Copyright © 2002 Draper, Inc. Form MicroProjectorLift220V_Inst02 Printed in U.S.A.

Planning

➀Based on screen location and projector specifications, determine proper

position for projector installation.

➁Confirm that there is adequate space for installation and operation.

Minimum clearance above ceiling level varies according to Micro Projector

Lift plus height of projector, optional projector mounting bracket, optional

ceiling closure, and optional plenum rated housing.

➂Arrange to provide service access to the unit.

As Soon As Micro Projector Lift Arrives

➀Open carton and inspect for damage.

➁Locate the following parts:

A. The unit itself

B. Controls

C. Any optional equipment

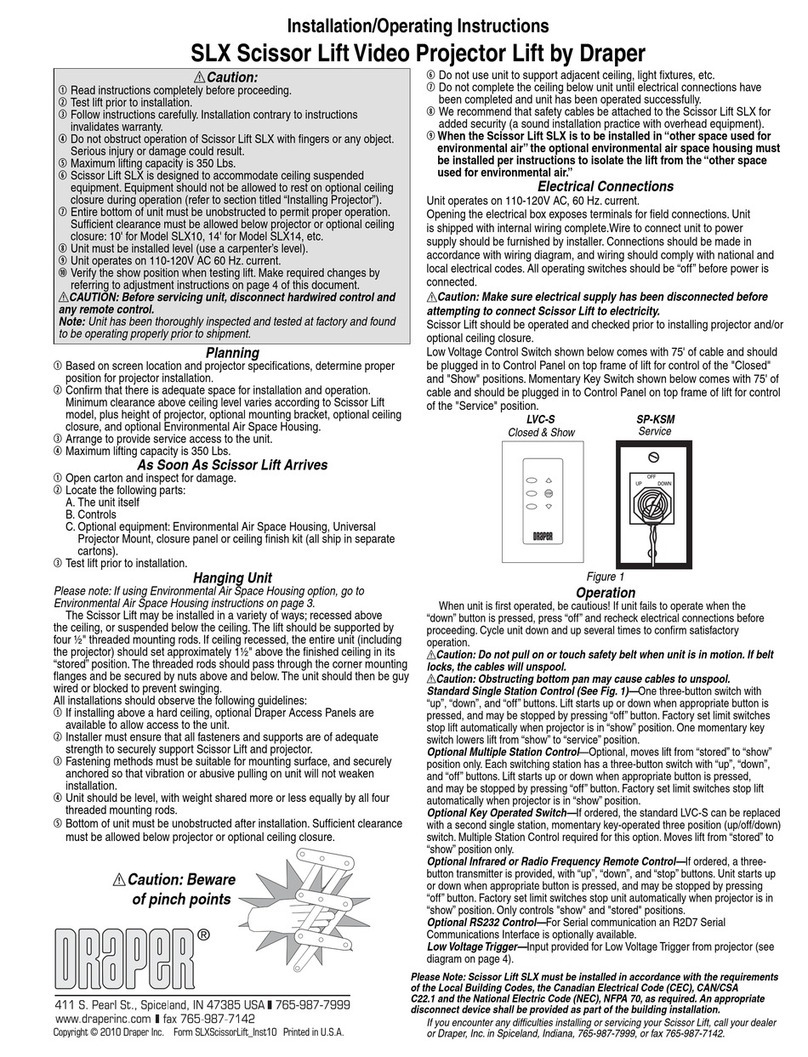

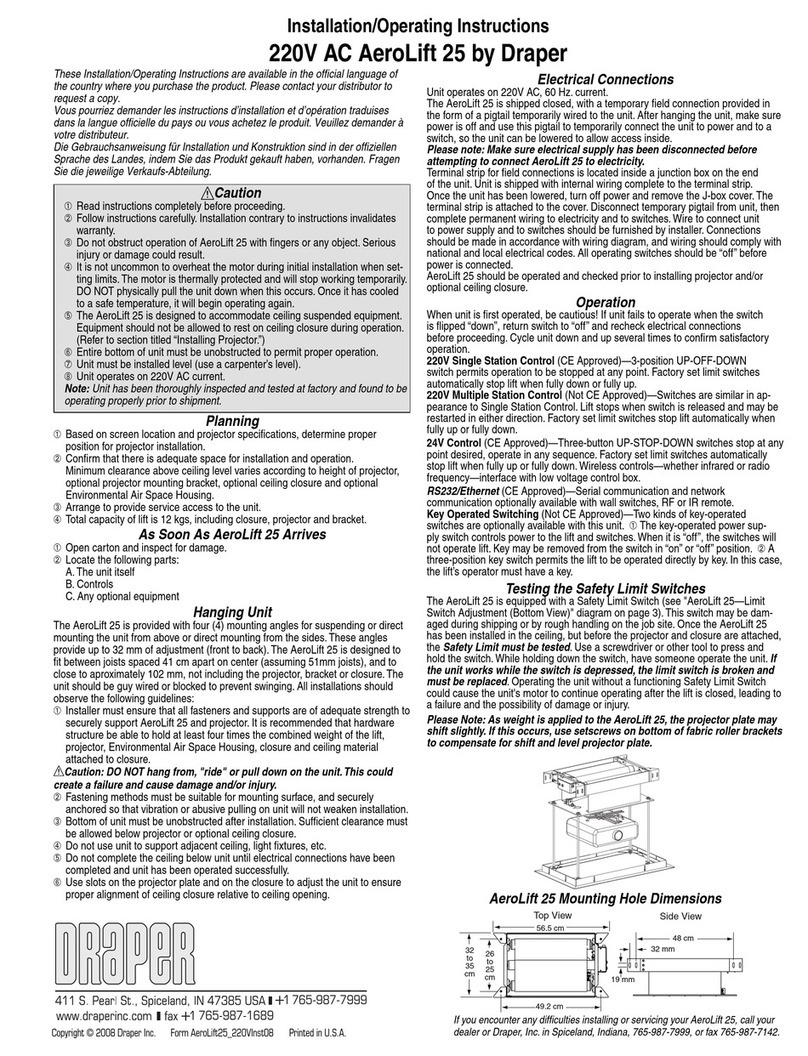

Installation/Operating Instructions

220 V Micro Projector Lift by Draper

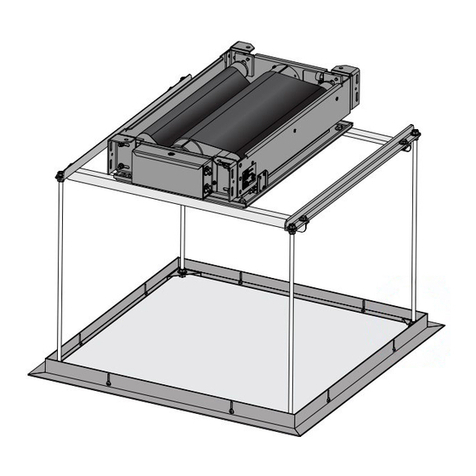

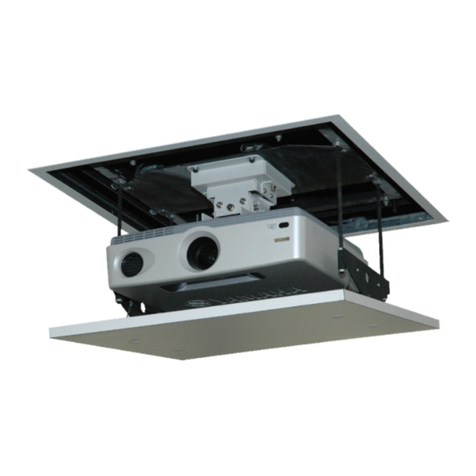

Hanging Unit

The Micro Projector Lift is provided with four (4) holes with

5

/

16

"-18 clinch nuts

provided for suspending or direct mounting the unit. The unit should be guy

wired or blocked to prevent swinging.

