Draper SLX 110V Programming manual

CAUTION

Read and understand

all warnings

(Page 2

of this document)

before

beginning installation.

Contents

Overview - Components.......................................................................................1

Overview - Planning ..............................................................................................1

PLEASE READ - Safety Information....................................................................2

Section 1 - Hanging Unit ......................................................................................3

Section 2 - Operation............................................................................................3

Section 3 - Adjusting for Level or Center of Gravity........................................4

Section 4 - Installing Projector ...........................................................................4

Section 5 - Attaching Universal Projector Mount to Projector Pan..............4

Section 6 - Installing Optional Environmental Air Space Housing ...............5

Installing Optional Ceiling Trim Kit .............................................................................5

Section 7 - Installing Ceiling Closure.................................................................5

Section 8 - Connecting Controls to Data Cable Splitter Board ....................6

Section 9 - Clearing and Resetting Show Position..........................................6

Section 10 - Optional Delay Feature...................................................................6

Section 11 - Electrical Connections...................................................................7

Section 12 - Operation..........................................................................................7

Section 13 - Testing Safety Limit Switches.......................................................7

Section 14 - Adjusting Limit Switches ...............................................................7

Section 15 - Wiring Schematic............................................................................8

Section 16 - Dimensions ......................................................................................8

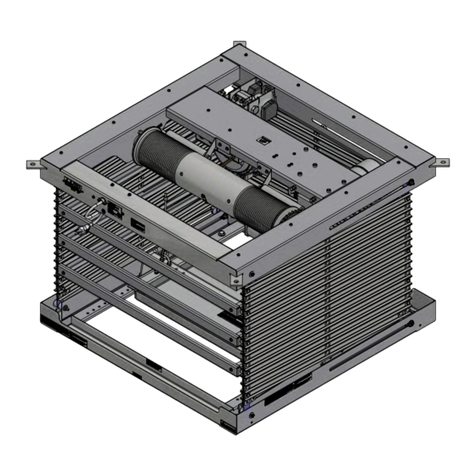

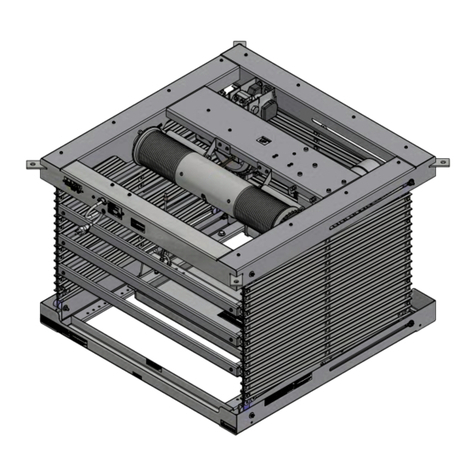

Overview - Components

Overview - Planning

1.

Based on screen location and projector

specifications, determine proper position for

projector installation.

2.

Confirm that there is adequate space for

installation and operation. Minimum clearance

above ceiling level varies according to height

of projector, optional projector mounting

bracket, optional ceiling closure and optional

Environmental Housing.

3.

Arrange to provide service access to the unit.

4.

When installed with Environmental Air Space Housing

unit is suitable for use in an environmental air space

in accordance with Section 300.22

(C)

of the National

Electrical Code, and Section 2-128, 12-010

(3)

and 12-100 of

the Canadian Electrical Code, Part 1, CSA C22.1.

5.

Total capacity of lift including cables, closure, projector,

and bracket:

As Soon As Lift Arrives

1.

Open carton and inspect for damage.

2.

Locate the following parts:

A.

The unit itself

B.

Controls

C.

