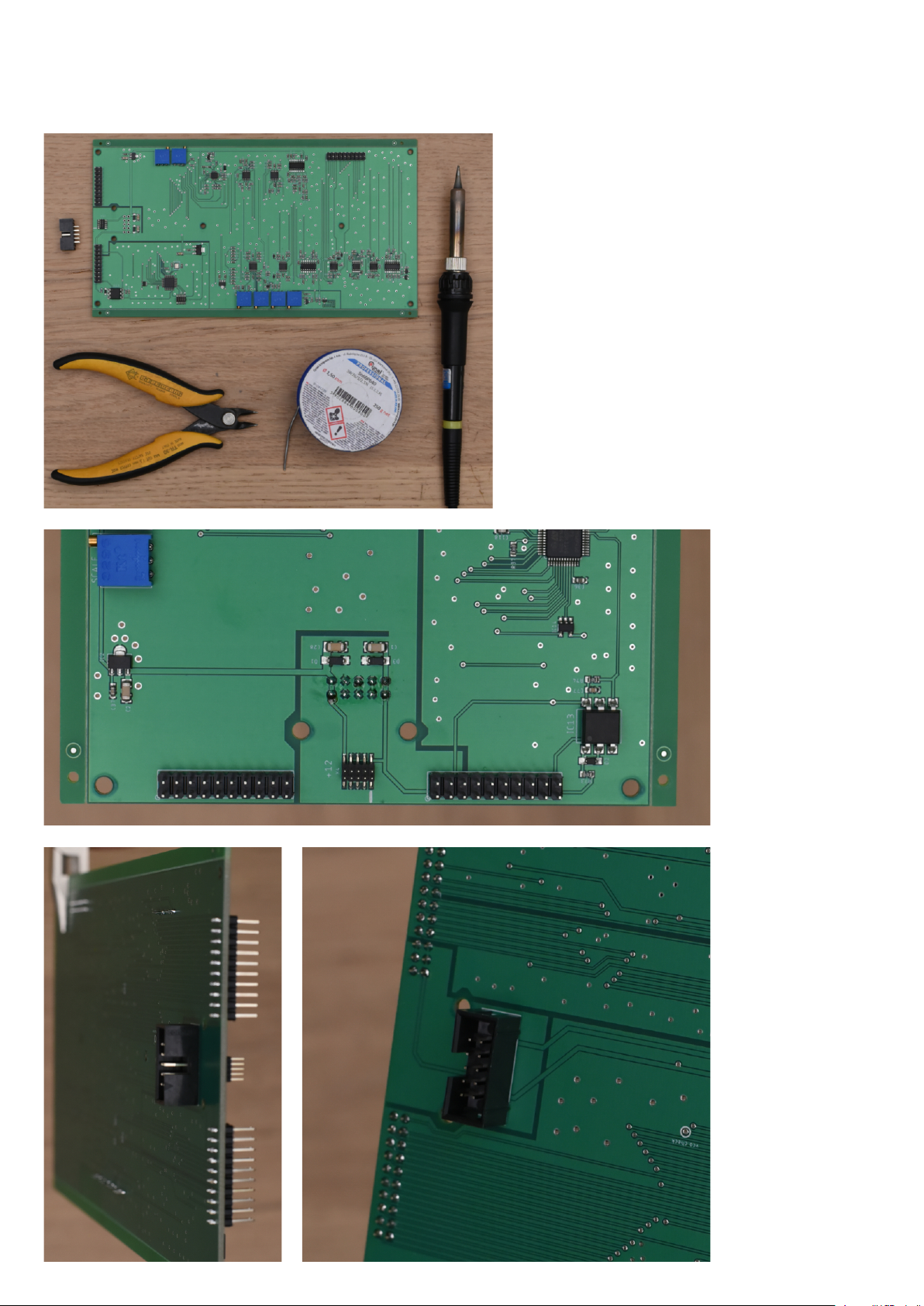

1. Construction

1.1 What's in the box?

In the box you should nd the following items:

