© 2018 Dragonfly

Fixed Projection Screen Manual

181004-0945

Step 6A

Step 6B-C

Fabric

Edge

Step 4

C (for UAW screen only)

D-E

10 4

7

5

212

11 9

8

1

3

6

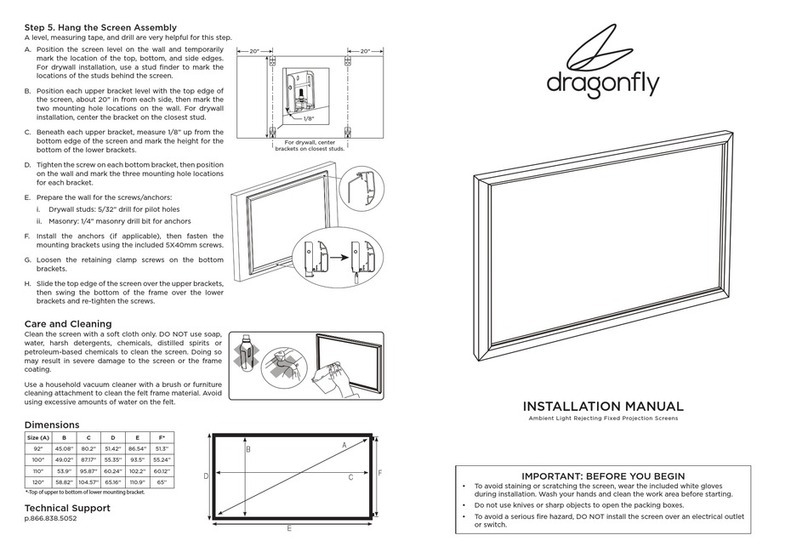

Step 5

Step 4. Prepare the Screen Material

A. Lay the protective sheet out on the work surface, and

clean the surface and work area to avoid staining the

screen material.

B. Put on the supplied gloves before handling the screen

material.

D. Roll the screen material out onto the protective sheet,

then lay the frame down onto the material, ensuring the

corners of the frame and fabric are properly aligned as

shown in Step 4.

E. Insert frame rods into the edges of the screen as shown

in step 4.

C. Fit the frame into the black scrim cloth pockets from 4

corners. Adjust the position until the pockets are fixed

tight and the black cloth flat. (For UAW screen only)

