Copyright © 2014 Draper Inc. Form ScissorLiftSLX-230V_Inst14-R Printed in U.S.A.

Planning

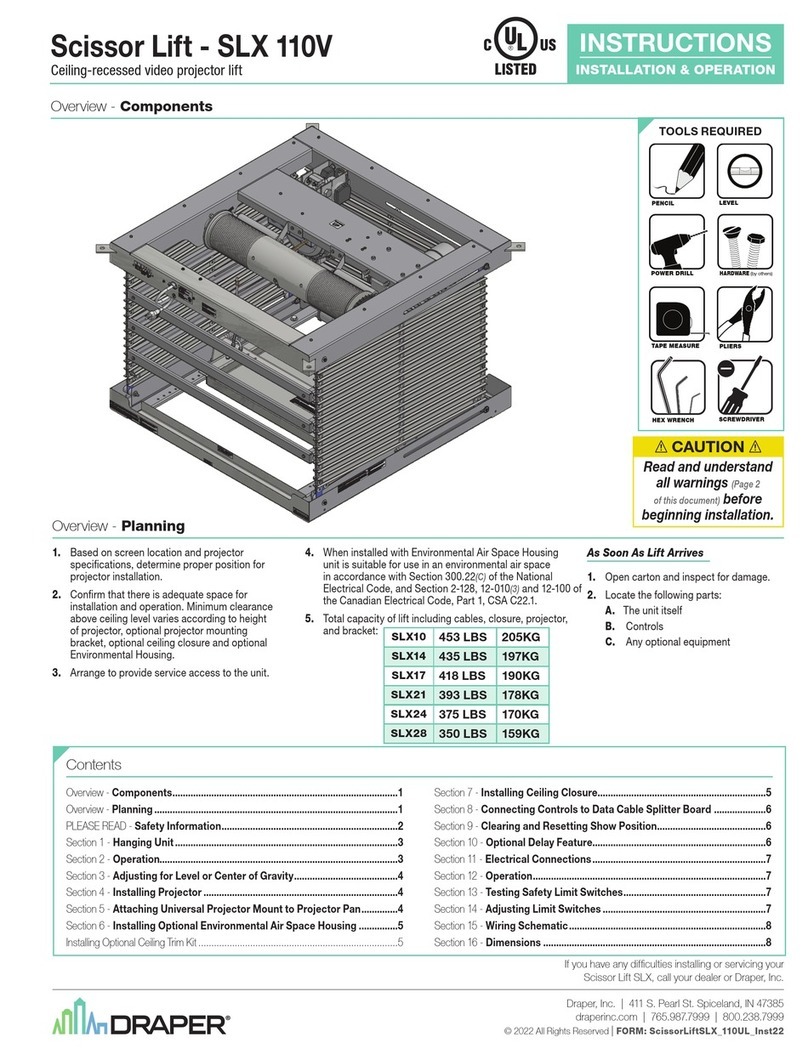

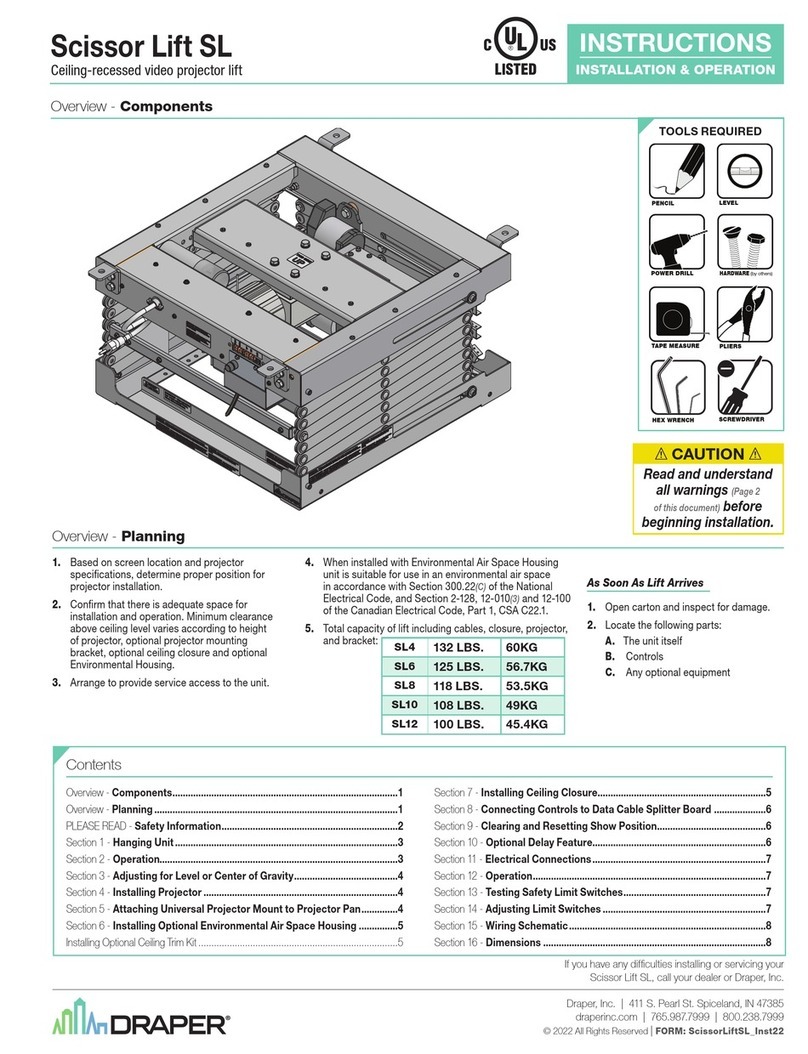

1Based on screen location and projector specifications, determine proper

position for projector installation.

2Confirm that there is adequate space for installation and operation. Minimum

clearance above ceiling level varies according to Scissor Lift model, plus height

of projector, optional mounting bracket, optional ceiling closure, and optional

Environmental Air Space Housing.

3Arrange to provide service access to the unit.

4Maximum lifting capacity is 159 kg.

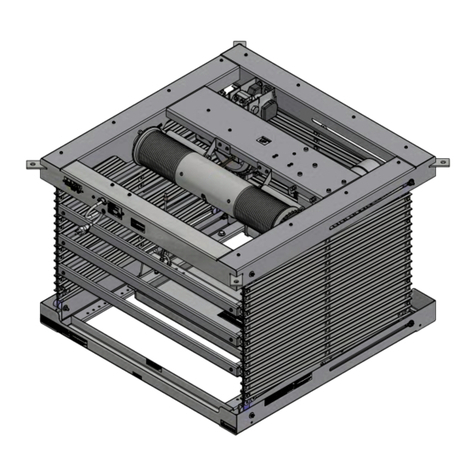

As Soon As Scissor Lift Arrives

1Open carton and inspect for damage.

