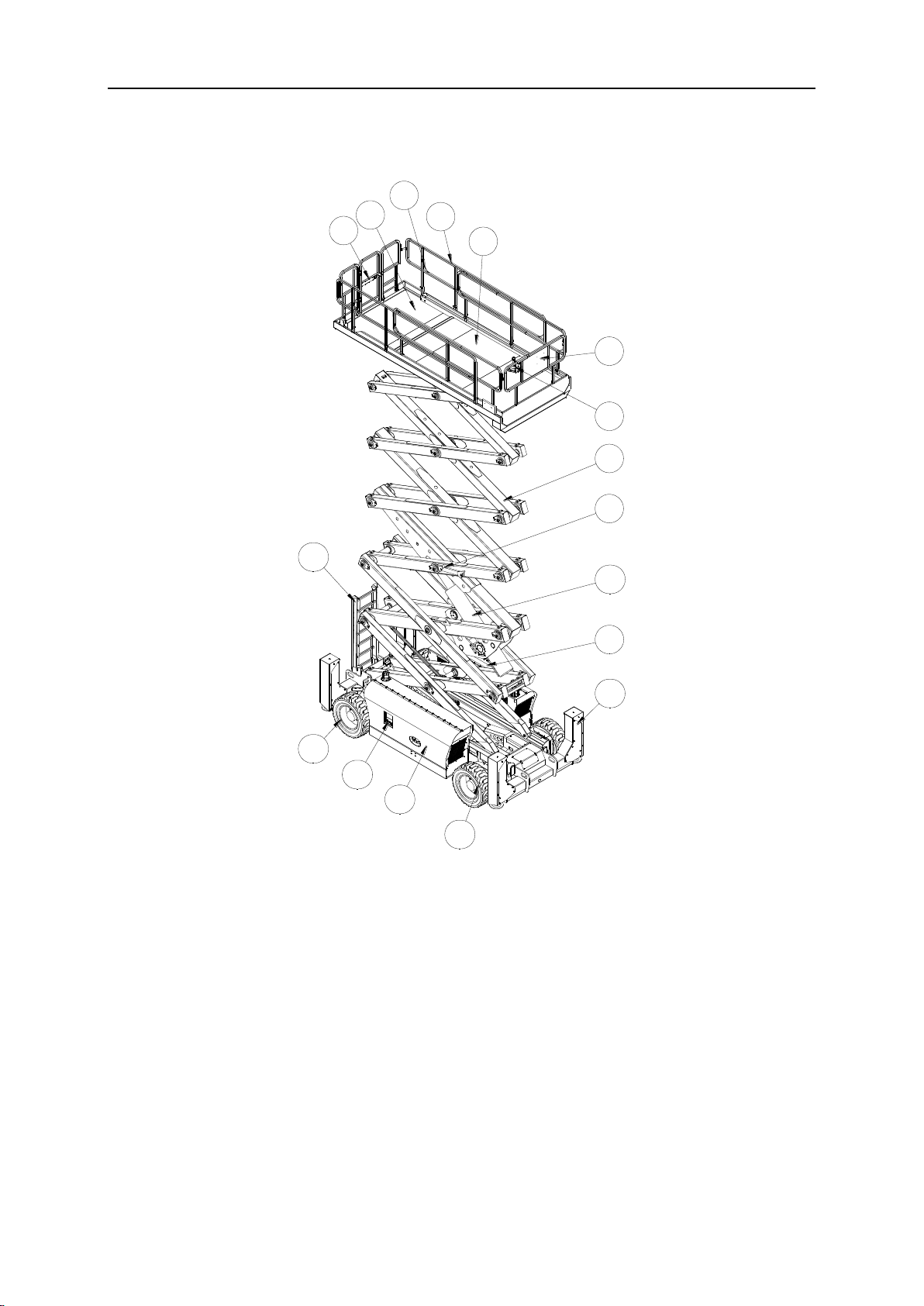

DINGLI JCPT2223RT Setup guide

Table of contents

Other DINGLI Scissor Lift manuals

DINGLI

DINGLI JCPT2223RTB Setup guide

DINGLI

DINGLI E-TECH ACE Series Installation guide

DINGLI

DINGLI JCPT0307 Setup guide

DINGLI

DINGLI S036-RS Setup guide

DINGLI

DINGLI JCPT2212DC Setup guide

DINGLI

DINGLI JCPT DCS Series Installation guide

DINGLI

DINGLI JCPT0808 Setup guide

DINGLI

DINGLI JCPT2223RTA Setup guide

DINGLI

DINGLI SP039-E Setup guide

DINGLI

DINGLI JCPT1523DC Setup guide

Popular Scissor Lift manuals by other brands

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL STRATOS S39 Instruction and maintenance manual

Mec

Mec Crossover Series Operator's manual

Oshkosh Corporation

Oshkosh Corporation JLG RT5394 Operation and safety manual

Rotary

Rotary 000 Series installation instructions

Skyjack

Skyjack SJ6832 RTE Series operating manual

AJ

AJ 31079 operating instructions

Upright

Upright LX31 Operator's manual

RUDETRANS

RUDETRANS RLSS-301 user manual

LGMG

LGMG SS1230E Operation and safety manual

WERTHER INTERNATIONAL

WERTHER INTERNATIONAL SATURNUS 40R Instruction and maintenance manual

Wesco

Wesco LDT-3080 Operating instructions and parts manual

Dannmar

Dannmar DMR-6 Installation and operation manual