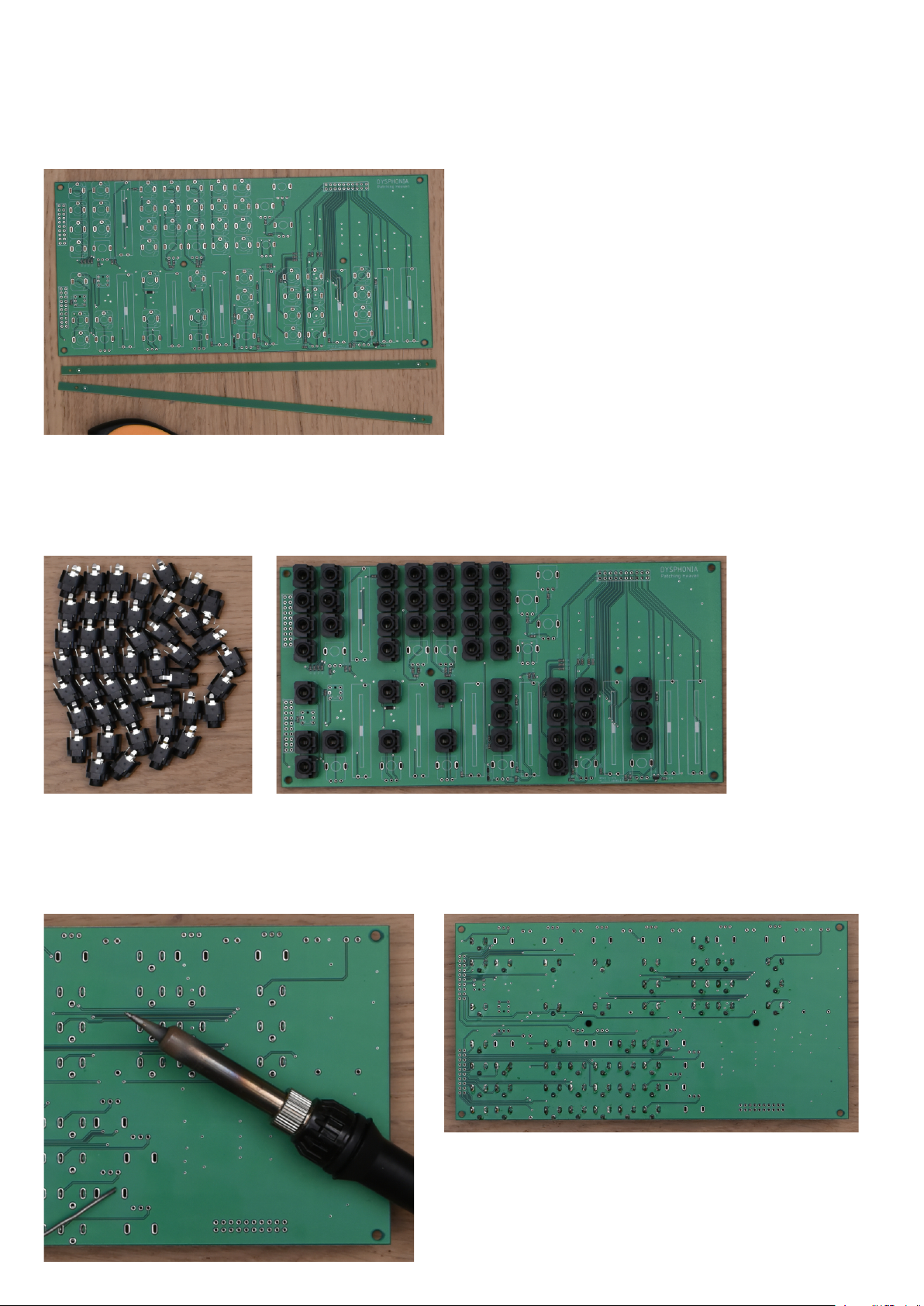

- The Bottom board, which is pre-assembled and tested in-house

(though you will still need to solder the ribbon header and tune it)

