Copyright © 2008 Draper Inc. Form AeroLift50-150-220V_Inst08 Printed in U.S.A.

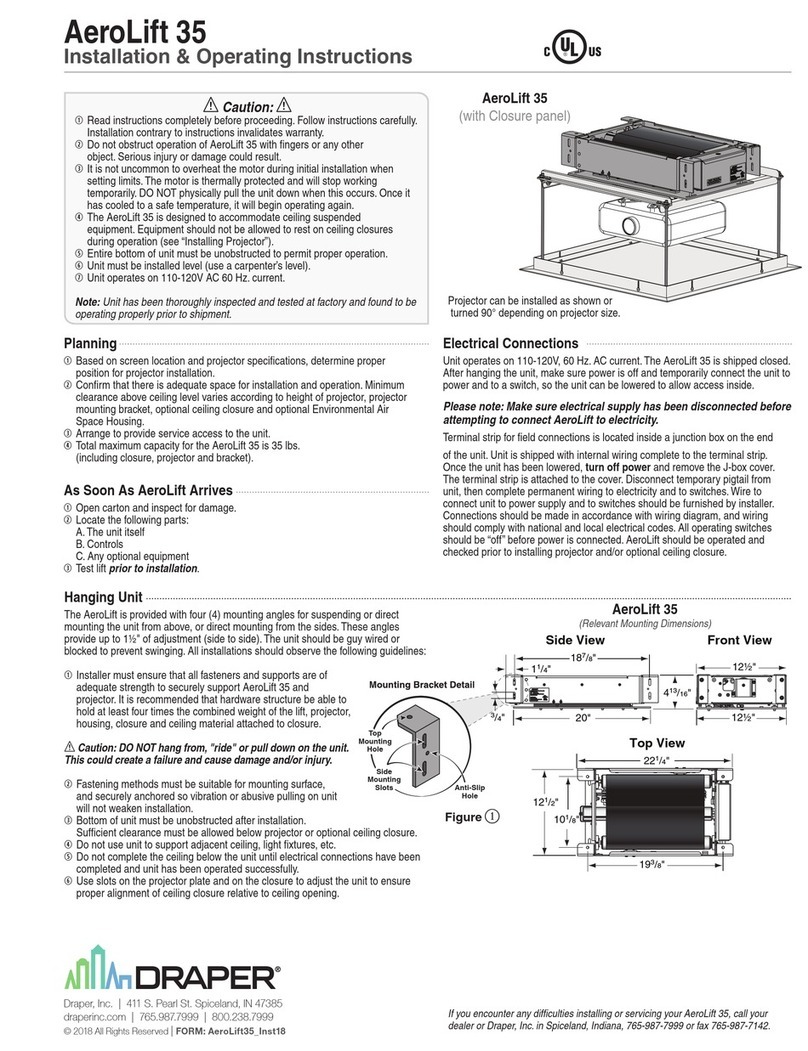

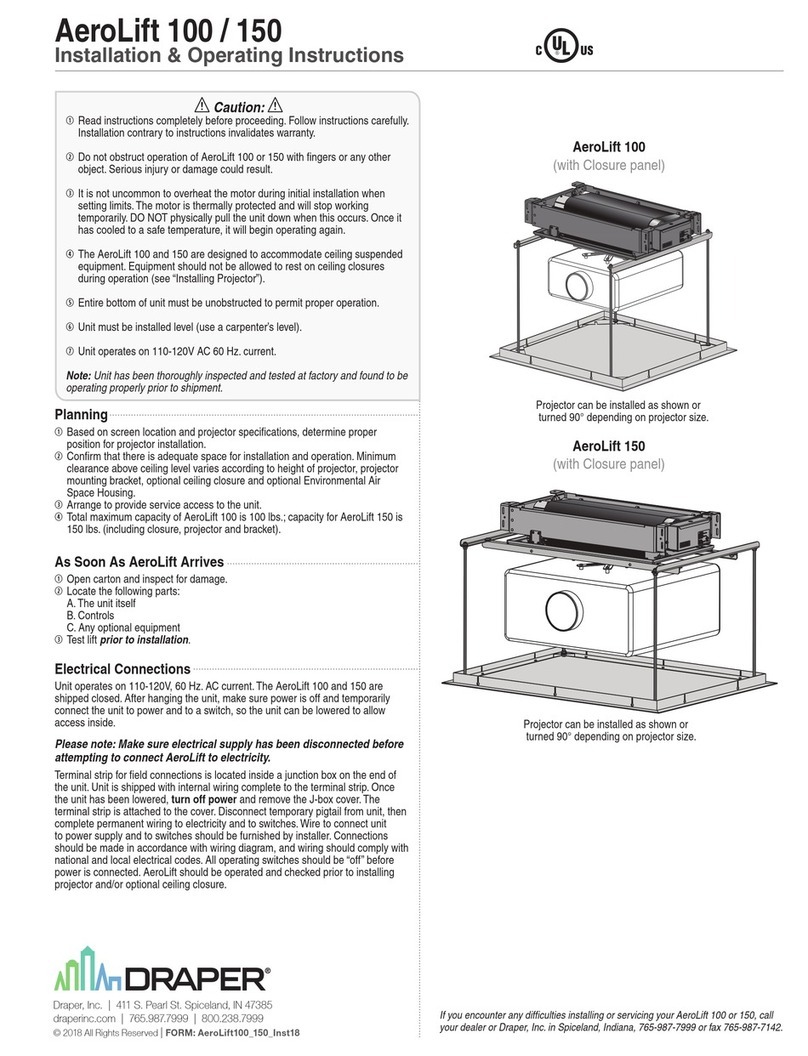

Planning

➀Based on screen location and projector specifications, determine proper

position for projector installation.

➁Confirm that there is adequate space for installation and operation. Minimum

clearance above ceiling level varies according to height of projector, projector

mounting bracket, optional ceiling closure and optional Environmental Air Space

Housing.

➂Arrange to provide service access to the unit.

➃Total maximum capacity of AeroLift 50 is 23 kg.; capacity for AeroLift 150 is 68

kg., including closure, projector and bracket.

As Soon As AeroLift Arrives

➀Open carton and inspect for damage.

➁Locate the following parts:

A. The unit itself

B. Controls