Any optional equipment

SLX10 453 LBS 205KG

SLX14 435 LBS 197KG

SLX17 418 LBS 190KG

SLX21 393 LBS 178KG

SLX24 375 LBS 170KG

SLX28 350 LBS 159KG

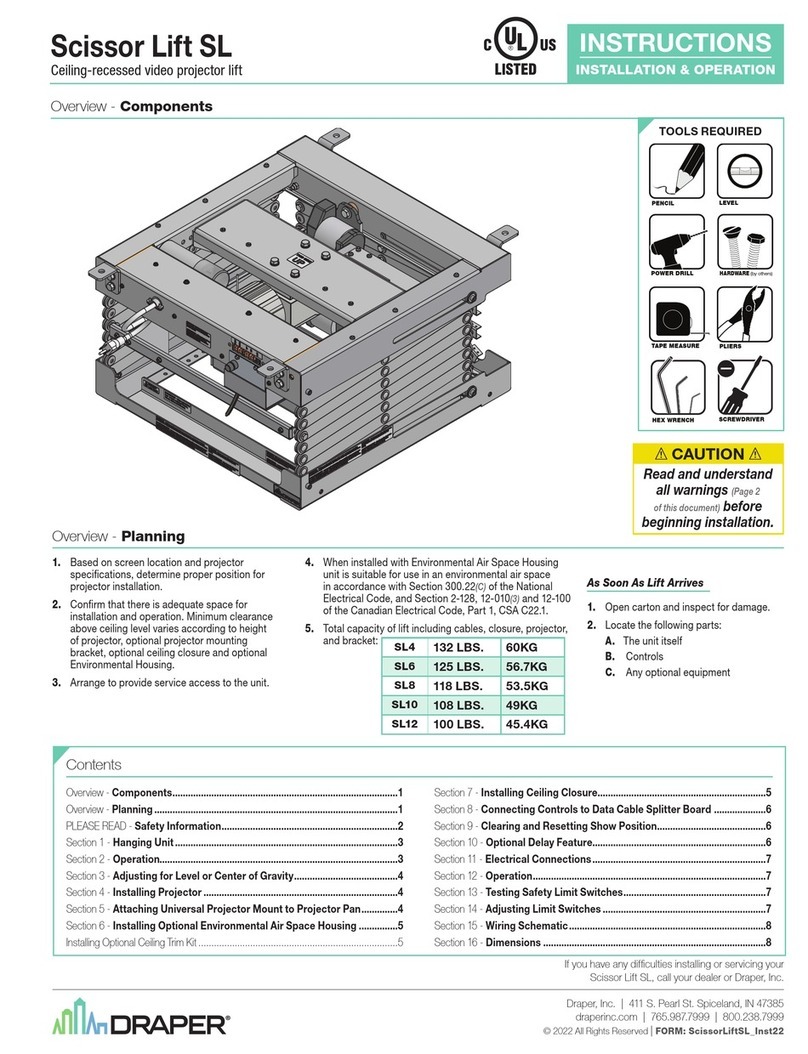

TOOLS REQUIRED

POWER DRILL

PENCIL

TAPEMEASURE

HARDWARE

(by others)

LEVEL

PLIERS

HEX WRENCH

SCREWDRIVER

Draper, Inc. | 411 S. Pearl St. Spiceland, IN 47385

draperinc.com | 765.987.7999 | 800.238.7999

© 2022 All Rights Reserved | FORM: ScissorLiftSLX_110UL_Inst22

Scissor Lift - SLX 110V

Ceiling-recessed video projector lift

INSTRUCTIONS

INSTALLATION & OPERATION

If you have any difficulties installing or servicing your

Scissor Lift SLX, call your dealer or Draper, Inc.

WARNING

Improper installation and use of the Scissor Lift can result in serious injury or death. Primarily, injuries can occur if the unit falls due to imprecise

installation, mishandling of the unit during installation, or installation on an insufficient wall or ceiling structure. Please use extreme care.

1.

Please read the following installation guidelines thoroughly and follow them

carefully. Failure to do so may cause product to fall or otherwise fail, and

could result in serious injury.

WARNING/AVERTISSEMENT

RISK OF ELECTRIC SHOCK. DO NOT OPEN

RISQUE DE CHOC ELECTRIQUE. NE PAS OUVRIR.

DANGER: To reduce risk of shock:

2.

Always disconnect power from lift before cleaning.

WARNING–To reduce risk of burns, fires, electric shock or injuries to persons:

3.

Turn off power and any nearby equipment or cables carrying electricity before

connecting switches, wires, controls, or electrical components.

4.

Use this lift only for its intended use as described in these instructions.

Do not use attachments not recommended by the manufacturer.

5.

Never operate this lift if it has a damaged cord or plug. If it is not working

properly, call your dealer or the manufacturer for assistance/repair.

6.

Keep cords away from heated surfaces.

7.

Never operate lift with air opening blocked. Keep openings free of debris.

8.

Never drop or insert any object into any opening.

9.

Do not use outdoors.

10.

Do not wire motors in parallel without written permission from Draper, Inc.

11.

Test lift prior to installation.

12.

During testing or operation, carefully watch the surrounding area for any

potential safety concerns including nearby persons or objects.

13.

After installation, the entire system, including all sensors, should be

carefully tested to ensure safe and normal operation. Extreme care should be

taken during testing to remain clear of moving parts to avoid possible injury.

14.

WARNING –

To prevent operation by unauthorized persons the locking switch

cover MUST be installed over the 3-button wall switch for installations where the

lift show position will descend to a height less than 8 feet above the floor. The

actuating switch controls shall be located within sight of the projector lift.

15.

Operation of unit should be performed only by authorized and qualified

personnel, who have been trained in its safe and effective operation and

understand its safety features.

16.

The safety features of the unit should never be disabled, bypassed, or

overridden. The system should not be operated until all safety features are

properly and completely installed, calibrated, and tested.

17.

Unit may need to comply with local, state, or district rules and regulations,

in particular when installed in schools. All applicable rules and regulations

should be reviewed before installation and use.

WARNING: Risk of Electric Shock—connect this product to a properly

grounded electrical supply.

PLEASE READ - Safety Information

Important Safety Information Important Safety Information

Important installation/operating Instructions

WARNING: To prevent injury, this apparatus must be securely attached to the

building structure in accordance with the instructions.

Caution:

Do not operate lift without a minimum of 15 lbs. of weight attached to

the pan. Operating without weight may cause cables to unspool.

18.