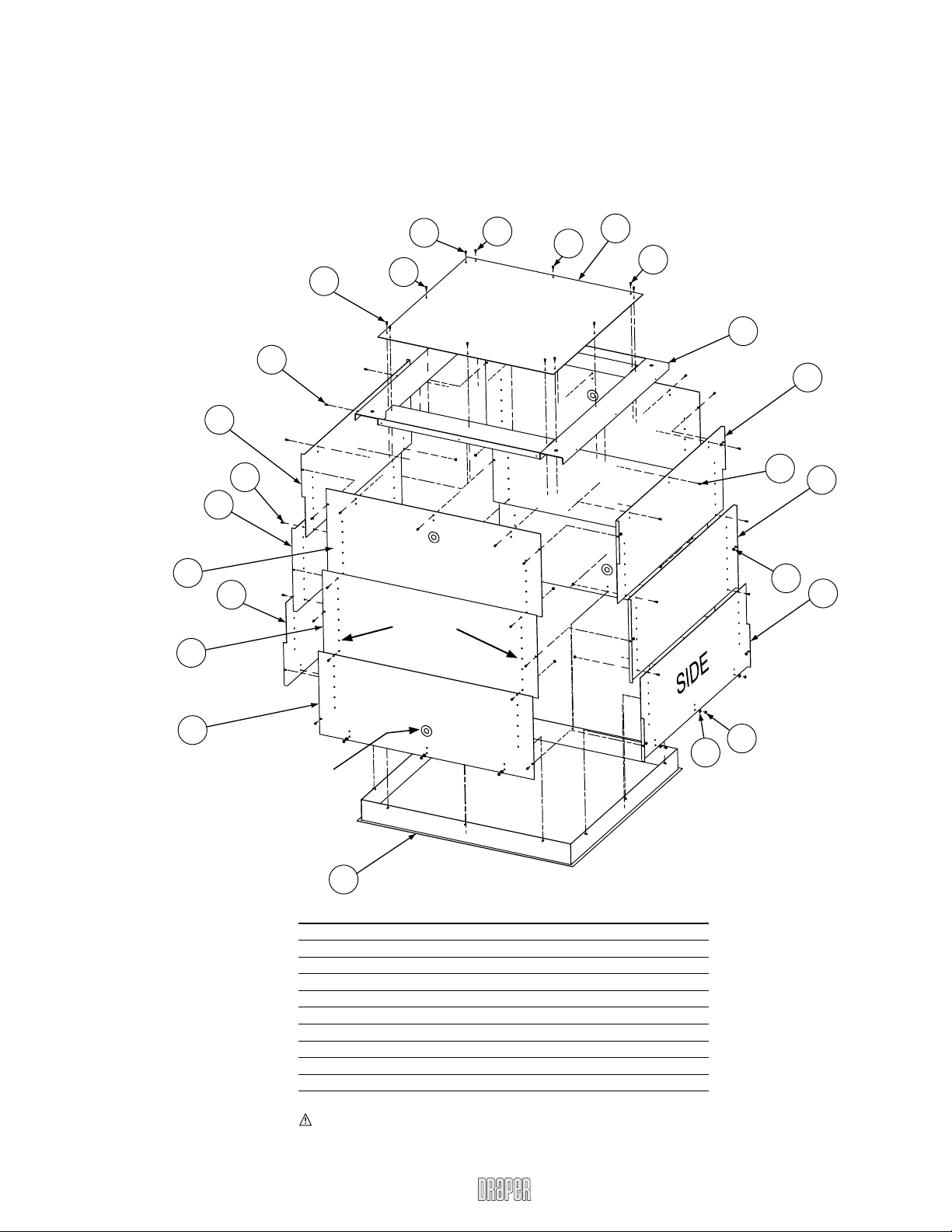

2Locate the following parts:

A. The unit itself

B. Controls

C. Optional equipment: Environmental Air Space Housing, Universal

Projector Mount, closure panel or ceiling finish kit (all ship in separate

cartons).

3Test lift prior to installation. Please Note: Packaging must be removed from

lift before testing.

