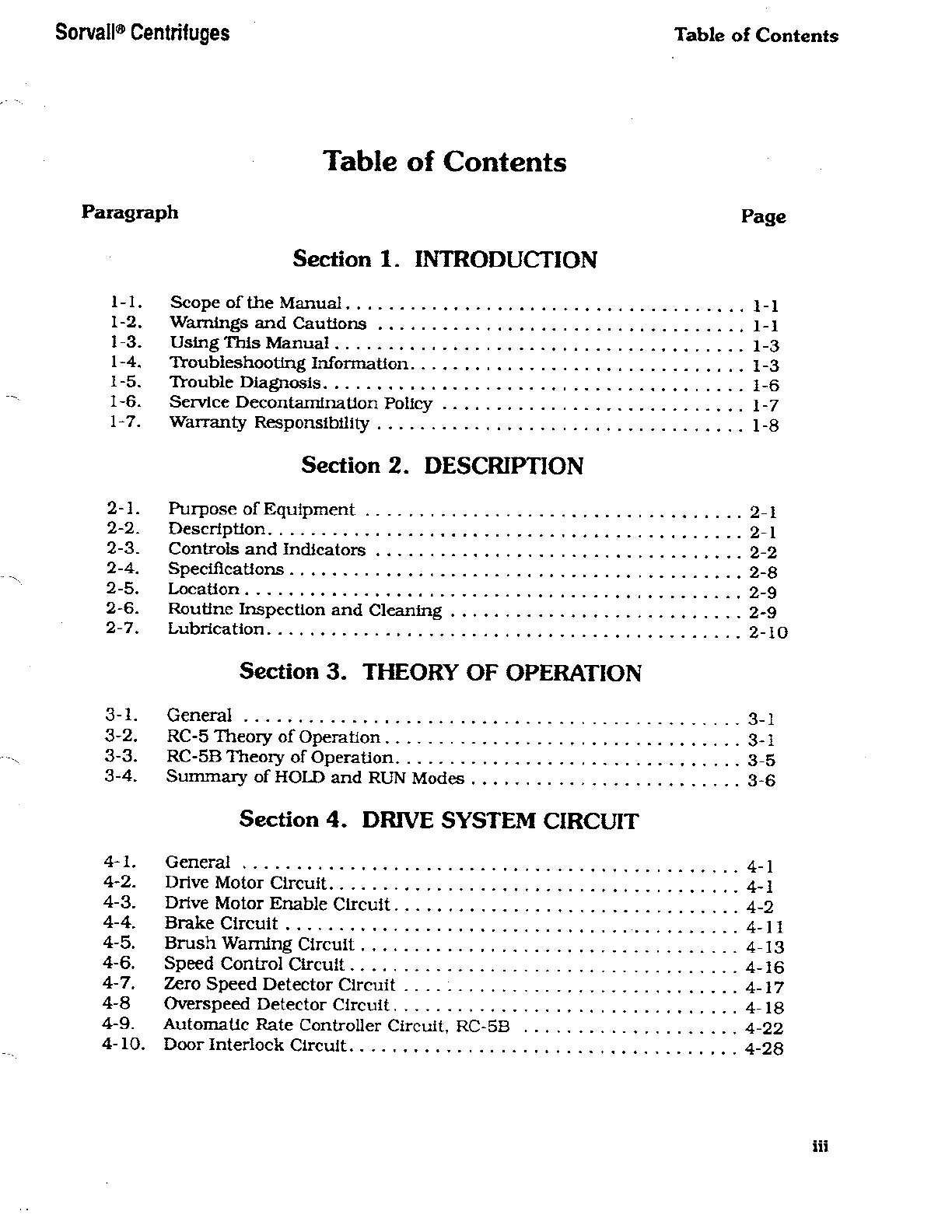

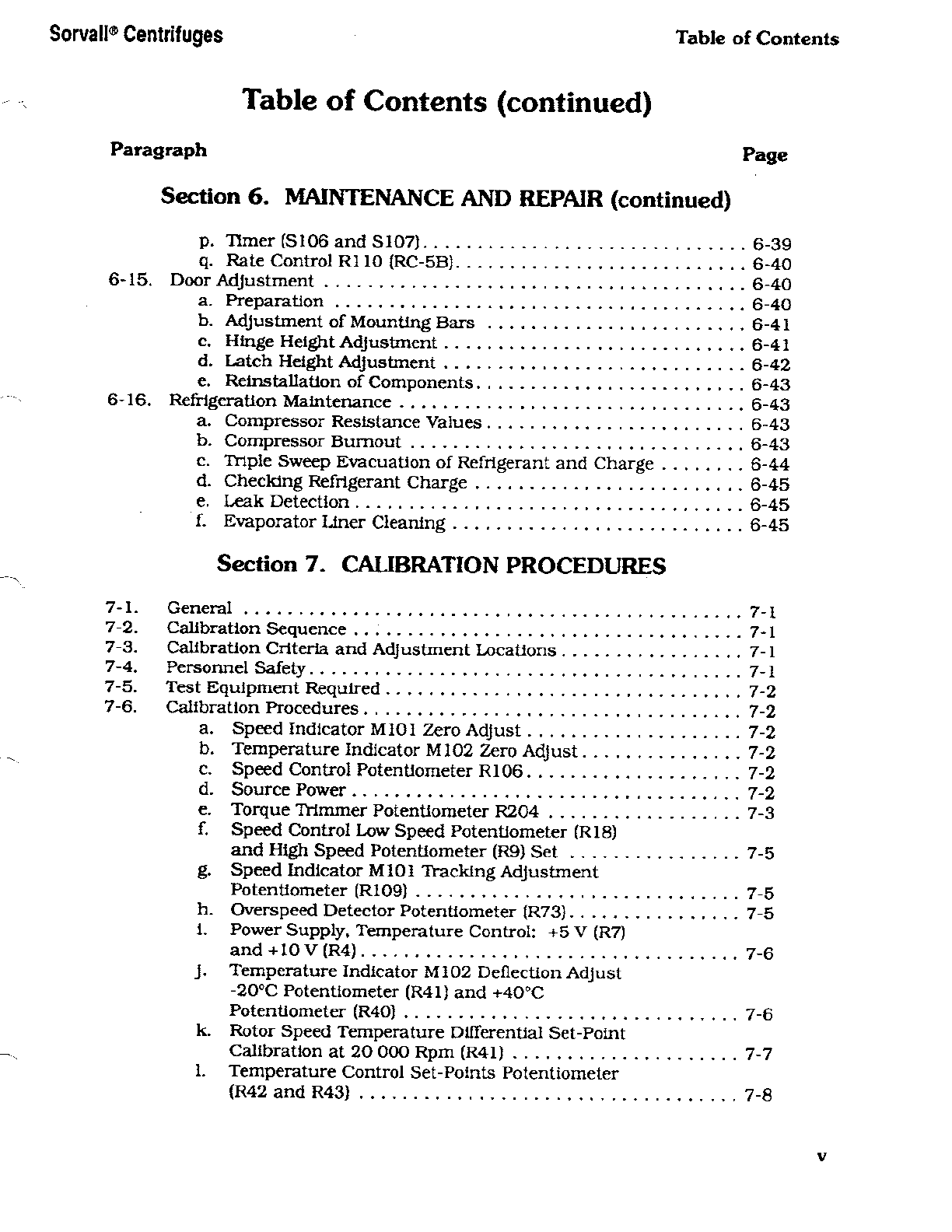

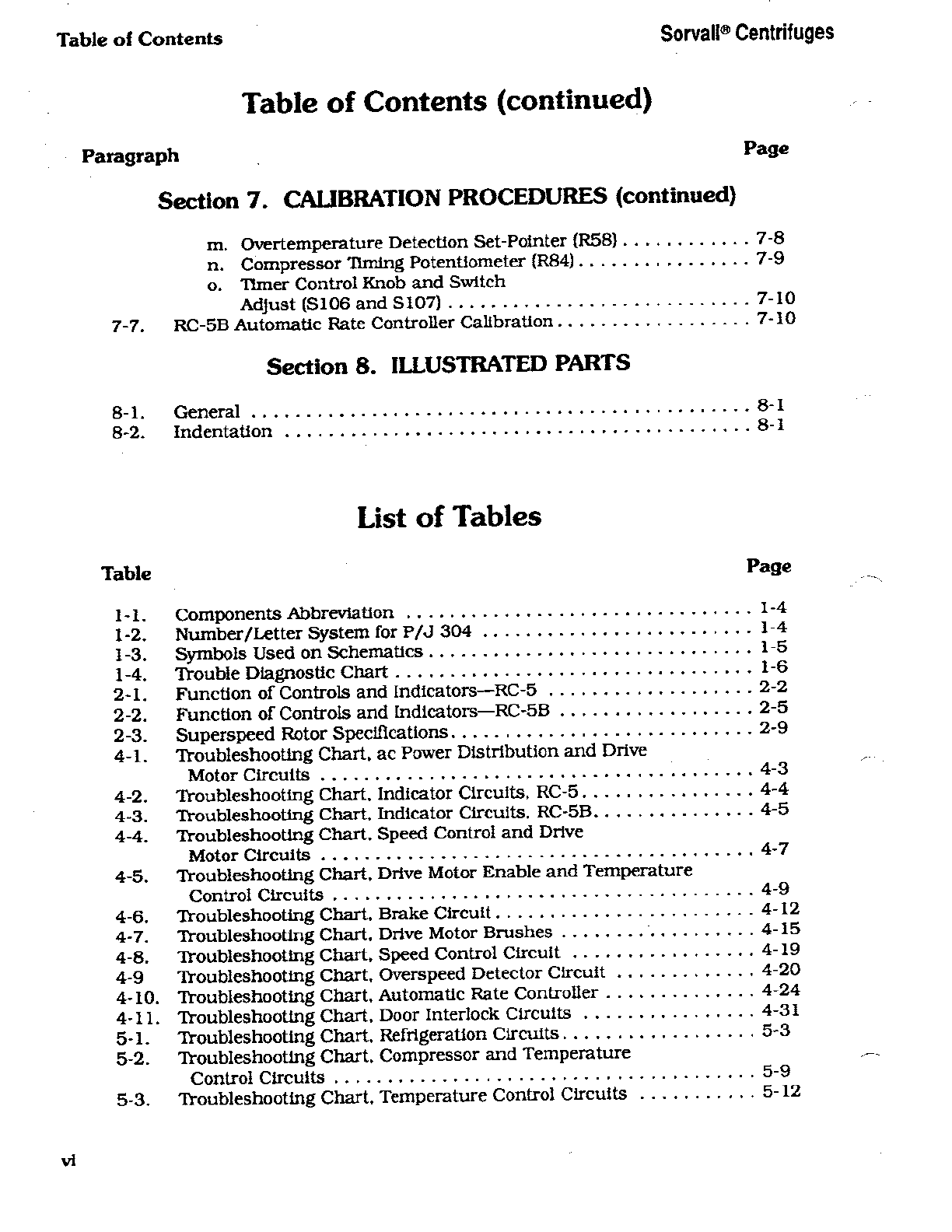

Table of Contents Sorvall®

CentrifugesList

of Illustrations

(continued)Figure

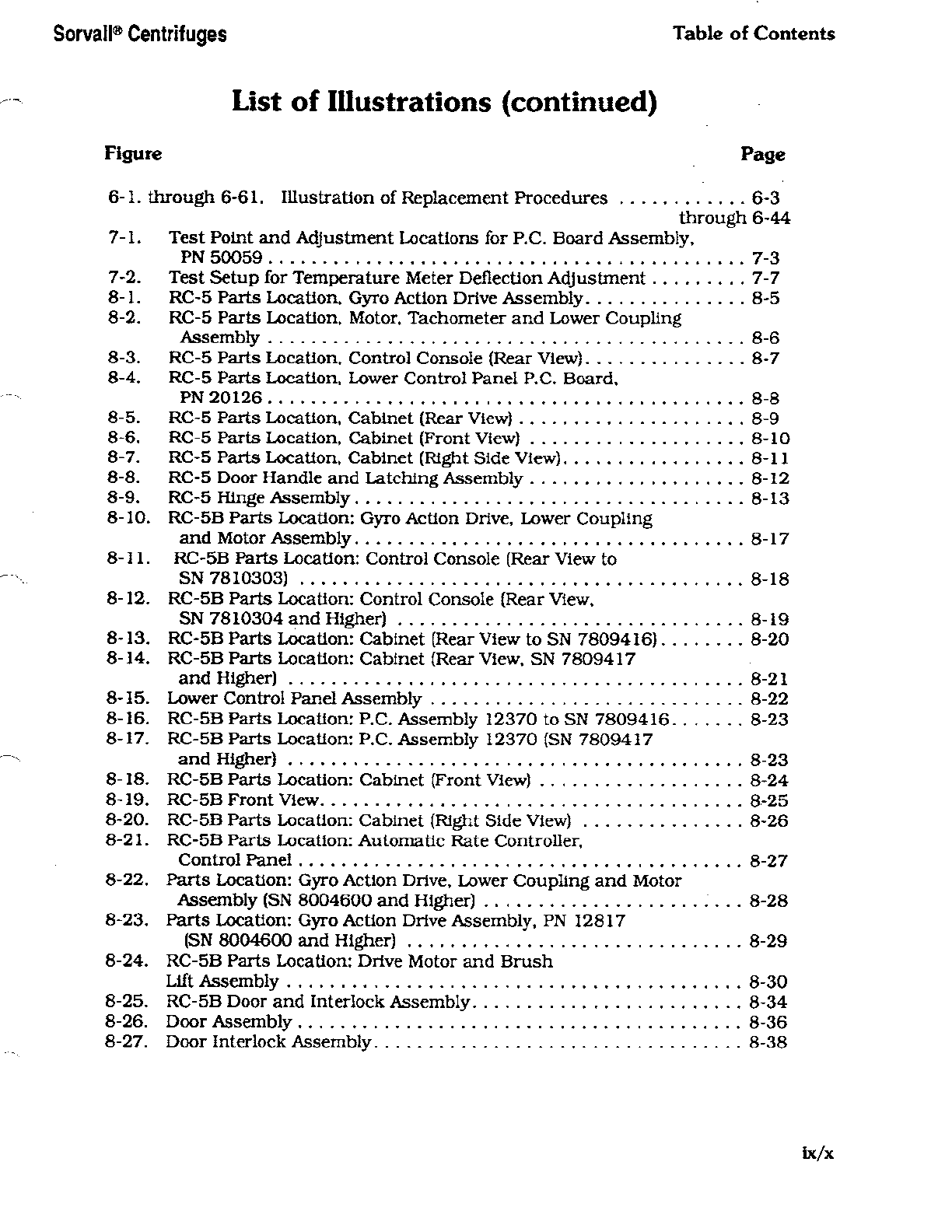

Page3-17.

RC-5B Drive Motor Enable Circuit .......................... 3-283-18.

RC-5B Brush Warning Indicator Circuit ...................... 3-293-19.

RC-5B Door Interlock Indicator Circuit. ...................... 3-293-20.

RC-5B Main Power. ON, Refrigeration and BrakeIndicator