C. Any optional equipment

➂ Test lift prior to installation.

Installation/Operating Instructions

220V AeroLift 50/150 by Draper

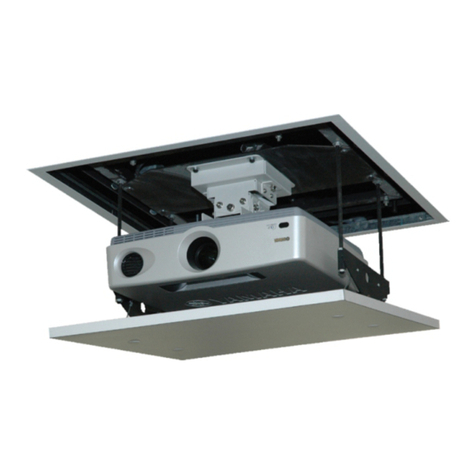

Hanging Unit

The AeroLift is provided with four (4) mounting angles for suspending or direct

mounting the unit from above, or direct mounting from the sides. These angles

provide up to 38 mm of adjustment (side to side). The unit should be guy wired

or blocked to prevent swinging. All installations should observe the following

guidelines:

➀Installer must ensure that all fasteners and supports are of adequate strength to

securely support AeroLift 50/150 and projector. It is recommended that

hardware structure be able to hold at least four times the combined weight of

the lift, projector, Environmental Air Space Housing, closure and ceiling material

attached to closure.