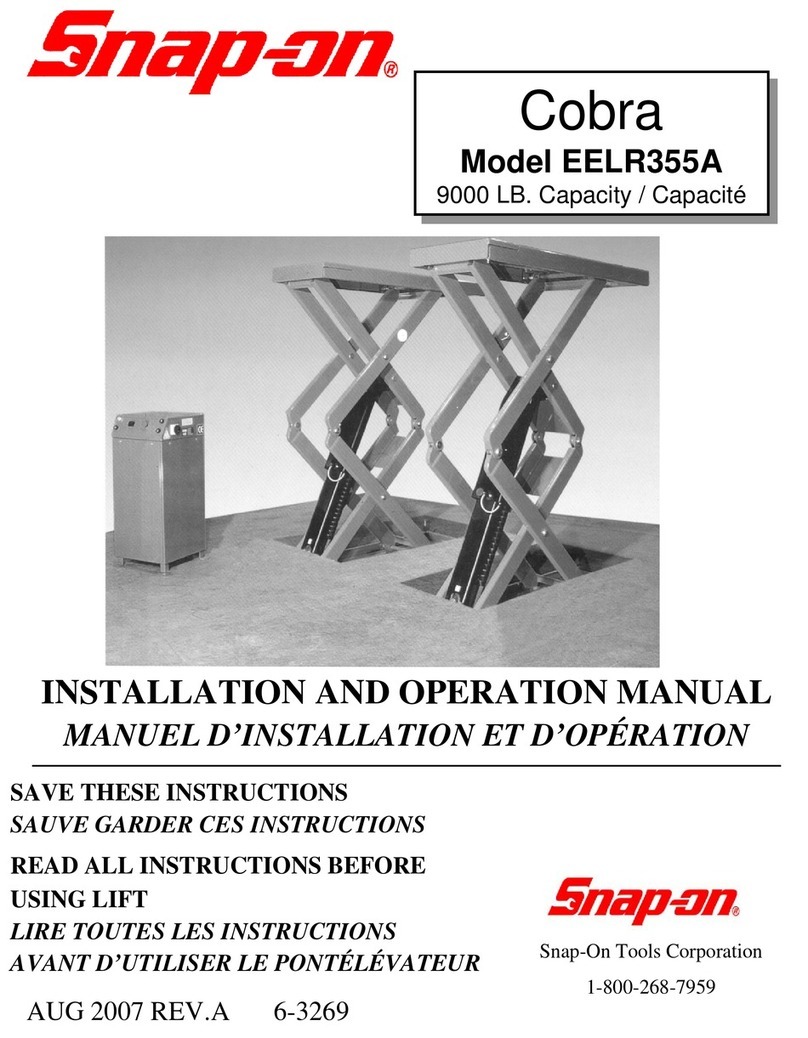

Installation/Operating Instructions

230V AC Scissor Lift SLX Video Projector Lift by Draper

Electrical Connections

Unit operates on 230V AC, 50 Hz. current. 5.4 amps current draw (2 amps for lift,

3.5 amps for outlet).

Opening the electrical box exposes terminals for field connections. Unit is shipped

with internal wiring complete.Wire to connect unit to power supply should be

furnished by installer. Connections should be made in accordance with wiring

diagram, and wiring should comply with national and local electrical codes. An

appropriate disconnect device shall be provided as part of the building installation.

All operating switches should be “off” before power is connected.

Caution: Make sure electrical supply has been disconnected before

attempting to connect Scissor Lift to electricity.

Scissor Lift should be operated and checked prior to installing projector and/or

optional ceiling closure.

Low Voltage Control Switch shown below comes with 22.8 m of non-plenum rated

If you encounter any difficulties installing or servicing your Scissor Lift SLX, call your

dealer or Draper, Inc. in Spiceland, Indiana, 765-987-7999, or fax 765-987-7142.

Operation

Before operating or testing the unit, make sure the packaging has been

removed from the unit. This can be accomplished by removing the eight screws

(four per side) holding the packing frame to the lift. Once the packaging is all

removed, operate the lift in the "Up" direction, so the lift's control encoder will

recognize it's "home" location. Until you do this, the Down function will not work.

When unit is first operated, be cautious! If unit fails to operate properly, press

“off” and recheck electrical connections before proceeding. Cycle unit down and

up several times to confirm satisfactory operation. You must also do this if the

Scissor Lift ever loses or is disconnected from the power.

Caution: Do not pull on or touch safety belt when unit is in motion. If belt

locks, the cables will unspool.

Caution: Obstructing bottom pan may cause cables to unspool.