Installation and calibration of the unit should only be performed by an

authorized, qualified, and experienced professional. In particular, electrical

work and wiring [indicated in diagram by dashed lines] must be completed

only by a qualified professional electrician who has read this manual

completely and is familiar with the construction and operation of this

equipment and the hazards involved.

19.

Do not affix the unit to walls or ceilings that have inadequate strength

to permanently hold the unit during use. It is the owner’s and installer’s

responsibility to confirm the wall or ceiling to which the unit attaches is

sufficient to permanently hold the weight and stress loads of the unit at all

times. Draper®, Inc., is not responsible for improper installation, application,

testing, or workmanship related to the product at place of installation.

20.

It is the installer’s responsibility to make sure appropriate fasteners are used

for mounting.

21.

All hardware must be installed level. Unit must be level and square.

22.

Never leave the area while operating the unit during installation,

maintenance, or normal operation, unless it is secure and safe.

23.

Before testing or operation, carefully inspect the entire area and path

(especially underneath)

of unit to be sure no persons or objects are in the area.

24.

Failure to precisely follow installation guidelines invalidates all warranties.

25.

Do not obstruct operation of Scissor Lift with fingers or any object. Serious

injury or damage could result.

26.

Lift to be used with product weighing no more than: See chart on page 1.

27.

Scissor Lift is designed to accommodate ceiling suspended equipment.

28.

Equipment should not be allowed to rest on optional ceiling closure during

operation

(refer to section titled “Installing Projector”)

.

29.

Entire bottom of unit must be unobstructed to permit proper operation.

Sufficient clearance must be allowed below projector or optional ceiling

closure: 10' for Model SLX10, 14' for Model SLX14, etc.

30.

Unit operates on 115V AC 60 Hz. current.

14 amps current draw

(2 amps for lift, 12 amps for outlet)

.

31.

Verify the show position when testing lift. Make required changes by

referring to adjustment instructions on page 4 of this document.

32.

WARNING –

To prevent risk of injury, verify that no person is in the

vicinity of the device before raising or lowering.

33.

The maintenance/service factory limit setting must not be adjusted to a

lower position than the preset factory limit setting. In addition, Draper does

not recommend setting show position at the maintenance/service position—

for example, if you wish to have 8 foot show position, order a lift with at least a

10 foot maintenance position.

34.

When the Scissor Lift is to be installed in “other space used for

environmental air” the optional environmental air space housing must be

installed per instructions to isolate the lift from the “other space used for

environmental air.”

35.

When Scissor Lift is NOT installed in environmental air space housing

and optional ceiling closure, the ALTERNATE wiring for up limit switch may be

used

(see Alternate Wiring schematic on page 5)

.

36.

Custom products/installations may not be reflected in this manual. Call

Draper, Inc., if you have questions about the installation of custom products

or any questions about your installation.

Caution:

Before servicing unit, disconnect hardwired control and remote control.

Note: Unit has been thoroughly inspected and tested at factory and found

to be operating properly prior to shipment.

page 2 of 8

Scissor Lift - SLX 110V UL

Section 1 - Hanging Unit

Please note: If using Environmental Air Space Housing option, see installation instructions included with Environmental Air Space Housing.

The Scissor Lift may be installed in a variety of ways; recessed above the ceiling, or suspended below the ceiling. The lift should be supported by four

⁄

" threaded

mounting rods or bolts with locking nuts.

If ceiling recessed, the entire unit

(including the projector)

should set approximately 1½" above the finished ceiling in its “stored” position. The threaded rods should pass

through the corner mounting flanges and be secured by nuts above and below. The unit should then be guy wired or blocked to prevent swinging.

Please Note: Scissor Lift must be installed in accordance with the requirements of the Local Building Codes, the Canadian Electrical Code

(CEC)

, CAN/CSA C22.1 and

the National Electric Code

(NEC)

, NFPA 70, as required. An appropriate disconnect device shall be provided as part of the building installation.

All installations should observe the following guidelines:

1.

Installer must ensure that all fasteners and supports are of adequate

strength to securely support Lift and projector. Hardware structure

should be able to hold at least four

(4)

times the combined weight of the

lift, projector, housing, closure, and ceiling material attached to closure.

2.

Fastening methods must be suitable for mounting surface, and securely

anchored so that vibration or abusive pulling on unit will not weaken

installation.

3.

Bottom of unit must be unobstructed after installation. Sufficient

clearance must be allowed below projector or optional ceiling closure.

4.

Do not use unit to support adjacent ceiling, light fixtures, etc.

5.

Do not complete the ceiling below unit until electrical connections have

been completed and unit has been operated successfully.

CAUTION:

BEWARE OF PINCH POINTS!

6.

Use slots on the projector plate and on the closure to

adjust the unit to ensure proper alignment of ceiling

closure relative to ceiling opening.

CAUTION: DO NOT hang from, "ride," or pull down on

the unit. This could create a failure and cause damage

and/or injury.

7.

When Lift is NOT installed in environmental air space

housing and optional ceiling closure, the ALTERNATE

wiring for 'UP' limit switch may be used. Disconnect

both BLACK

(BK)

wires from 'UP' limit switch and

quick connect them together using the provided

jumper cable

(see Alternate Wiring schematic on page ?)