Caution: DO NOT hang from, "ride" or pull down on the unit. This could

create a failure and cause damage and/or injury.

➁Fastening methods must be suitable for mounting surface, and securely

anchored so vibration or abusive pulling on unit will not weaken installation.

➂Bottom of unit must be unobstructed after installation. Sufficient clearance

must be allowed below projector or optional ceiling closure.

➃Do not use unit to support adjacent ceiling, light fixtures, etc.

➄Do not complete the ceiling below unit until electrical connections have

been completed and unit has been operated successfully.

➅Use slots on the projector plate and on the closure to adjust the unit to

ensure proper alignment of ceiling closure relative to ceiling opening.

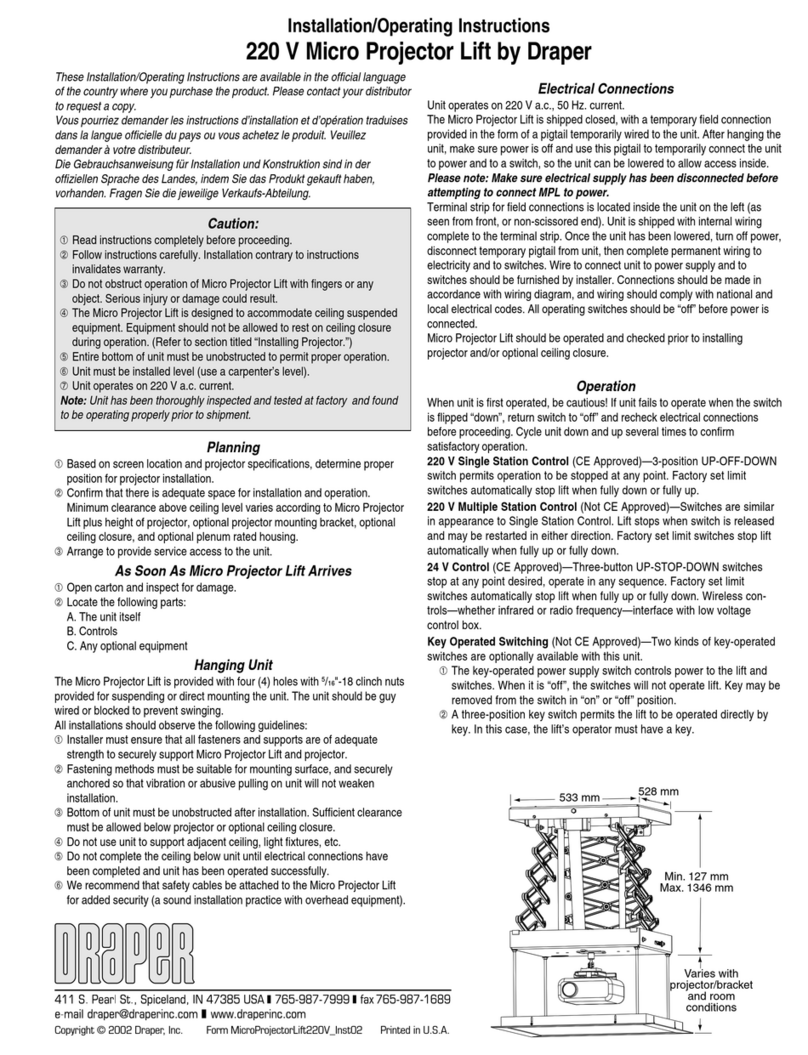

Electrical Connections

Unit operates on 220V AC current. The AeroLift 50 and 150 are shipped closed,

with a temporary field connection provided in the form of a pigtail temporarily wired

to the unit. After hanging the unit, make sure power is off and use this pigtail to

temporarily connect the unit to power and to a switch, so the unit can be lowered

to allow access inside.

Please note: Make sure electrical supply has been disconnected before

attempting to connect AeroLift to electricity.