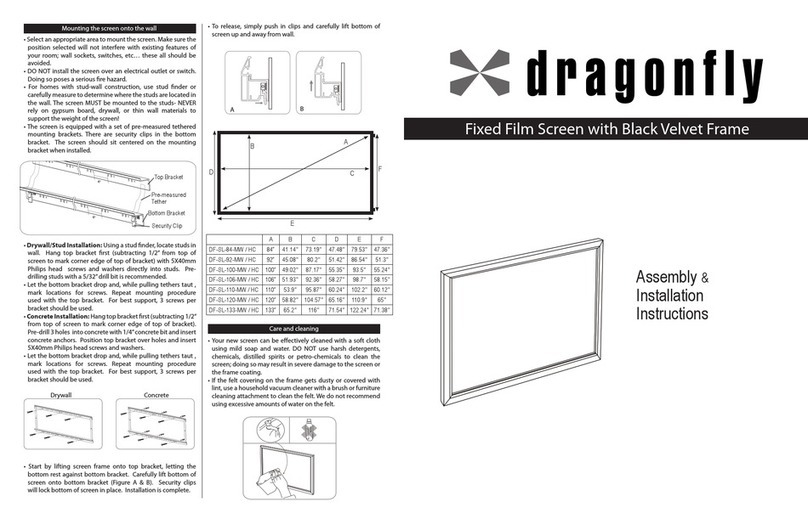

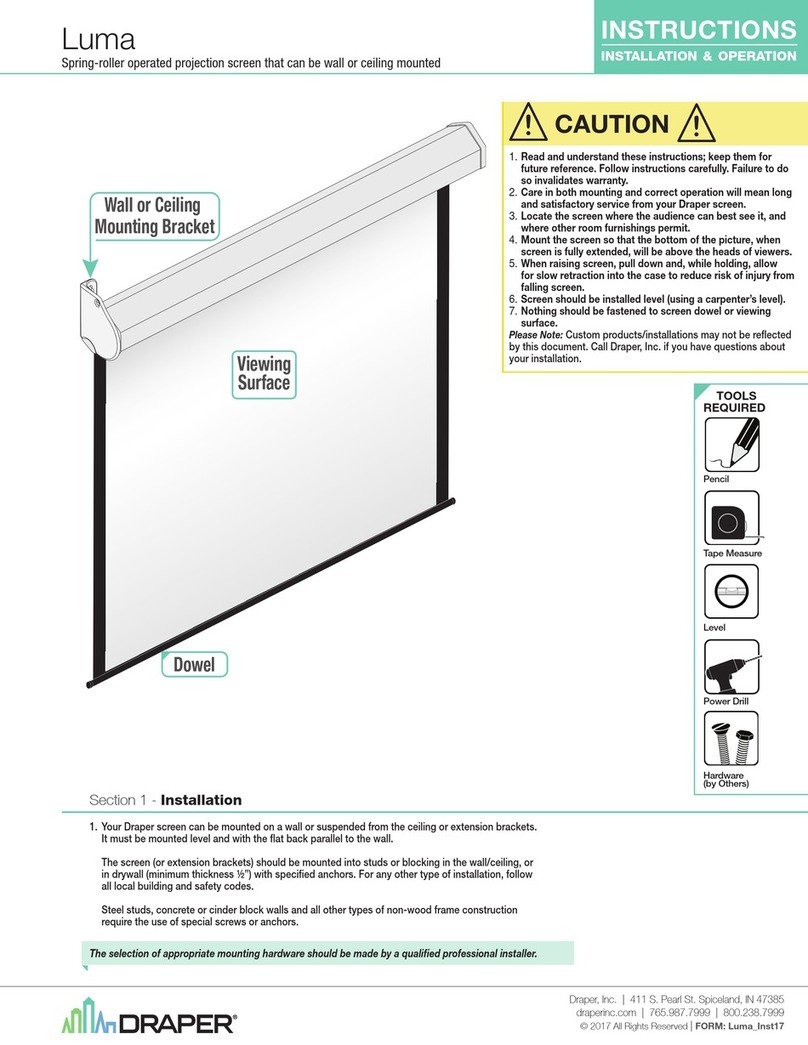

Step 5. Attach the Screen Material to the Frame

A. Align the springs to the holes in the screen fabric.

B. Using the spring tool, attach the springs to the screen

material, following the numbering in the image to the

right, ensuring screen and frame stay aligned with

corners. Once the corners are connected, work around

the screen attaching the remaining springs.

C. Ensure all springs are installed straight and

perpendicular to the screen. Any springs installed at

an angle may cause ripples in the screen material.

