Mach LED 150F / 150 / 150FP

59320002 Edition 12 08.08.2018 / Bak We page 2/26

List of contents

1. Safety instructions.................................................................................... page 4

2. Brief description of the light MACH LED 150F / 150 / 150FP................... page 8

3. Operating the light Mach LED 150F / 150 / 150FP...................................page 8

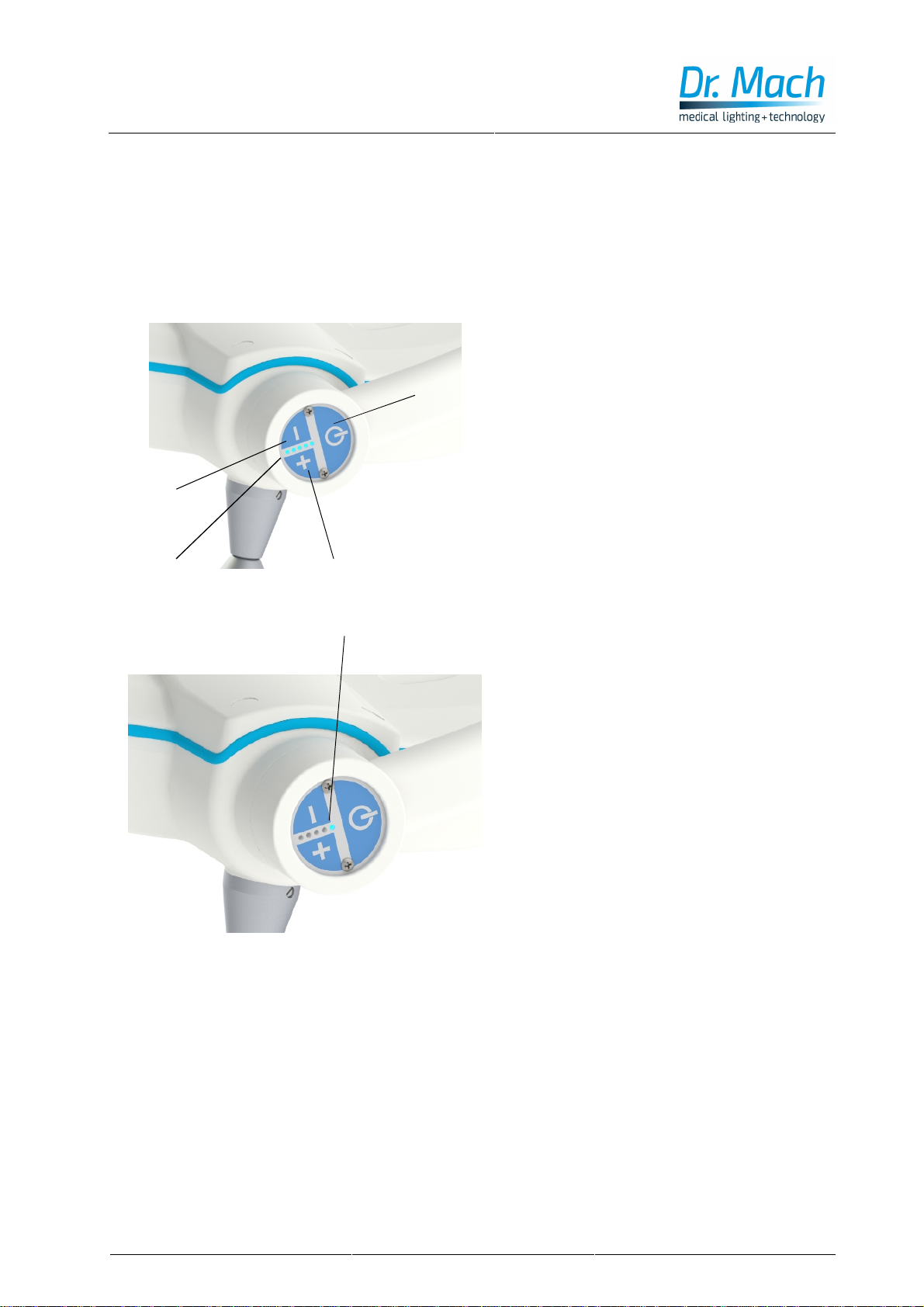

3.1 ON/OFF switch .................................................................................. page 8

3.2 Light intensity control......................................................................... page 8

3.3 Endo –Light (Mach LED 150 / 150F/150FP 4500 Kelvin only).......... page 8

3.3 Focusing (Mach LED 150F / 150FP only).......................................... page 9

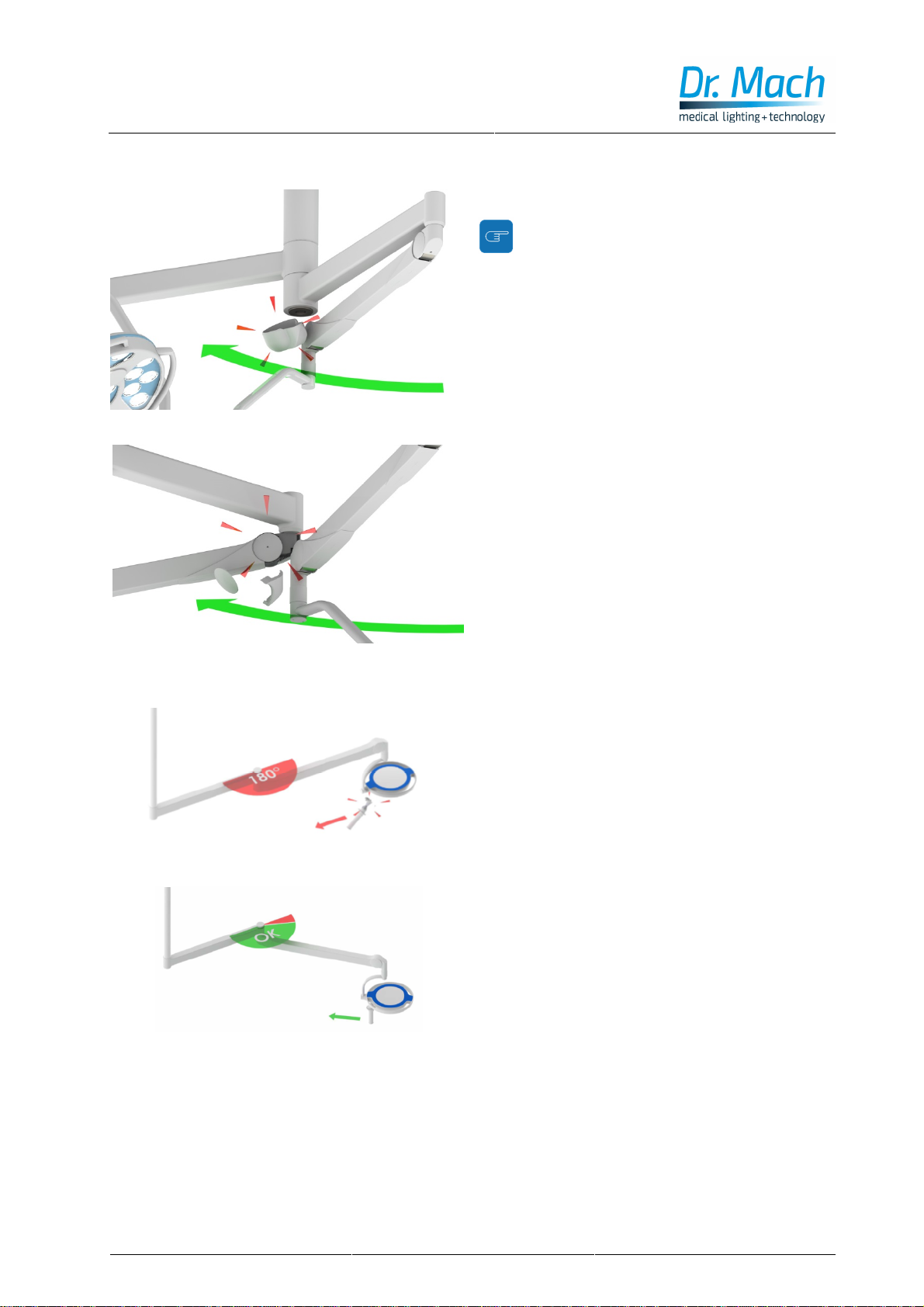

3.4 Positioning ......................................................................................... page 9

3.5 Danger of collision while positioning the lights...................................page 10

3.6 Addition to positioning the lamp......................................................... page 10

4. Cleaning................................................................................................... page 11

4.1 Sterilisable handle..............................................................................page 11

4.2 Lamp head, lens and protective disk.................................................. page 13

5. Initial operation and Maintenance ............................................................ page 14

5.1 Activity at initial operation and maintenance work.............................. page 14

6. Troubleshooting .......................................................................................page 15

7. Data ......................................................................................................... page 16

7.1 Technical data.................................................................................... page 16

7.2 Electrical data .................................................................................... page 17

7.3 Information regarding the electrical installation.................................. page 17

7.4 Weights.............................................................................................. page 17

7.5 Environmental conditions...................................................................page 18

7.6 General remarks................................................................................ page 19

8. CE-mark................................................................................................... page 19

9. Disposal ................................................................................................... page 19

10. Wiring diagram.......................................................................................page 20

11. Electromagnetic compatibility.................................................................page 21