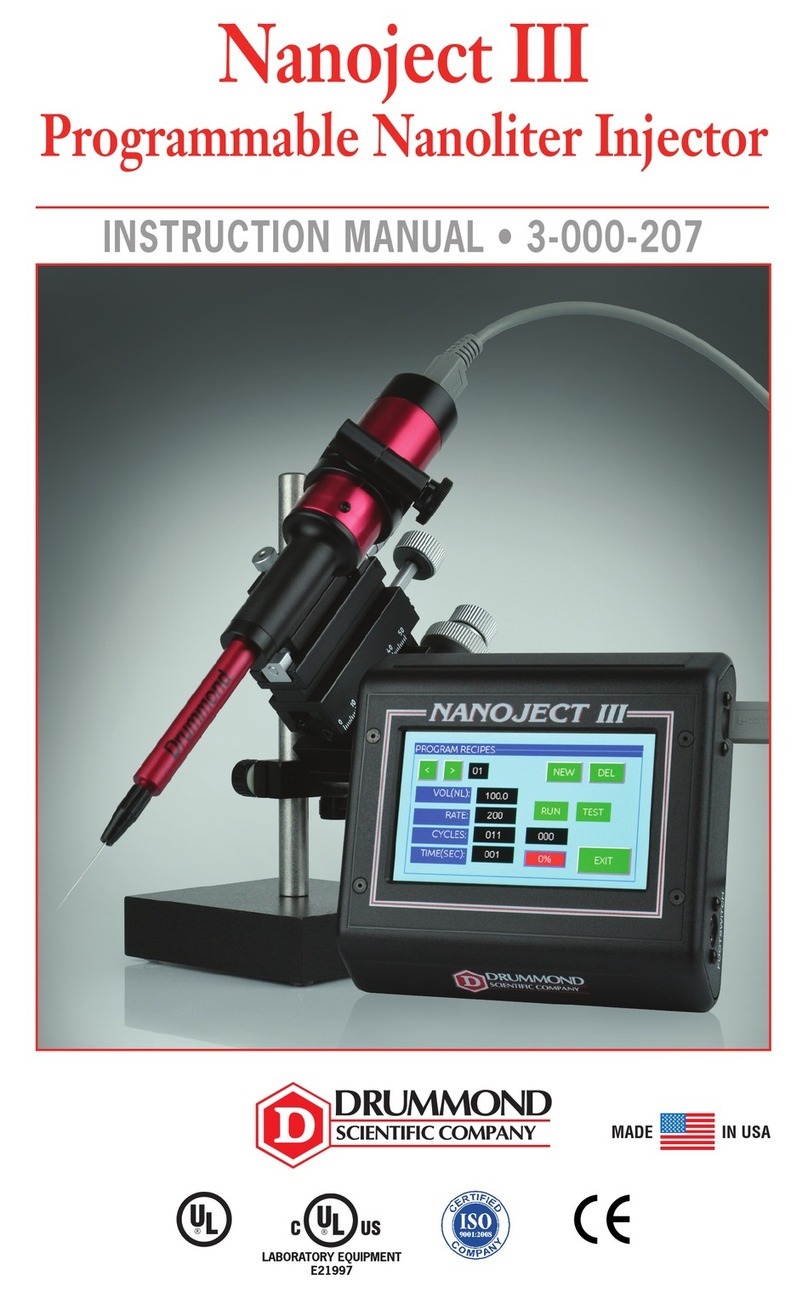

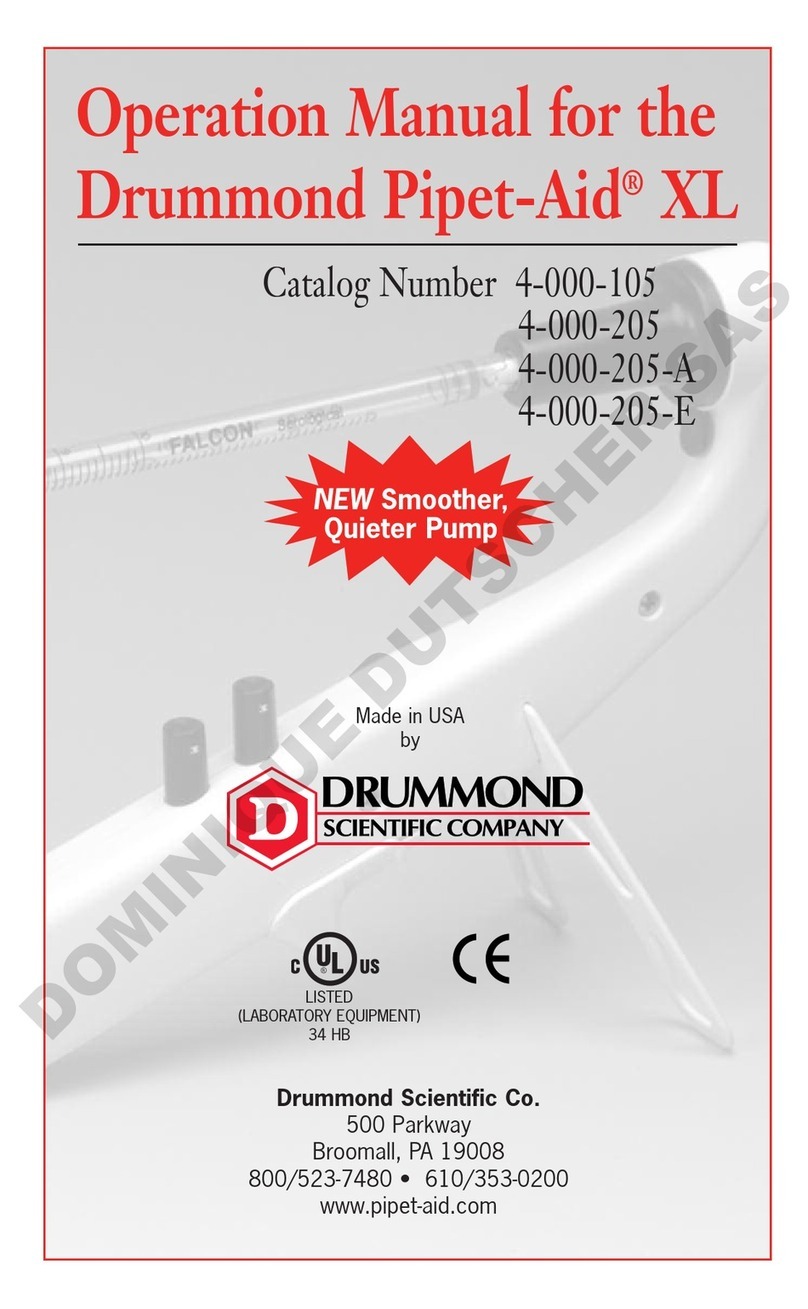

1) Product Specifications

2) Table of Contents

3) Rules for Safe Operation

4) Installation

5) Operation

6) Maintenance

7) Parts/Service

•For Indoor use only.

•Never operate unit in an explosive atmosphere.

The pump motor generates sparks.

•Use extreme caution loading a glass pipet into Pipet-Aid®.

•Expelling liquid from a pipet generates aerosols.

The faster the liquid is expelled, the more aerosols

are generated. Understand the nature of the liquid

being pipetted and take appropriate precautions.

•Do not operate unit with a damaged cord.

•Do not handle power supply with wet hands.

•PIPETTING ACIDS OR STRONG ALKALIS WILL DAMAGE UNIT.

•When servicing, use only identical Drummond

replacement parts.

•Save these instructions.

2 7

The specifications for the Drummond filter are .45 µm for the hydrophilic

layer and .8 µm for the hydrophobic layer. Most competitive pipetting units

use a single layer hydrophobic membrane with ratings of either .22 µm or

.45 µm. These filters protect the handle only. If challenged with an aqueous

solution, the filter will prevent the liquid from entering the handle; however,

it can be subsequently blown out and pipetting can be continued. This

action creates an aerosol generator just above the pipet and all subsequent

dispensing are at risk of being contaminated. While the user may think he

or she is sterilizing the air entering the pipet, they are in fact introducing

contamination.

The most effective safety measure to prevent contamination is the cotton

or fiber plug in each pipet. Even if a sterile filter is installed in a Pipet-Aid,

the first time an aerosol comes in contact with the bottom membrane, the

filter is rendered forever nonsterile. The only thing that prevents this from