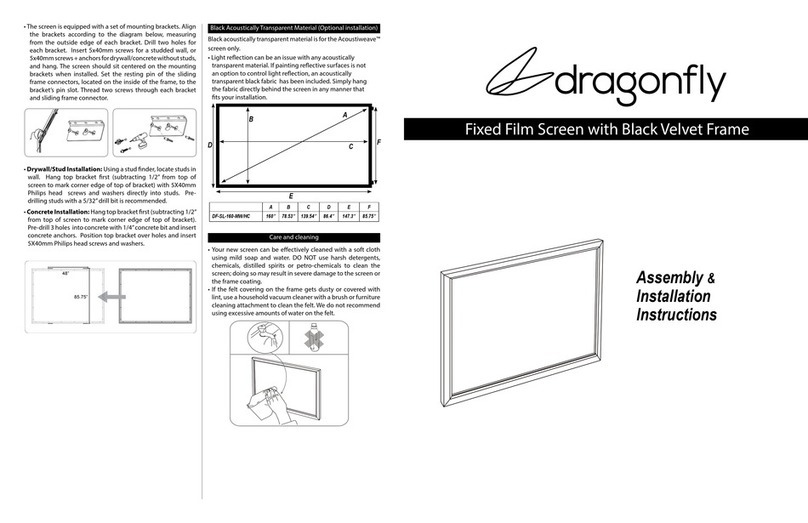

Step 6. Install Brackets and Frame Bezels

A. With the film screen still laying face down, lay the thin

bezel caps on to the respective horizontal and vertical

edges of the screen. The aluminum side should be facing

up with fabric edges facing out. Refer to Image 6A.

i. The tracks on theback of thethinbezel caps align for

atight fit in each of the corners. Refer to image6B.

B. Once the thin bezel frames are in place and aligned,

install the thin bezel frame brackets.

i. 10 total brackets will be used to tighten all 4 thin

bezel caps in place. 2 brackets for each of the

vertical frames and 3 brackets for each of the

horizontal frames.

C. Hook curved end of the thin bezel bracket to the

outermost track of the thin bezel cap and align it with

a sliding nut. Use the M5x6mm screws to tighten.

Note: There are 4 additional sliding nuts on the horizontal

frames, 2 on each side. These sliding nuts are used to

install the wall brackets.

Step 3. Assemble the Frame

A. Slide the short frame sections into the long frame sections.

B. Insert the 8 frame corner screws into all 4 corners of the

frame and loosely tighten to hold the frame together.

C. Hand-tighten all four screws, ensure the corners are

square, then tighten the screws completely.

D. Lift up and set aside to prepare screen material for assembly.

Step 3

B

x32

C

Hold in center

Smooth material

towards corners

Installation Tips

Take care to pull material evenly before installing the

bezels.

If waves/wrinkles are present, it may be necessary to

remove the bezel and pull the material tightly before

reattaching the bezel.

Refer to the image to the right for the best practice for

smoothing wrinkles that may be present.

© 2018 Dragonfly

Fixed Projection Screen Manual

181004-0945

Step 1. Unpack the Screen

Lay out all parts on a clean, flat surface. To prevent damage, do not unpack the screen material at this time.

NOTE: Quantities below may be greater than needed for assembly.

Package Contents

Thin Bezel Frame

Brackets (10)

M5x6mm Corner

Screws (46)

Sliding Nuts [installed]

(14)

Gloves (2 Pair)

M5x40mm Phillips

Head Screws (6)

Concrete

Anchors (6)

Screen

Material (1)

Screen Frame & Frame Bezels

(2 short, 2 long each)

Tension Rods

(2 short, 2 long each)

Corner Brackets

(8)

Spring Tool (2)

Material Springs

[installed]

*Extra Springs included in the

hardware pack

Protective Sheet

(1)

Black Scrim (1) (Only applied

for UAW screen product)

Step 2. Prepare Frame Sections for Assembly

A. Retention springs are pre-assembled. Please confirm

based on quantity noted on frame label and in the

manual below for the short and long frame sections

and count all prior to install. Any extras needed are

in the hardware pack.

Qty. of Pre-assembly Springs

Screen Size 92 100 106 110 120

Each Long Side 12 12 14 14 14

Each Short Side 7 7 8 8 9

i. The hook on the spring must be on the groove

closest to the inside frame edge.

B. Sliding nuts are pre-installed into frames, 14 total. Sliding nuts are used to install the thin bezel caps, and

wall brackets. Please ensure all 14 sliding nuts are on the frames prior to installing and tightening the

corner brackets.

C. Install the corner brackets to the top and bottom slots of the short frame sections. All corner brackets are

the same size and interchangeable.

M5x8mm Mounting

Screws (3)

Mounting Brackets (2)

Magnets (2)

" " " " "