.

Section 2 - Operation

Before operating or testing the unit, make sure the packaging has been removed from the unit. Remove the corrugated block from the cardboard sleeve

(bottom-most

packaging material)

, then collapse the sleeve and remove it, along with the rest of the packaging. Next, using the 3 button switch, operate the lift in the "up" direction, so

the lift's control encoder will recognize it's "home" location. Until you do this, the Down function will not work. You must also do this if the Scissor Lift ever loses or is

disconnected from the power.

When unit is first operated, be cautious! If unit fails to operate properly, press “STOP” and recheck electrical connections before proceeding. Cycle unit down and up

several times to confirm satisfactory operation.

Caution: Do not pull on or touch safety belt when unit is in motion. If belt locks, the cables will unspool.

WARNING: To prevent operation by unauthorized persons the locking switch cover MUST be installed over the 3-button wall switch for installations where the lift

show position will descend to a height less than 8 feet above the floor. The actuating switch controls shall be located within sight of the projector lift.

WARNING: To prevent risk of injury, verify that no person is in the vicinity of the device before raising or lowering.

Caution: Obstructing bottom pan may cause cables to unspool.

Caution: Do not operate Scissor Lift without a minimum of 15

lbs. of weight attached to the pan. Operating without weight

may cause cables to unspool.

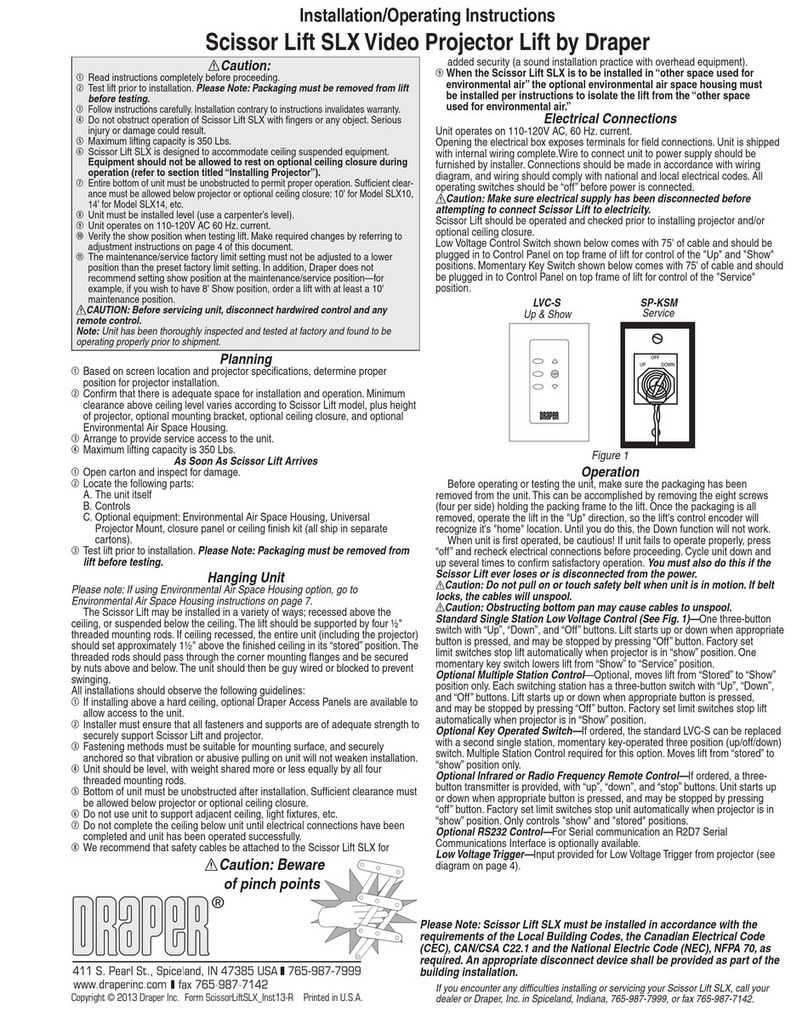

Standard Single Station Low Voltage Control

(Fig. 1)

One three-button switch with “UP”, “DOWN”, and “STOP” buttons.

Lift starts up or down when appropriate button is pressed, and may

be stopped by pressing “STOP” button. Factory set limit switches

stop lift automatically when projector is in “show” position. One

momentary key switch lowers lift from “show” to “service” position.

Optional Multiple Station Control

Optional, moves lift from “stored” to “show” position only. Each

switching station has a three-button switch with “UP”, “DOWN”,

and “OFF” buttons. Lift starts up or down when appropriate button

is pressed, and may be stopped by pressing “OFF” button. Factory

set limit switches stop lift automatically when projector is in “show”

position.

Optional Key Operated Switch

If ordered, the standard Lift LV Switch can be replaced with a second

single station, momentary key-operated three position

(up/off/down)

switch. Multiple Station Control required for this option. Moves lift

from “stored” to “show” position only.

Optional RS232 Control

For Serial communication an R2D7 Serial Communications Interface

is optionally available.