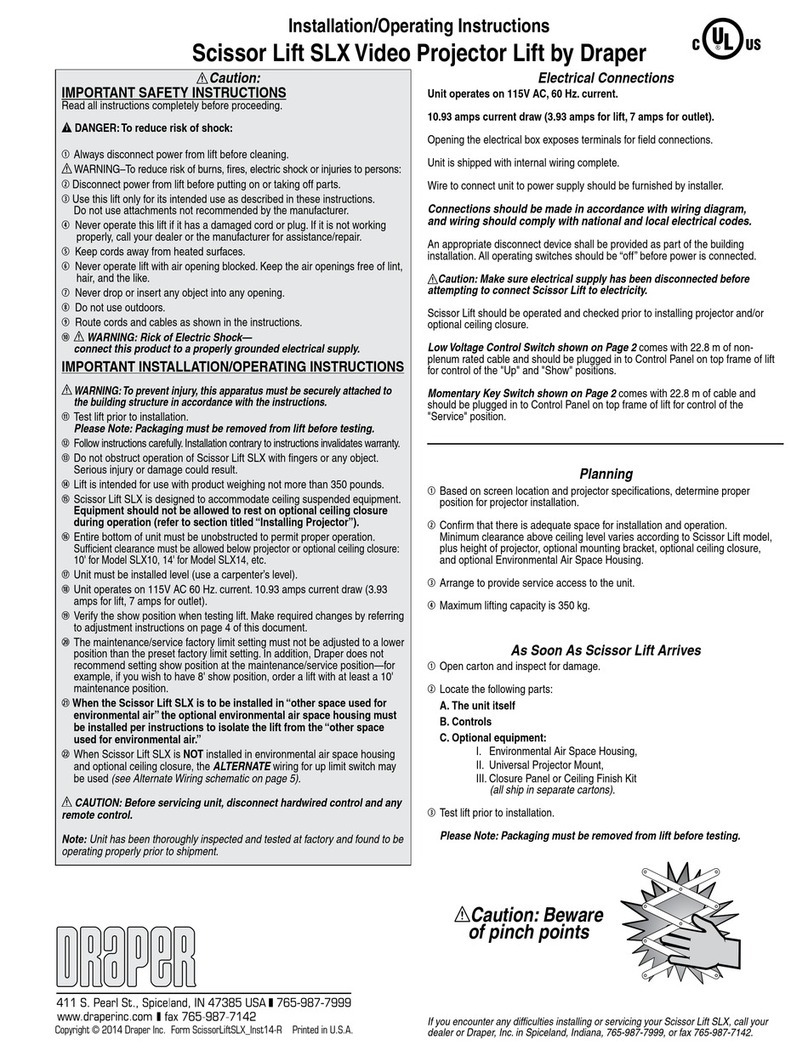

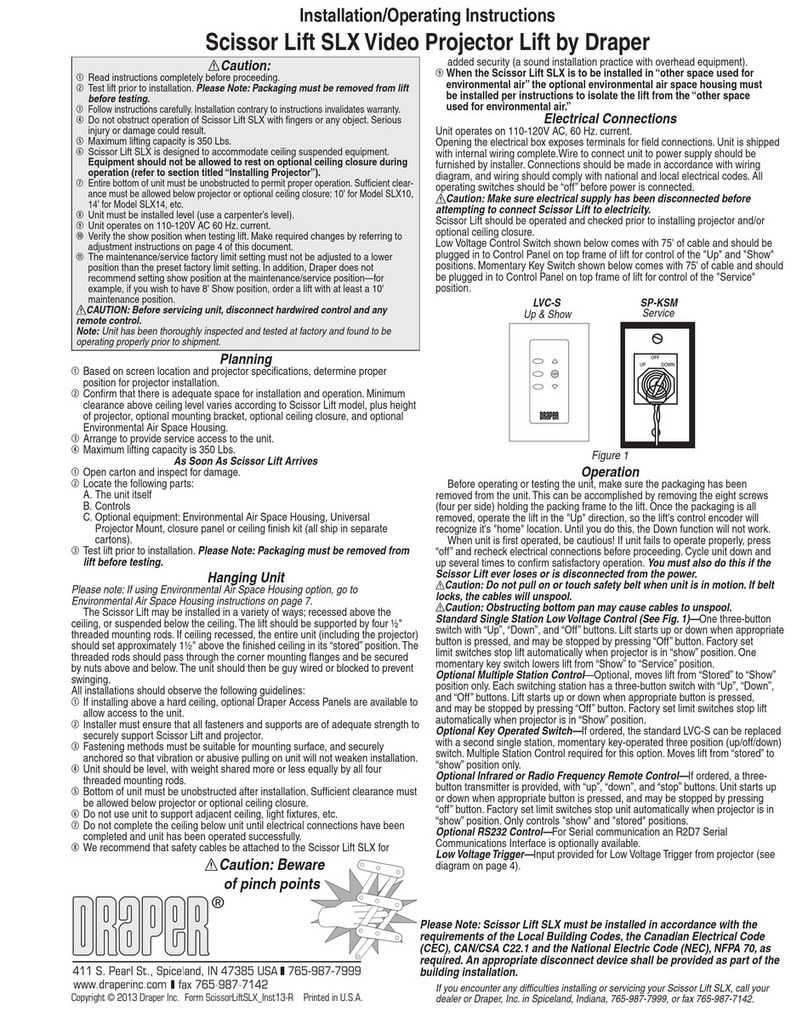

Standard Single Station Low Voltage Control (See Fig. 1)—One three-button

switch with “Up”, “Down”, and “Off” buttons. Lift starts up or down when appropriate

button is pressed, and may be stopped by pressing “Off” button. Factory set

limit switches stop lift automatically when projector is in “show” position. One

momentary key switch lowers lift from “Show” to “Service” position.

