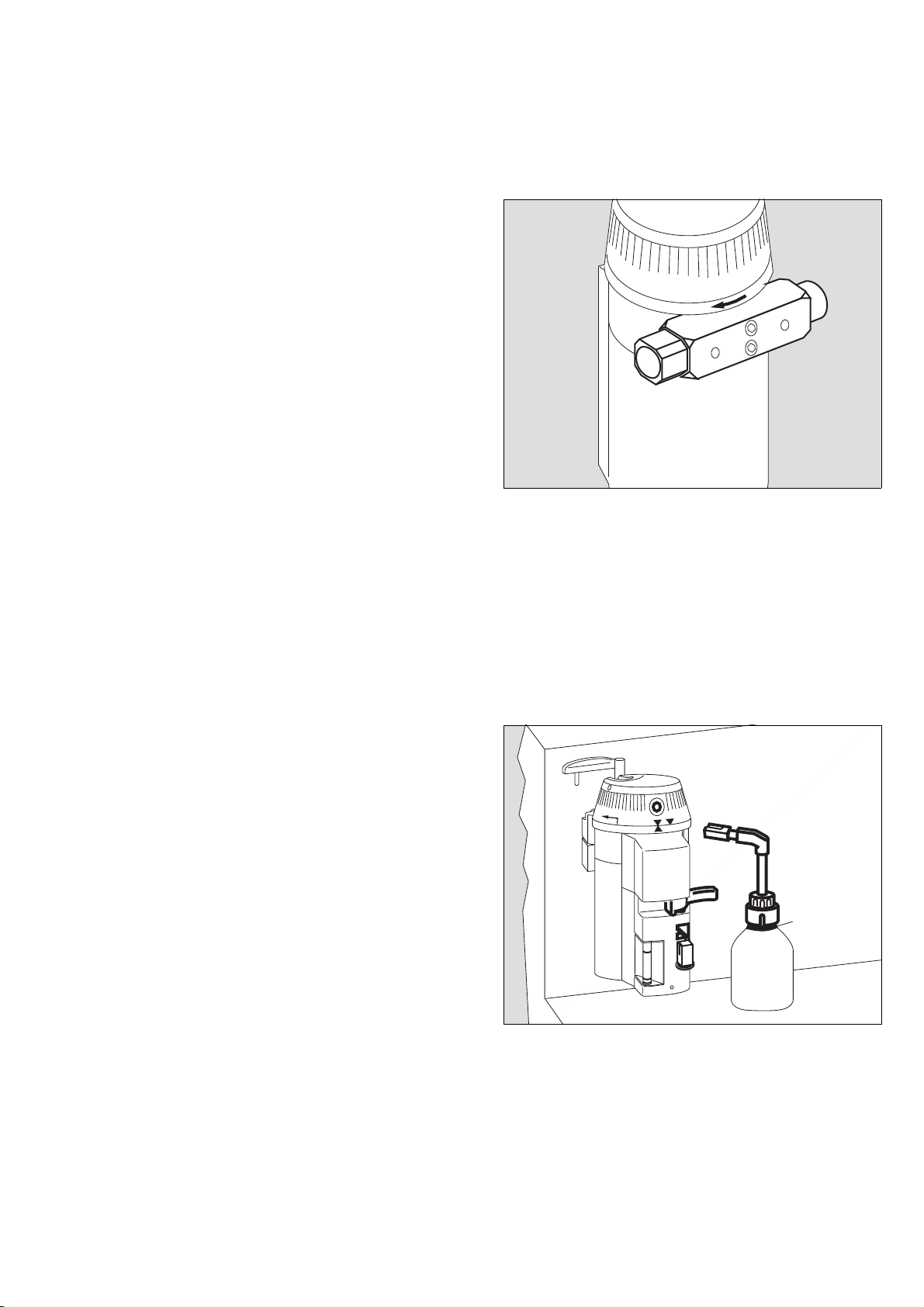

Fitting connectors ....................................................................... 11

Before using for the first time ................................................... 12

Filling Vapor .................................................................................13

Vapor with keyed filling system .......................................... 14

Vapor with Dräger Fill filling system.................................. 17

Vapor with Quik Fil filling system....................................... 19

Vapor with filling spout ........................................................ 21

Connecting Vapor .......................................................................22

Vapor with plug-in adapter .................................................. 22

Vapor with conical connectors without

Interlock system .................................................................... 23

Operation .....................................................................................24

Checklist – checks before each use ....................................... 24

Adjusting concentration of anaesthetic agent ......................26

Changing anaesthetic agent .....................................................26

Ending administration of anaesthetic agent ..........................27

End of use .....................................................................................27

Disconnecting Vapor ..................................................................28

Plug-in connector.................................................................. 28

For Auto Exclusion plug-in connector............................... 28

For conical connectors........................................................ 29

Permanent connection......................................................... 29

Transport when filled ..................................................................29

Fault – Cause – Remedy .........................................................30

Care ...............................................................................................35

Cleaning ........................................................................................35

Disinfecting ...................................................................................35

Checking Readiness for Operation ...................................... 36

Checking concentration ............................................................ 39

Shut-down .................................................................................... 41

Draining Vapor ............................................................................. 41

Vapor with keyed filling system.......................................... 41

Vapor with Dräger Fill filling system ................................. 42

Vapor with Quik Fil filling system ...................................... 43

Vapor with filling spout ........................................................ 45

Blowing off Vapor ........................................................................ 46

Storage ..........................................................................................46

Despatch .......................................................................................46

Return, disposal ........................................................................... 46

Maintenance Intervals .............................................................. 47

Inspection and service ............................................................... 47

Technical Data ............................................................................48

What's What ................................................................................. 51

Description ..................................................................................52

Operating principle .....................................................................52

Calibration ....................................................................................53

Influence of temperature ........................................................... 54

Influence of flow .......................................................................... 55

Influence of gas composition ................................................... 56

Influence of atmospheric pressure .......................................... 57

Influence of positive/negative pressure ................................. 57

Influence of fluctuations in pressure ....................................... 58

Influence of running time ...........................................................59

Order List .....................................................................................60

Abbreviations and Symbols .................................................... 61

Index ..............................................................................................62

Quality Inspection Certificate ................................................ 65