Optional Infrared or

Radio Frequency Remote Control

If ordered, a three-button transmitter is

provided, with “UP”, “DOWN”, and “STOP”

buttons. Unit starts up or down when

appropriate button is pressed, and may be

stopped by pressing “OFF” button. Factory

set limit switches stop unit automatically when

projector is in “show” position. Only controls

"show" and "stored" positions.

Low Voltage Trigger

Input provided for Low Voltage Trigger

from projector

(see diagram on page 4)

.

FRONT SIDE BACK

LIFT LV SWITCH

Up & Show

UP DOWN

OFF

SP-KSM

Service

LIFT LV SWITCH WITH

LOCKING COVERPLATE

LVC-S With

Locking Coverplate

page 3 of 8

Scissor Lift - SLX 110V UL

3"

(100mm)

12"

(304mm)

2"

(52mm)

7"

(178mm)

Section 5 - Attaching Universal Projector Mount to Projector Pan

Figure 4

Please Note: If unit is ordered with optional Universal Projector Mount pre-installed, disregard these instructions.

If unit is NOT ordered with optional Universal Projector Mount pre-installed, it is necessary to install a new Projector Pan, which includes the Universal Projector

Mount's rectangular plate.

1.

Lower unit until the Bottom Pan is resting on a tabletop or other stable and sturdy surface.

2.

Remove Lifting Cable Bar from Bottom Pan.

3.

Remove bolts holding Projector Pan to Bottom Pan.

4.

Remove Projector Pan and set aside.

5.

Place new Projector Pan with Universal Mount into place.

6.

Re-attach Projector Pan to Bottom Pan.

7.

Re-attach Lifting Cable Bar to Bottom Pan.

Preferred Method—Adjusting Projector Pan

The Projector Pan can be moved forward or back.

1.

Ensure Bottom Pan is supported.

2.

Remove the Lifting Cable Bar.

3.

Remove screws holding Projector Pan on Bottom Pan.

4.

Move Projector Pan forward or back.

5.

Replace screws.

6.

Replace Lifting Cable Bar.

Secondary Method—Adjusting Lifting Cable Bar

(if above does not work)

1.

Run unit to its "Service" position and ensure Bottom Pan is level.

2.

Ensure Bottom Pan is not more than ¾"

(19mm)

out of level. However, the pan does

not have to be perfectly level, as long as its positioning is consistent and repeatable

in "Show" and "Closed" positions.

3.

Ensure Bottom Pan is supported.

4.

Remove screws holding Lifting Cable Bar to the Projector Pan.

5.

Move Lifting Cable Bar forward or back.

6.

Replace screws.

7.

Check level again. If still not level, repeat.

Section 3 - Adjusting for Level or Center of Gravity

"

(9.5mm)

-18 x 1"

(25mm)

hex head

cap screws for

attaching Lifting

Cable Bar to Bottom Pan

BOTTOM PAN

PROJECTOR PAN

LIFTING CABLE BAR

"

(9.5mm)

-18 x 1"

(25mm)

hex head

cap screws for attaching

Lifting Cable Bar to Bottom Pan

Section 4 - Installing Projector

Draper’s optional Universal Projector Mount will hold up to 26 lb

(12kg)

.

See Installation Instructions included with Universal Projector Mount.

If not using Draper’s Universal Projector Mount, generally the video projector

should be suspended from the bottom pan

according to projector manufacturer’s instructions.

If installing with a small closure, maximum projector size is:

18" x 8¾"

(45.7 x 22.2 cm)

(width x length x Environmental Air Space Housing height)

.

If installing with a large closure, maximum projector size is:

18" x 18"

(45.7 x 45.7 cm)

(width x length x housing height)

.

The projector plate is not pre-drilled.

When drilling initial holes for mounting projector, or if for any reason the hole

placement must be changed, completely lower lift before attempting to drill

holes. When attaching projector bracket to plate, make sure screws are short

enough that they do not touch the motor/roller above the plate when lift is

closed.

Unit and projection system should be operated, checked and adjusted as necessary at this time

(see Sec. 8 for limit adjustment procedures)

.

CAUTION: Keep fingers & other objects away from ceiling closure when unit is operating. Serious injury or damage can result.

5"

(140mm)

2"

(64mm)

12"

(305mm)

12"

(305mm)

10"

(254mm)

7"

(178mm)

5"

(140mm)

2"

(64mm)

12"

(305mm)

12"

(305mm)

10"

(254mm)

7"

(178mm)

5"

(140mm)

2"

(64mm)

12"

(305mm)

12"

(305mm)

10"

(254mm)

7"

(178 m m)

page 4 of 8

Scissor Lift - SLX 110V UL

Section 6 - Installing Optional Environmental Air Space Housing

The Environmental Air Space Housing ships in pieces, and must be assembled by the

installer. Height is set by drilling out the knockouts at the desired locations then using

screws to connect side panels.

Draper recommends installing an access panel in the ceiling to allow future access.

The optional Environmental Air Space Housing must be installed to isolate the lift from

the “other space used for environmental air.” Includes trim ring for ceiling opening.

See installation instructions included with Environmental Air Space Housing.