Terminal strip for field connections is located inside a junction box on the end of

the unit. Unit is shipped with internal wiring complete to the terminal strip. Once

the unit has been lowered, turn off power and remove the J-box cover. The

terminal strip is attached to the cover. Disconnect temporary pigtail from unit, then

Caution:

➀Read instructions completely before proceeding. Follow instructions

carefully. Installation contrary to instructions invalidates warranty.

➁Do not obstruct operation of AeroLift 50/150 with fingers or any other

object. Serious injury or damage could result.

➂It is not uncommon to overheat the motor during initial installation when

setting limits. The motor is thermally protected and will stop working

temporarily. DO NOT physically pull the unit down when this occurs.

Once it has cooled to a safe temperature, it will begin operating again.

➃The AeroLift 50 and 150 are designed to accommodate ceiling sus-

pended equipment. Equipment should not be allowed to rest on ceiling

closures during operation (see “Installing Projector”).

➄Entire bottom of unit must be unobstructed to permit proper operation.

➅Unit must be installed level (use a carpenter’s level).

➆Unit operates on 220V AC current.

Note: Unit has been thoroughly inspected and tested at factory and found to be

operating properly prior to shipment.

complete permanent wiring to electricity and to switches. Wire to connect unit

to power supply and to switches should be furnished by installer. Connections

should be made in accordance with wiring diagram, and wiring should comply with

national and local electrical codes. All operating switches should be “off” before

power is connected. AeroLift should be operated and checked prior to installing

projector and/or optional ceiling closure.

Operation

When unit is first operated, be cautious! If unit fails to operate when the switch

is flipped “down”, return switch to “off” and recheck electrical connections

before proceeding. Cycle unit down and up several times to confirm satisfactory

operation.

220V Single Station Control (CE Approved)—3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory set limit switches automati-

cally stop lift when fully down or fully up.

220V Multiple Station Control (Not CE Approved)—Switches are similar in ap-

pearance to Single Station Control. Lift stops when switch is released and may be

restarted in either direction. Factory set limit switches stop lift automatically when

fully up or fully down.

24V Control (CE Approved)—Three-button UP-STOP-DOWN switches stop at any

point desired, operate in any sequence. Factory set limit switches automatically

stop lift when fully up or fully down. Wireless controls—whether infrared or radio

frequency—interface with low voltage control box.

RS232/Ethernet (CE Approved)—Serial communication and network

communication optionally available with wall switches, RF or IR remote.

Key Operated Switching (Not CE Approved)—Two kinds of key-operated

switches are optionally available with this unit. ➀ The key-operated power sup-

ply switch controls power to the lift and switches. When it is “off”, the switches will

not operate lift. Key may be removed from the switch in “on” or “off” position. ➁A

three-position key switch permits the lift to be operated directly by key. In this case,

the lift’s operator must have a key.

If you encounter any difficulties installing or servicing your AeroLift 50 or 150, call

your dealer or Draper, Inc. in Spiceland, Indiana, 765-987-7999 or fax 765-987-7142.

