C O N T E N T S

Specifications ................................................................................................................. 6

1.1 General Specifications for the SP2 XR................................................................................... 6

1.2 Electrical Specifications......................................................................................................... 7

1.3 Recommended Maintenance................................................................................................ 7

1.4 Physical Specifications........................................................................................................... 7

General Information....................................................................................................... 8

1.5 Safety Information ................................................................................................................ 9

1.6 Interface Features ............................................................................................................... 10

1.7 Brief Theory of Operation ................................................................................................... 11

Introduction ..................................................................................................................14

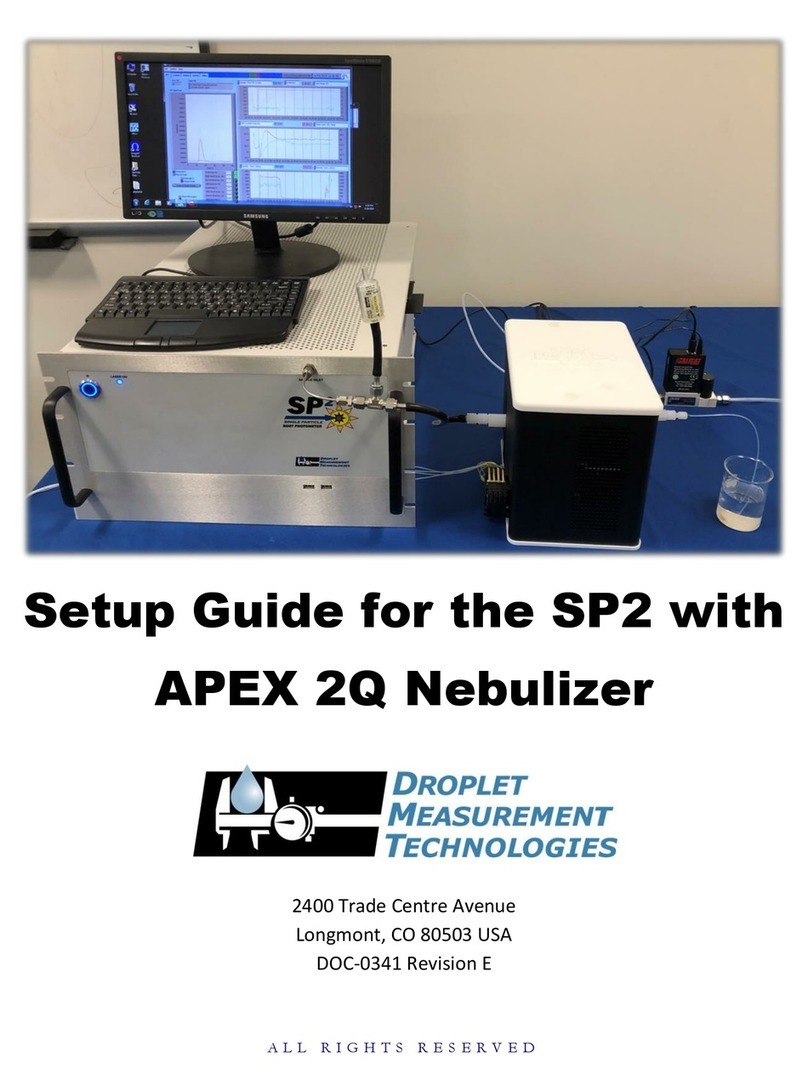

Unpacking, Setup, Installation, and Power Up................................................................18

1.8 Unpacking............................................................................................................................ 18

1.9 Installation........................................................................................................................... 18

1.10 Setup ................................................................................................................................... 18

1.11 Powering the System Down ................................................................................................ 20

SP2-XR Software............................................................................................................21

1.12 Output Data file types ......................................................................................................... 21

1.13 SP2-XR Quick-Start .............................................................................................................. 22

1.14 SP2-XR Main Screen ............................................................................................................ 26

1.15 Histograms Tab.................................................................................................................... 27

1.16 Config Tab............................................................................................................................ 28

Config / Acquisition Tab............................................................................................................... 30

Config / Settings Tab.................................................................................................................... 31

Config / Alarms Tab ..................................................................................................................... 31

Config / Sequences Tab................................................................................................................ 33

Config / Custom Tab .................................................................................................................... 34

1.17 Alarms Tab........................................................................................................................... 35

Examples of how to set parameters for Alarms .......................................................................... 35

1.18 System Settings tab ............................................................................................................. 38

1.19 Utility Window..................................................................................................................... 39

Utility –Data Reader ................................................................................................................... 39

Utility –Log reader ...................................................................................................................... 40

1.20 Status Window .................................................................................................................... 41

Laser Beam Profiler Software.........................................................................................42

1.21 Camera Preparation ............................................................................................................ 42

1.22 Running the software.......................................................................................................... 46