Please Note: When using the Environmental Air Space House "SL" size,

the mounting brackets attached to the top four corners of the Scissor Lift

must be removed, and replaced with brackets which are shipped with the

Environmental Air Space Housing

(see Fig. 5)

.

Please Note: The factory wiring of 'UP' Limit Switch MUST ALWAYS be used

when SL is installed in Environmental Air Space Housing and optional ceiling

closure.

Lower section of

Environmental

Air Space Housing

CEILING TILE

(by others)

TRIM RING

Installing Optional Ceiling Trim Kit

1.

Install Lift.

2.

Install bottom section of

housing in opening by

suspending with wire, or by

mounting directly to the ceiling

joists

(if space permits)

.

3.

Install projector and attach

optional ceiling closure.

For Additional Safety:

1.

Be sure the nuts that attach the threaded

rods to the closure panel are tight.

2.

Wrap a plastic wire tie around the mounting

tab and the threaded rod at all four corners

of the closure panel.

Please Note: Do NOT use a paper-covered or similar

wire tie — use only plastic wire ties for maximum safety.

Section 7 - Installing Ceiling Closure

If unit is equipped with a ceiling closure system, use either as is, or in conjunction with a piece of existing ceiling tile.

Please refer to diagrams at right for instructions.

1.

If installing with ceiling tile, it may be necessary to cut tile so overall dimensions are same as

(or slightly less than)

closure panel. Place tile into trim frame. Lay closure panel on top

(back side)

of ceiling tile, and tighten screws to

hold in place.

2.

If installing large closure, attach brackets to bottom of projector plate.

3.

Attach

⁄

"

(8mm)

threaded rods to slots in projector plate or brackets.

CAUTION: Ensure nuts and bolts attaching brackets to Lift are completely tightened.

4.

Run unit "up" until bottom pan stops at highest position. Mark position on

⁄

"

(8mm)

rods flush with ceiling

level and cut rods to length

(removing from pan if convenient)

.

5.

Run unit "down" until bottom pan stops at "show" position.

6.

Attach closure to lower end of

⁄

"

(8mm)

rods by slipping into four corner slots and secure with nuts above and

below slots.

7.

Run unit "up" again to highest position. Measure distance by which panel fails

to reach required "closed" height for surrounding ceiling.

CAUTION: Make sure nuts are completely tightened.

8.

Run unit "down" then re-adjust mounting of

⁄

"

(8mm)

rods in traveling grid to

raise panel required distance.

9.

Test unit operation to confirm that panel will stop in closed position just before

touching ceiling.

CAUTION: DO NOT hang from, "ride," or pull down on unit. This could create

a failure and cause damage and/or injury.

PLEASE NOTE: Immediately upon completing surrounding ceiling, operate unit

to confirm that optional ceiling closure panel stops

⁄

"

(3mm)

short of ceiling in

closed position. If closure panel touches ceiling, motor may continue operating

after lift is closed. If it continues to cycle once lift is closed, a failure may occur,

making unit descend rapidly and cause damage and/or injury.

page 5 of 8

Scissor Lift - SLX 110V UL

Figure 7

Please Note:

Any control, including automated

dry contact systems, being

connected to the wall switch input

MUST send a momentary signal.

NOTICE -

Delay Feature Will

Not Operate Properly Without

The Optional Current Sensor

Connected To The Lift.

KEEP DELAY IN OFF POSITION WHEN

CURRENT SENSOR IS NOT USED

Section 8 - Connecting Controls to Data Cable Splitter Board

Section 9 - Clearing and Resetting

Show Position

Clearing the show position at current show position:

1.

Move lift to the show position.

2.

While lift is at the show position press and hold the Key Up toggle

switch and release once the Lift begins moving upward.

3.

The show position is now cleared and ready for a new show

position to be set.

PLEASE NOTE: At this point the Key Switch will not operate until the

new “Show Position” has been set. Also the 3-Button Wall Switch

changes into a maintain, push and hold type button, for continuous

movement. This allows for easy setting of new “Show Position”)

Procedure for setting show position:

1.

Now that the show position has been cleared, use wall switch up

and down buttons to get lift into desired show position.

2.

While lift is at desired show position, press and hold the Key Down

toggle switch until lift begins to move upward. Lift will begin a

calibration cycle where it will move upward for two seconds, stop

then move down for one second and then the Lift will return to the

desired show position.

Section 10 - Optional Delay Feature

1.

When the Optional Delay Feature is installed the Delay Switch must be in

the "Delay On" position for normal operation.

2.

If the Optional Delay Feature is installed and the "Show Position"

requires adjusting, then the "Delay Switch" must be switched to OFF

while adjusting the show position.

CAUTION: Be sure all switches are in OFF position before adjusting

limit switch. Always be prepared to shut lift off manually when new

adjustment is being tested. Please refer to wiring diagram.

PLEASE NOTE: If the Scissor Lift loses power, the DOWN function will not

work until you operate the lift in the UP direction using the wall switch.

This allows the lift's control encoder to recognize it's "home" location.

1.

Controls plug into the Data Cable Splitter Board

(See diagram below)

which is located

on the Top Frame on the front side of the lift, using RJ

⁄

P4C connectors.