All installations should observe the following guidelines:

➀Installer must ensure that all fasteners and supports are of adequate

strength to securely support Micro Projector Lift and projector.

➁Fastening methods must be suitable for mounting surface, and securely

anchored so that vibration or abusive pulling on unit will not weaken

installation.

➂Bottom of unit must be unobstructed after installation. Sufficient clearance

must be allowed below projector or optional ceiling closure.

➃Do not use unit to support adjacent ceiling, light fixtures, etc.

➄Do not complete the ceiling below unit until electrical connections have

been completed and unit has been operated successfully.

➅We recommend that safety cables be attached to the Micro Projector Lift

for added security (a sound installation practice with overhead equipment).

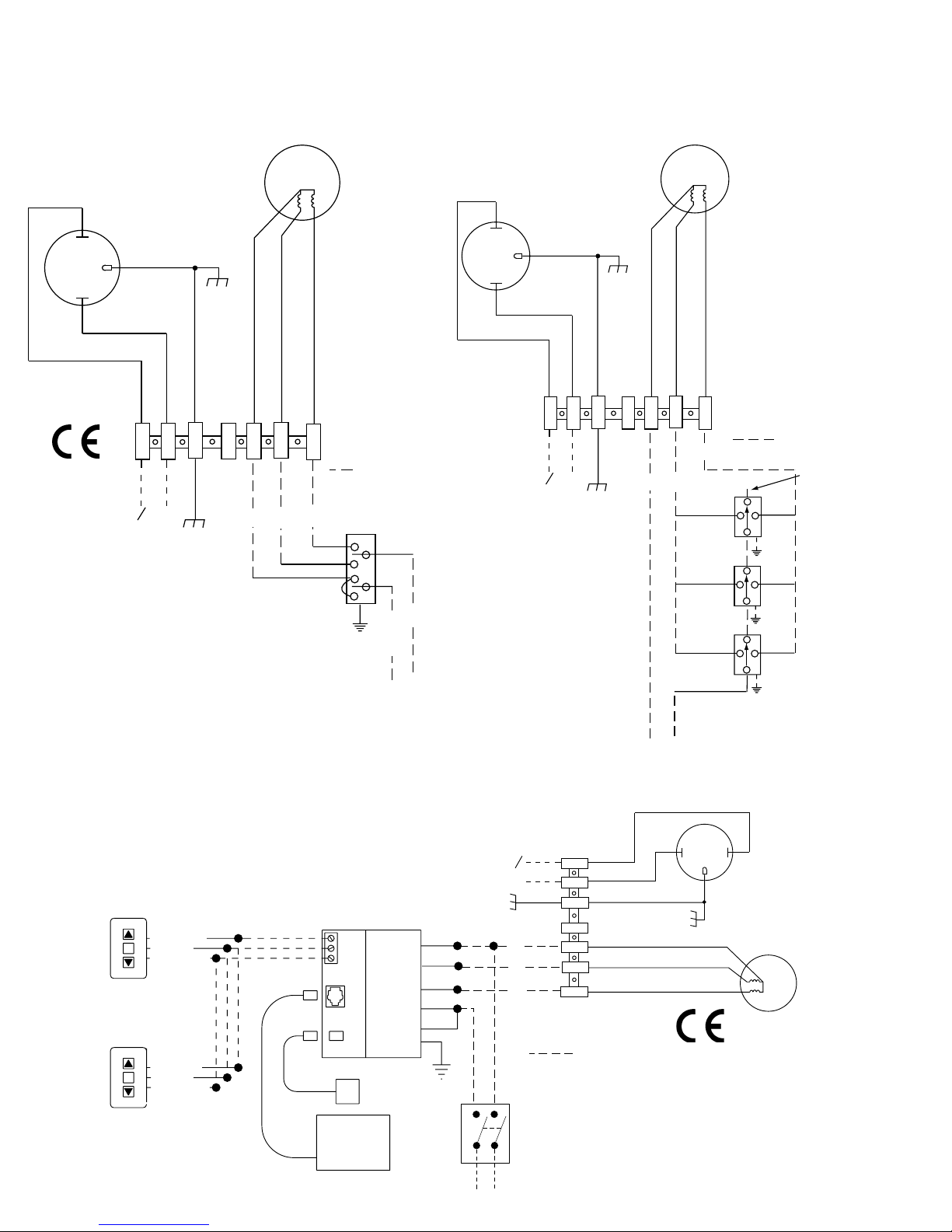

Electrical Connections

Unit operates on 220 V a.c., 50 Hz. current.

The Micro Projector Lift is shipped closed, with a temporary field connection

provided in the form of a pigtail temporarily wired to the unit. After hanging the

unit, make sure power is off and use this pigtail to temporarily connect the unit

to power and to a switch, so the unit can be lowered to allow access inside.

Please note: Make sure electrical supply has been disconnected before

attempting to connect MPL to power.

Terminal strip for field connections is located inside the unit on the left (as

seen from front, or non-scissored end). Unit is shipped with internal wiring

complete to the terminal strip. Once the unit has been lowered, turn off power,

disconnect temporary pigtail from unit, then complete permanent wiring to

electricity and to switches. Wire to connect unit to power supply and to

switches should be furnished by installer. Connections should be made in

accordance with wiring diagram, and wiring should comply with national and

local electrical codes. All operating switches should be “off” before power is