Optional Multiple Station Control—Optional, moves lift from “Stored” to “Show”

position only. Each switching station has a three-button switch with “Up”, “Down”,

and “Off” buttons. Lift starts up or down when appropriate button is pressed,

and may be stopped by pressing “Off” button. Factory set limit switches stop lift

automatically when projector is in “Show” position.

Optional Key Operated Switch—If ordered, the standard LVC-S can be replaced

with a second single station, momentary key-operated three position (up/off/down)

switch. Multiple Station Control required for this option. Moves lift from “stored” to

“show” position only.

Optional Infrared or Radio Frequency Remote Control—If ordered, a three-

button transmitter is provided, with “up”, “down”, and “stop” buttons. Unit starts up

or down when appropriate button is pressed, and may be stopped by pressing

“off” button. Factory set limit switches stop unit automatically when projector is in

“show” position. Only controls "show" and "stored" positions.

Optional RS232 Control—For Serial communication an R2D7 Serial

Communications Interface is optionally available.

Low Voltage Trigger—Input provided for Low Voltage

Trigger from projector (see diagram on page 4).

Please Note: Scissor Lift SLX must be installed in accordance with the

requirements of the Local Building Codes, the Canadian Electrical Code (CEC),

CAN/CSA C22.1 and the National Electric Code (NEC), NFPA 70, as required. An

appropriate disconnect device shall be provided as part of the building installation.

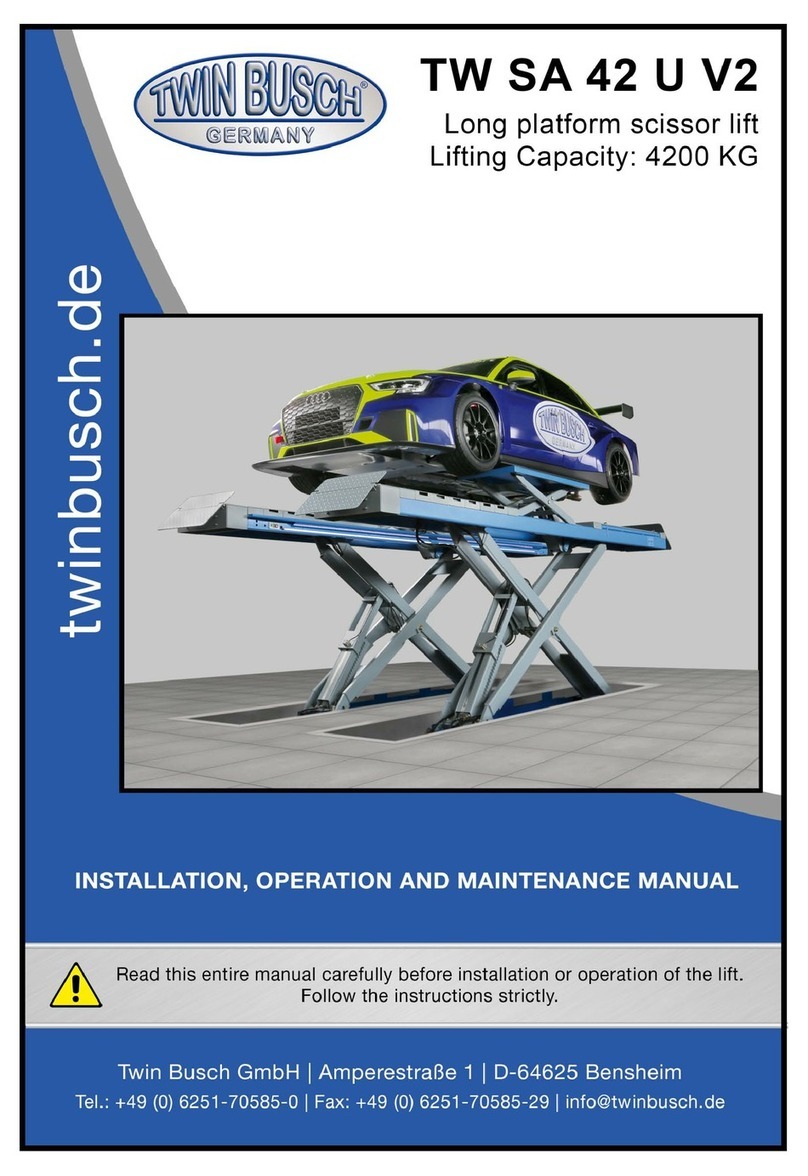

Caution:

