5

1TTS900001M0902

Table of content

1. Introduction .........................................................................................................................6

1.1 Consequences in the Event of on Non-compliance......................................................6

2. Switchboard ........................................................................................................................7

2.1 Technical Data...........................................................................................................7

2.2 Switchboard Basic Structure ......................................................................................8

2.2.1 Typical Side Section...................................................................................................8

2.2.2 Busbars ....................................................................................................................9

2.2.3 Distribution bars ........................................................................................................9

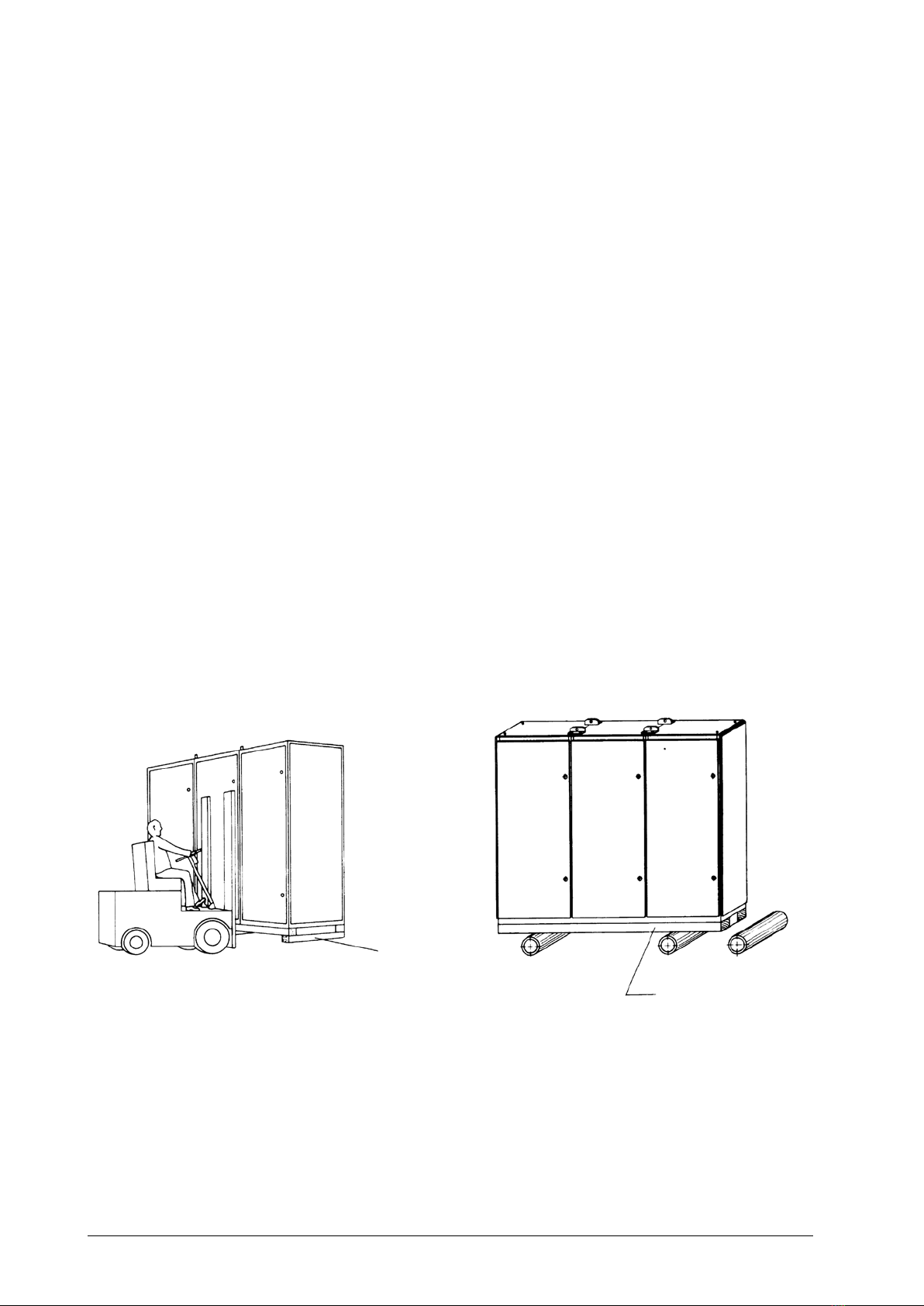

3. Packing and Transportation................................................................................................10

3.1 General ...................................................................................................................10

3.2 Packing...................................................................................................................10

3.3 Delivery and Unloading Operations ...........................................................................10

3.3.1 Unloading................................................................................................................10

3.3.2 Transportation by Means of Crane............................................................................11

3.3.3 Storage ................................................................................................................... 12

3.3.4 Spare Module Storage ............................................................................................. 12

4. Installation and Start up ..................................................................................................... 13

4.1 Check on Delivery....................................................................................................13

4.2 Installation...............................................................................................................13

4.2.1 Erection and Connection of the Cubicles...................................................................13

4.2.2 Additional Information for Switchgear Positioning ......................................................14

4.2.3 Fastening Methods to Foundation.............................................................................15

4.3 Cable and Bar Connection ....................................................................................... 16

4.3.1 Protective Conductor Connection.............................................................................16

4.3.2 Protection Degree....................................................................................................17

4.4 Final Preparations .................................................................................................... 17

4.5 Check Operations....................................................................................................17

4.6 Start up...................................................................................................................18

5. Maintenance......................................................................................................................20

5.1 General ...................................................................................................................20

5.2 Maintenance Intervals .............................................................................................. 20

5.3 Maintenance Program..............................................................................................21

5.4 Repair Operations for Possible Malfunctions..............................................................23

5.5 Health and Safety .................................................................................................... 24

6. List of the Switchboard Main Equipment .............................................................................24

Appendix A: Bolts and nuts, and tightening torque

This document and the related enclosures, are property of ABB Sace S.p.A. It is forbidden to copy or

disclose them totally or partially, without ABB Sace S.p.A. approval.