6DRISTEEM GTS HUMIDIFIER INSTALLATION AND OPERATION MANUAL

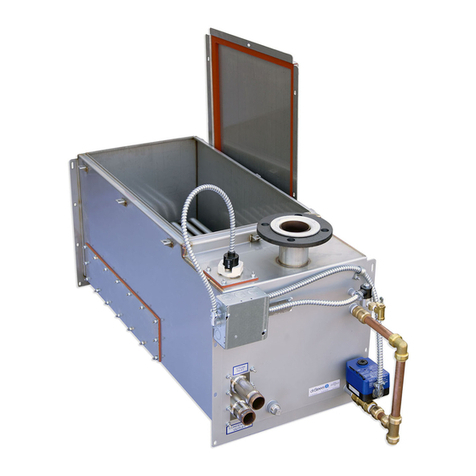

Supply water piping

TAP/SOFTENED WATER

The primary component of the supply water assembly is a solenoid valve,

which may cause noise during fill cycles.

During a fill cycle, cold supply water drops the internal tank temperature and

may collapse the boil, which can cause a low rolling sound. To minimize this,

use hot supply water.

In cases where water hammer occurs when the fill solenoid closes, a shock

arrester is recommended. Reducing the supply water pressure (minimum

172 kPa with fill valve open) or using flexible tubing (rated for 100 °C

minimum continuous operating temperature) may diminish the noise.

The minimum water conductivity for the GTS tap/softened water model

is 30 µS/cm.

RO/DI WATER OPTION

The water level in GTS humidifiers with the RO/DI water option is controlled

with a float valve. For models with the end-of-season drain option, a solenoid

valve is installed prior to the float valve.

When using nonmetallic tubing, DriSteem recommends the installer place a

50-mm water seal/loop in the supply water line to isolate steam during RO/DI

water system maintenance.

DriSteem highly recommends installing a strainer in the supply water line

to prevent clogging of the solenoid valve or float valve orifice. The strainer

prevents particulate from collecting at the solenoid valve seat.

To minimize RO/DI water waste, disconnect factory piping to the water

tempering device and pipe directly to a tap water source.

WARNING

Fire hazard if using tap/softened supply water with RO/DI water option:

If a GTS humidifier with the RO/DI water option is supplied with

tap/softened fill water, the float valve assembly will become clogged,

and particulate will accumulate on the low water cutoff switch (float

switch). This will cause failure of a critical safety circuit and the potential

for a dry tank fire, which can cause severe property damage, severe

personal injury, or death.

SUPPLY WATER FLOW RATES

The rate of supply water flow into the GTS humidifier tank is determined by the

supply water pressure and the inlet valve. See Table 6-2.

mc_071912_1545

SUPPLY WATER GUIDELINES

Supply water quality is an important

component of humidifier reliability and

maintenance.

Examples:

• Corrosive water can decrease the

service life of the humidifier.

• Excessive water hardness can

increase the humidifier maintenance

requirements.

To maximize humidifier service life

and minimize humidifier maintenance,

DriSteem has established guidelines for

supply water See Table 6-1.

Table 6-1:

DriSteem supply water guidelines

Chlorides*

RO or DI water

Softened water

Tap water

* Damage caused by

chloride corrosion is

not covered by your

DriSteem warranty.

< 5 ppm

< 25 ppm

< 50 ppm

Total hardness

Tap water < 500 ppm

pH

RO, DI, or softened

water

Tap water

7 to 8

6.5 to 8.5

Silica < 15 ppm

You may wish to take action to mitigate

potential negative effects to your

humidifier. Supply water outside of these

guidelines may void your DriSteem

warranty. Please contact your DriSteem

distributor if you need advice.

Table 6-2:

Supply water flow rates (liters per minute)

Supply

water

pressure

Solenoid valve flow rates

(tap/softened water)

Float valve flow rates (RO/DI water)

Models 100 – 400 Models 500 – 800

200 kPa 7.2 6.7 17.0

350 kPa 9.0 8.8 22.5

450 kPa 10.2 9.9 25.4

550 kPa 11.1 10.8 27.6