Beware of

pinch points

D C U

2¾"

4½"

7/8"

Front Side Back

UP

OFF

DOWN

UP DOWN

OFF

LVC-S SP-KSM

Up & Show Service

Figure 1

Caution:

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions completely before proceeding.

DANGER: To reduce risk of shock:

1Always disconnect power from lift before cleaning.

WARNING–To reduce risk of burns, fires, electric shock or injuries to persons:

2Disconnect power from lift before putting on or taking off parts.

3Use this lift only for its intended use as described in these instructions. Do

not use attachments not recommended by the manufacturer.

4Never operate this lift if it has a damaged cord or plug. If it is not working

properly, call your dealer or the manufacturer for assistance/repair.

5Keep cords away from heated surfaces.

6Never operate lift with air opening blocked. Keep the air openings free of lint,

hair, and the like.

7Never drop or insert any object into any opening.

8Do not use outdoors.

9Route cords and cables as shown in the instructions.

WARNING: Rick of Electric Shock—connect this product to a

properly grounded electrical supply.

IMPORTANT INSTALLATION/OPERATING INSTRUCTIONS

WARNING: To prevent injury, this apparatus must be securely attached to

the building structure in accordance with the instructions.

Test lift prior to installation. Please Note: Packaging must be removed from

lift before testing.

Follow instructions carefully. Installation contrary to instructions invalidates warranty.

Do not obstruct operation of Scissor Lift SLX with fingers or any object.

Serious injury or damage could result.

Lift is intended for use with product weighing not more than 150 kg.

Scissor Lift SLX is designed to accommodate ceiling suspended equipment.

Equipment should not be allowed to rest on optional ceiling closure

during operation (refer to section titled “Installing Projector”).

Entire bottom of unit must be unobstructed to permit proper operation.

Sufficient clearance must be allowed below projector or optional ceiling closure:

305 cm for Model SLX10, 427 cm for Model SLX14, etc

.

Unit must be installed level (use a carpenter’s level).

Unit operates on 230V AC 50 Hz. current. 5.4 amps current draw (2 amps for

lift, 3.5 amps for outlet).

Verify the show position when testing lift. Make required changes by referring

to adjustment instructions on page 4 of this document.

The maintenance/service factory limit setting must not be adjusted to a lower posi-

tion than the preset factory limit setting. In addition, Draper does not recommend set-

ting show position at the maintenance/service position—for example, if you wish to

have 244 cm show position, order a lift with at least a 305 cm maintenance position.

When the Scissor Lift SLX is to be installed in “other space used for environ-

mental air” the optional environmental air space housing must be installed per

instructions to isolate the lift from the “other space used for environmental air.”

CAUTION: Before servicing unit, disconnect hardwired control and any

remote control.

Note: Unit has been thoroughly inspected and tested at factory and found to be

operating properly prior to shipment.

WARNING/AVERTISSEMENT

RISK OF ELECTRIC SHOCK. DO NOT OPEN

RISQUE DE CHOC ELECTRIQUE. NE PAS OUVRIR.

These Installation/Operating Instructions are available in the official language of the

country where you purchase the product. Please contact your distributor to request a copy.

Vous pourriez demander les instructions d’installation et d’opération traduises dans la

langue officielle du pays ou vous achetez le produit. Veuillez demander à votre distributeur.

Die Gebrauchsanweisung für Installation und Konstruktion sind in der offiziellen

Sprache des Landes, indem Sie das Produkt gekauft haben, vorhanden. Fragen Sie die

jeweilige Verkaufs-Abteilung.

cable and should be plugged in to Control Panel on top frame of lift for control of

the "Up" and "Show" positions. Momentary Key Switch shown below comes with

22.8 m of cable and should be plugged in to Control Panel on top frame of lift for

control of the "Service" position.