connected.

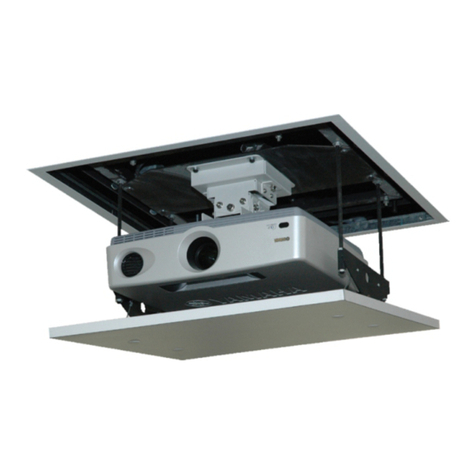

Micro Projector Lift should be operated and checked prior to installing

projector and/or optional ceiling closure.

Caution:

➀Read instructions completely before proceeding.

➁Follow instructions carefully. Installation contrary to instructions

invalidates warranty.

➂Do not obstruct operation of Micro Projector Lift with fingers or any

object. Serious injury or damage could result.

➃The Micro Projector Lift is designed to accommodate ceiling suspended

equipment. Equipment should not be allowed to rest on ceiling closure

during operation. (Refer to section titled “Installing Projector.”)

➄Entire bottom of unit must be unobstructed to permit proper operation.

➅Unit must be installed level (use a carpenter’s level).

➆Unit operates on 220 V a.c. current.

Note:

Unit has been thoroughly inspected and tested at factory and found

to be operating properly prior to shipment.

Operation

When unit is first operated, be cautious! If unit fails to operate when the switch

is flipped “down”, return switch to “off” and recheck electrical connections

before proceeding. Cycle unit down and up several times to confirm

satisfactory operation.

220 V Single Station Control (CE Approved)—3-position UP-OFF-DOWN

switch permits operation to be stopped at any point. Factory set limit

switches automatically stop lift when fully down or fully up.

220 V Multiple Station Control (Not CE Approved)—Switches are similar

in appearance to Single Station Control. Lift stops when switch is released

and may be restarted in either direction. Factory set limit switches stop lift

automatically when fully up or fully down.

24 V Control (CE Approved)—Three-button UP-STOP-DOWN switches

stop at any point desired, operate in any sequence. Factory set limit

switches automatically stop lift when fully up or fully down. Wireless con-

trols—whether infrared or radio frequency—interface with low voltage

control box.