2.

For IR or RF Remote Control, use data cable with RJ

⁄

P4C

connectors on both ends.

3.

For serial control of "Show"

position, use data cable with

RJ

⁄

P4C connectors on both

ends and an R2D7 Serial

Control Interface.

4.

Plug into the "RP/RQ" input.

KEY

WALL

RP/RQ

RP/RQ

LVT

Red - Down

Black - Com

Black - Com

Blue - Up

Pin 3 - Green

Pin 2 - Yellow

Pin 5 - Black

DCU

Green - DOWN

Black - COM

Yellow - UP

PIN

1 - NOT USED

2 - YELLOW

3 - GREEN

4 - NOT USED

5 - BLACK

6 - NOT USED

Please Note:

Data cable connections must be

made using electrically straight

6 Pin 4 conductor modular cable

(RJ14/6P4C).

Please Note:

RJ14/6P4C

Data Cables

for Serial Control

Provided by Others

LVC-S

Show Position

Automated

Dry Contact

System

To RS232 Serial Port:

1 - Blue = Not Used

2 - Yellow = Rx

(Data from control system)

3 - Green = Tx

(Data to control system)

4 - Red = Not Used

5 - Black = Gnd (Signal Ground)

6 - White = Not Used

SP-KSM

Key Switch

Service Position

Optional

R2D7,

RS232 Controller

RP/RQ Bus Ports for remote controls

such as IR Eye, RF Receiver,

LED Wall Switch and RS232.

Low Voltage Trigger

(6-24 VDC)

(Polarity Independent)

DETAIL OF DATA CABLE

SPLITTER BOARD

Function

Indicator

page 6 of 8

Scissor Lift - SLX 110V UL

Section 13 - Testing Safety Limit Switches

CAUTION: Lift is equipped with two Safety Limit Switches

(see "Adjustments")

.

This switch may be damaged during shipping or by rough handling on the

job site.

1.

After the Lift has been installed in the ceiling, but before the projector and

closure are attached, the Safety Limit must be tested.

2.

Use a screwdriver or other tool to hold down the Safety Limit Switch. While

holding down Safety Limit Switch, other installer should operate the unit. If

the unit works, Safety Limit Switch is broken and must be replaced.

CAUTION: Operating the unit without a functioning Safety Limit Switch

could cause the unit's motor to continue operating after the lift is closed,

leading to a failure and the possibility of damage or injury.

Please Note: As weight is applied to the Lift, the projector plate may shift

slightly. If this occurs, use set screws on bottom of fabric roller brackets to

compensate for shift and level projector plate.

Section 12 - Operation

CAUTION: When operating for the first time, cycle unit down and up several

times to confirm satisfactory operation. Be prepared to cut POWER if

necessary.

•

110-120V SINGLE STATION CONTROL - 3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

•

24V CONTROL - 3-button UP-STOP-DOWN switches stop at any point desired

and operate in any sequence. Factory adjusted limit switches automatically

stop screen when fully up or fully down. Installer should incorporate an all-pole

disconnect in fixed wiring available with RF or IR remote.

•

KEY OPERATED SWITCHING - Two key-operated switches optionally

available with this unit:

•

Key-operated power supply switch controls power to screen and switches.

When "off", switches will not operate screen. Key may be removed from

switch in either "on" or "off" position.

•

Three-position key switch permits the screen to be operated directly by key.

Requires screen operator to have a key.

•

RS232 / ETHERNET - Serial communication and network communication

optionally available.

Section 11 - Electrical Connections

Lift operates on 115V, 60 Hz. current. 14 amps current draw

(2 amps

for lift, 12 amps for Outlet)

Lift ships with internal wiring complete and

control switch

(es)

fully boxed.

Wire to connect lift to switch

(es)

and switch

(es)

to power supply

should be furnished by installer.

Please Note: Lift must be installed in accordance with

requirements of Local Building Codes, Canadian Electrical Code

(CEC)

, CAN/CSA C22.1 and National Electric Code

(NEC)

, NFPA

70. An appropriate disconnect device shall be provided as part of

building installation.

CAUTION: All operating switches should be "off" before power

is connected.

Terminal strip for field connections is located inside a junction box

on the end of the unit. Unit ships with internal lift wiring complete to

terminal strip. Use switch to lower lift and remove packing. Remove

temporary wiring and complete permanent wiring to electricity and

to switches. Wire to connect unit to power supply and to switches

should be furnished by installer. Connections should be made

in accordance with wiring diagram. Lift should be operated and

checked prior to installing projector and/or optional ceiling closure.

Section 14 - Adjusting Limit Switches

Caution: The maintenance/service factory

limit setting must not be adjusted to a lower

position than the preset factory limit setting.

In addition, Draper does not recommend

setting show position at the maintenance/

service position.

PLEASE NOTE: Changing the fully open or fully closed position will reset the

electronic controls and cause the lift to operate improperly. Please call Draper

before attempting these adjustments.

Adjusting FULLY DOWN position

1.

Limit switches for the Scissor Lift are preset at the

factory. The DOWN limit switch is set for the fully down

(maintenance)

position for the size lift you have ordered.