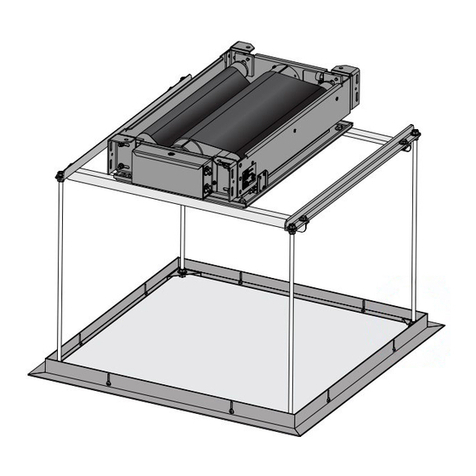

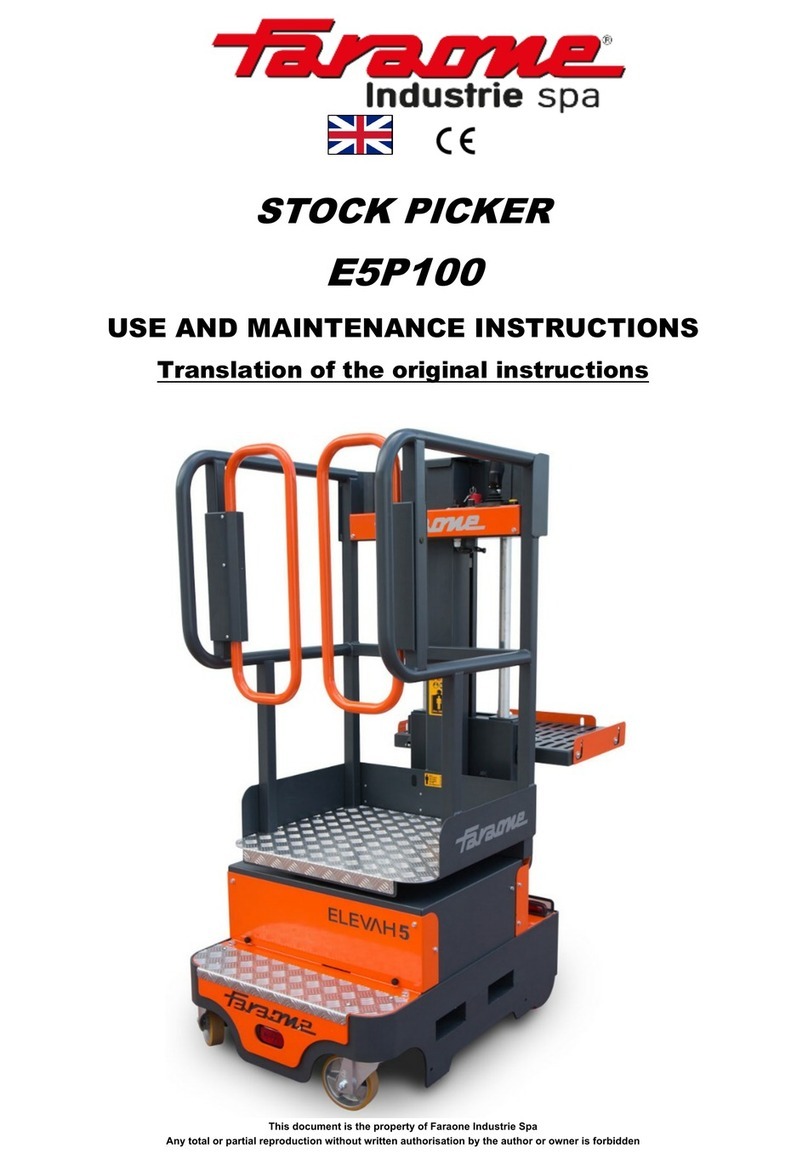

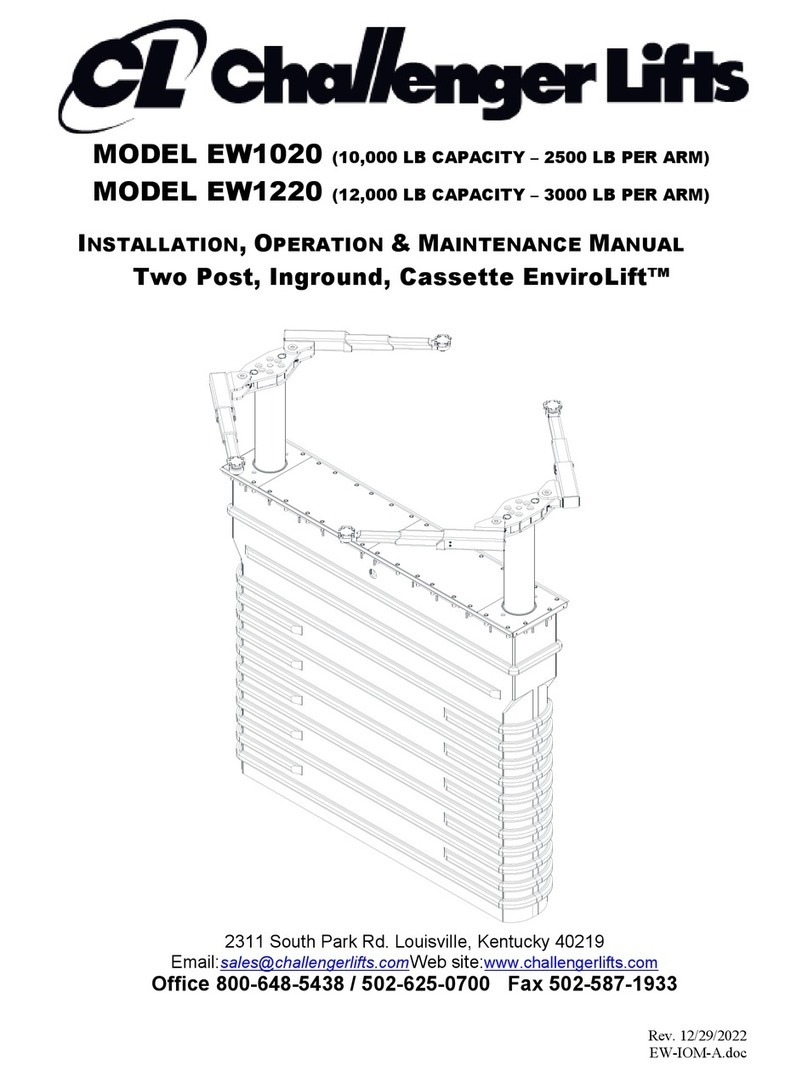

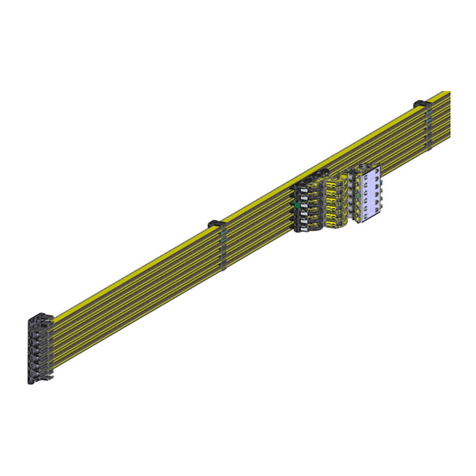

AeroLift Mounting Hole Dimensions

Please Note: As weight is applied to the AeroLift, the projector plate may

shift slightly. If this occurs, use setscrews on bottom of fabric roller brackets

to compensate for shift and level projector plate (see page 3).

C

D

E

A

B

F

Top ViewSide View

Lift A* B* C* D* E* F

AeroLift 50 718 381-343 273-311 673 679 159-972

AeroLift 150 794 365-454 295-333 749 756 159-972

* Measurements shown in millimeters.

Testing the Safety Limit Switches

The AeroLift 50 is equipped with a Safety Limit Switch and the 150 is equipped

with two Safety Limit Switches (see "AeroLift—Limit Switch Adjustment (Bottom

View)" diagram on page 3). These switches may be damaged during shipping or

by rough handling on the job site. Once the AeroLift has been installed in the ceil-

ing, but before the projector and closure are attached, the Safety Limits must be

tested. Use a screwdriver or other tool to press and hold the switch. While holding

down the switch, have someone operate the unit. If the unit works while the

switch is depressed, the limit switch is broken and must be replaced. Operat-

ing the unit without a functioning Safety Limit Switch could cause the unit's motor

to continue operating after the lift is closed, leading to a failure and the possibility

of damage or injury. Make sure to test BOTH switches on the 150.