Key Operated Switching (Not CE Approved)—Two kinds of key-operated

switches are optionally available with this unit.

➀The key-operated power supply switch controls power to the lift and

switches. When it is “off”, the switches will not operate lift. Key may be

removed from the switch in “on” or “off” position.

➁A three-position key switch permits the lift to be operated directly by

key. In this case, the lift’s operator must have a key.

These Installation/Operating Instructions are available in the official language

of the country where you purchase the product. Please contact your distributor

to request a copy.

Vous pourriez demander les instructions d’installation et d’opération traduises

dans la langue officielle du pays ou vous achetez le produit. Veuillez

demander à votre distributeur.

Die Gebrauchsanweisung für Installation und Konstruktion sind in der

offiziellen Sprache des Landes, indem Sie das Produkt gekauft haben,

vorhanden. Fragen Sie die jeweilige Verkaufs-Abteilung.

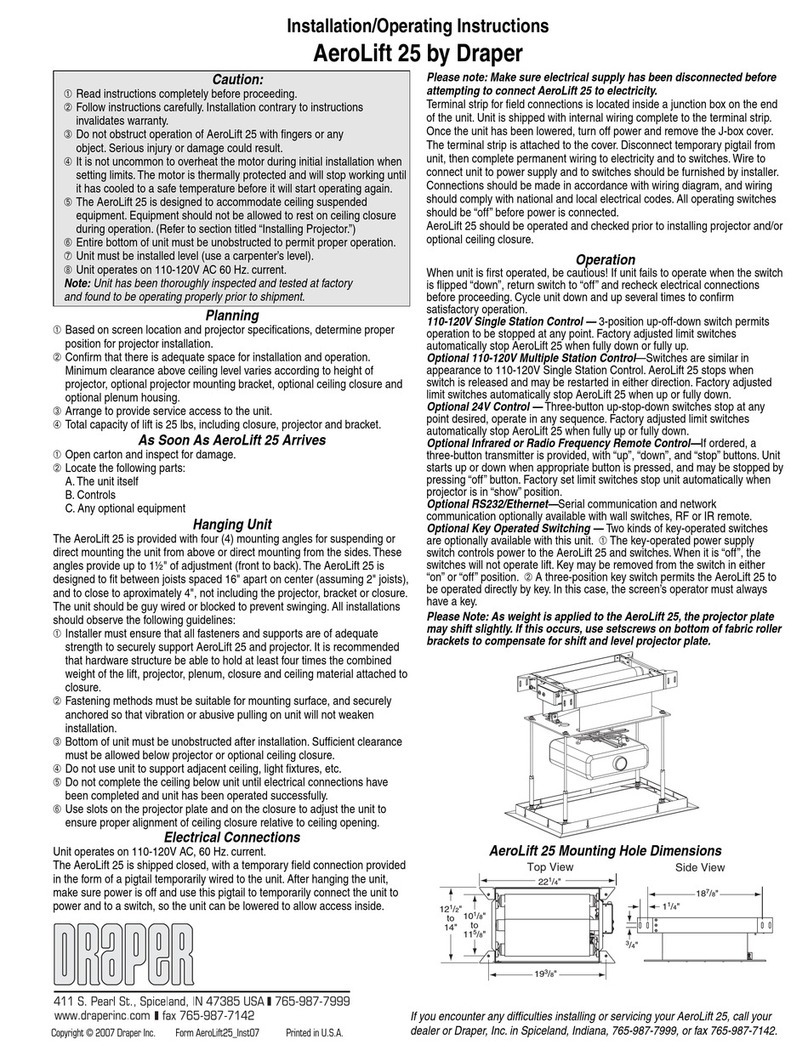

533 mm 528 mm

Min. 127 mm

Max. 1346 mm

Varies with

projector/bracket

and room

conditions