The limit switch assembly is located inside the lift and

behind the Lifting Cable Drum.

2.

The Down limit switches shown in the drawing are for

setting the "Fully Down" position.

This can be adjusted manually by

loosening or tightening the screw

to increase or reduce the travel.

ROTATE

TO

ADJUST

DOWN

Limit

Switch

DOWN

page 7 of 8

Scissor Lift - SLX 110V UL

Scissor Lift Inspection and Maintenance

Draper recommends inspecting the Scissor Lift at least annually or every 300 cycles—whichever comes first.

A recommended maintenance schedule includes:

•

Cables: Check for fraying.

•

Drive Chain Gears: Check for

rust, breaks, secure attachment.

•

Fasteners along scissor arm assemblies: Make sure they are not loose.

If any are loose, hand tighten the nuts.

Please Note: There is no need to tighten nut in the top scissor which

slides back and forth in the side slot in the lift. Tightening this fasteners

assembly will cause the unit to lock up and lead to damage to the unit.

•

Closure: Ensure threaded rod remains

seated firmly in the closure panel

corners, and that nuts remain tight. If

they are loose, tighten them.

Section 15 - Wiring Schematic

Model Closed Height Extended Height

SL10 14

⁄

"

(35.6cm)

10'7"

(322.6cm)

SL14 16

⁄

"

(40.6cm)

14'2"

(431.8cm)

SL17 18

⁄

"

(45.7cm)

17'8"

(538.5cm)

SL21 20

⁄

"

(50.8cm)

21'3"

(662.9cm)

SL24 23

⁄

"

(58.4cm)

24'9"

(754.4cm)

SL28 25

⁄

"

(63.4cm)

28'5"

(8 6 6 .1cm)

Section 16 - Dimensions

36

3

/

16

"

(919mm)

38

5

/

16

"

(973mm)

35

9

/

16

" (903 mm)

37

11

/

16

" (957 mm)

Top View

1

/

8

"

(3.175mm)

35

7

/

16

" (900 mm)

37

1

/

16

" (941 mm)

42" (1067 mm)

36¼" (921 mm)

39

1

/

16

" (992 mm)

42" (1067 mm)

35" (889 mm)

1

9

/

16

"

(39.69mm)

Front View Side View

39

1

/

8

" (994mm) x 39

1

/

8

" (994mm)

Lipless Closure Dimensions

See

Table

A

36

3

/

16

"

(919mm)

38

5

/

16

"

(973mm)

35

9

/

16

" (903 mm)

37

11

/

16

" (957 mm)

Top View

1

/

8

"

(3.175mm)

35

7

/

16

" (900 mm)

37

1

/

16

" (941 mm)

42" (1067 mm)

36¼" (921 mm)

39

1

/

16

" (992 mm)

42" (1067 mm)

35" (889 mm)

1

9

/

16

"

(39.69mm)

Front View Side View

39

1

/

8

" (994mm) x 39

1

/

8

" (994mm)

Lipless Closure Dimensions

See

Table

A

N

U C D

Dashed wiring by electrician

115VAC,

Supply

WH

BKBK

WH

GN

WH

Low voltage wiring by others

WH Encoder

RD

BK

RD WH RD

WH

BK

WH

RD

BN

RD

WH

BK

YL

YL/GN

RD

BK

BK

OR

Up

Limit Switch

NC

NC

BK

BN NC

Down

Limit Switch

Delay Switch

(on position)

RD

BK

OR RD

RD

BK

BL

YL/GN

BK

Motor

Up

Down

BK

BK

BK

WH

OR

RD

BK

BK

WH

OR

RD

AC

AC

COM

N.O.

N.C.

BK

WH

RD

OR

Optional Delay Assembly

115VAC, 12A 60 Hz Outlet

Run Cap

45 MFD

2 Cond. Cable

Attached to

lower pan

Low Voltage Trigger (6-24 VDC)

Wall Switch

Key Switch

RP/RQ Bus Ports for

remote controls such

as IR Eye, RF Receiver,

LED Wall Switch and

RS232.

page 8 of 8

Scissor Lift - SLX 110V UL

Table of contents

Other Draper Scissor Lift manuals

Popular Scissor Lift manuals by other brands

EAE

EAE EE-65A.40T Installation, operation, and parts manual

MAHA

MAHA DUO CM Series operating instructions

Hy-Brid Lifts

Hy-Brid Lifts I Series Operation & safety manual

EAE

EAE EE-TS6600 Installation, operation, and parts manual

Vestil

Vestil CART-500-LA Operation and maintenance manual

ATN

ATN CX 12 Operator's and safety manual

Kleton

Kleton MJ519 instruction manual

POP UP

POP UP IQ LIFT PRO10 OPERATIONS & SAFETY HANDBOOK

Atlas Equipment

Atlas Equipment LR-06P Operation & installation manual

Sinoboom

Sinoboom GTJZ1330SE Operation manual

DINGLI

DINGLI JCPT2223RT operators manual with maintenance information

Atlas Equipment

Atlas Equipment 12ASL Installation & operation manual