happening is the plug in the pipet itself, which prevents aerosols from

leaving the pipet and prevents them from entering. Drummond “self-locking”

TC filters are supplied nonsterile because we believe there is no effective

and practical method to maintain sterility in these devices.

SSeerrvviiccee

Drummond Scientific Company supplies a one year warranty on all Pipet-Aid

Products. Spare parts can be ordered from your favorite laboratory supply

firm, or by calling our toll-free number 1-800/523-7480.

If you have any questions or you need assistance our service department

is available Monday through Friday, from 8:30 AM to 4:30 PM EST.

RReeppllaacceemmeennttPPaarrttss

CCaatt..NNoo..DDeessccrriippttiioonn

4-000-002...............................................................Rubber Insert (2/Pk)

4-000-051...............................................................Replacement Filters (5/Pk)

4-000-057...............................................................TC Gasket (Pair)

4-000-079...............................................................Nosepiece (Black)

4-000-080...............................................................Power Supply, 110 V

4-000-082...............................................................Backing Plate

4-000-083...............................................................Replacement Tape

4-000-084...............................................................Valve Body Assembly

4-000-085...............................................................Coiled Hose

4-000-086...............................................................Hose Support

4-000-087...............................................................Nosepiece Kit

(1 black nosepiece, 4 filters,

TC gasket/pair, & rubber insert)

Model #_______________________

Serial #________________________

Table of Contents

Rules for Safe Operation