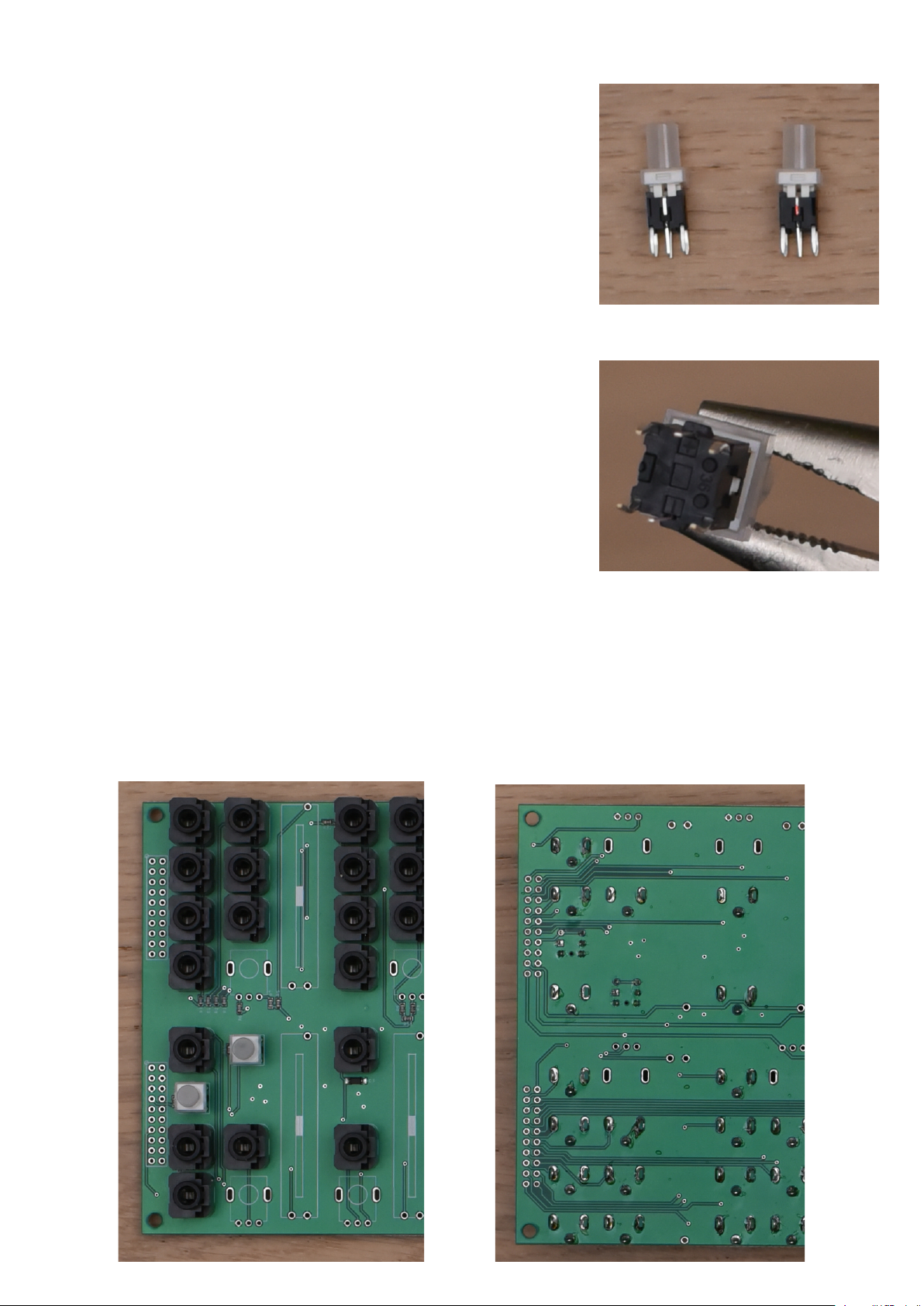

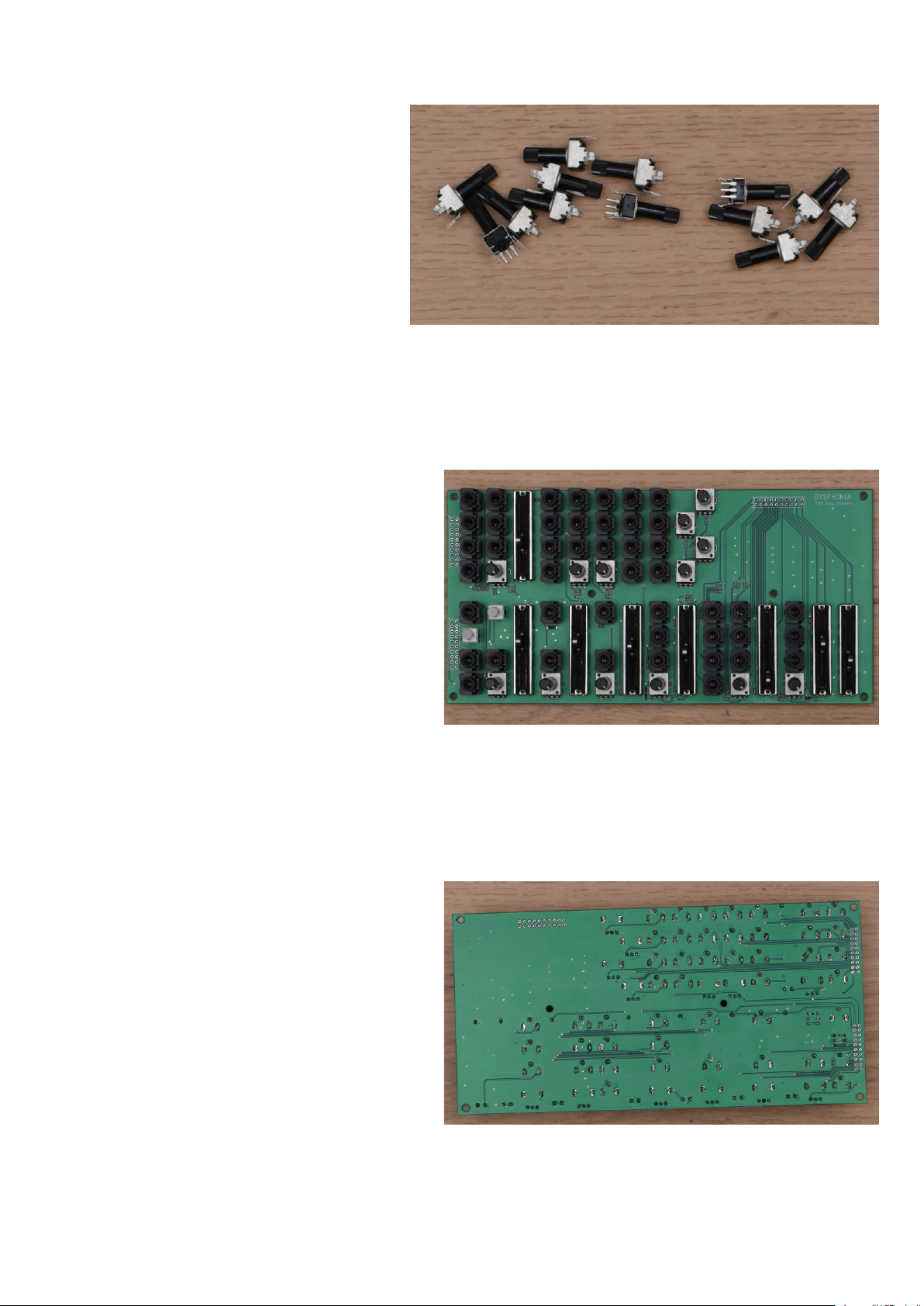

- The Top board

- The aluminum panel

- The power board

- The components bag

- A DIN5 (MIDI) to 3,5mm cable adapter (specs as suggested from MIDI.org)

- A ribbon cable for modular use (not shown in the picture)

BEFORE YOU GET STARTED

Before you start the construction of this DIY project, make sure you have basic soldering skills and that

you can identify the electronic components. If it is your rst time soldering, there are several tutorials

on youtube that can help you :)

It would be easier and helpful for you to work on a big desk, so as to have plenty of space to work on.

Also a room with an open window would be perfect while you soldering.

Before you start the soldering process, make sure you have all the components needed and noted in

the BILL OF MATERIALS SECTION. Please note that we might have added more components than

needed or less (hopefully not). It would be very helpful if you count all the components before starting

the project (but without removing these from their bags).

2