Circuits ...................................... 3-293-21.

RC-5B Tachometer Generator and TachometerDeflection

Circuit....................................... 3-303-22.

RC-5B Drive Motor and Brake Circuit ....................... 3-313-23.

RC-5B Temperature Meter and Set Point Circuit and SpeedControl

Potentiometer .................................. 3-323-24.

RC-5B Compressor Circuit................................ 3-323-25.

RC-5 System Power Distribution Diagram, PN 50035-3 .......... 3-333-26.

RC-5 System Schematic. PN 50031-4 ........................ 3-353-27.

RC-5 Lower Control Panel Wiring Diagram, PN 50041-6 .......... 3-413-28.

RC-5 P.C. Board to Lower Control Panel Wiring Diagram,PN

50039-2 .......................................... 3-433-29.

RC-5/5B P.C. Board Schematic Diagram. PN 20810-9 ........... 3-453-30.

RC-5B System Schematic. PN 50208-10. ..................... 3-513-31.

RC-5B System Schematic, PN 50208-8....................... 3-553-32.

RC-5B System Schematic, PN 50208-2....................... 3-593-33.

RC-5B Lower Control Panel P.C. Board Schematic Diagram,PN

50346-1 .......................................... 3-653-34.

RC-5B Rate Control Schematic Diagram. ..................... 3-673-35.

RC-5B Wiring Diagram. PN 50204-8......................... 3-693-36.

Rate Control System Schematic. PN 50160-8 .................. 3-733-37.

Rate Control Wiring Diagram. PN 50161-4 .................... 3-754-1.

Drive Motor Circuit. Simplified Schematic Diagram ............. 4-14-2.

Drive Motor Enable Circuit, Simplified Schematic Diagram ....... 4-24-3.

Brake Circuit, Simplified Schematic Diagram .................. 4-114-4.

Brush Warning Circuit, Simplified Schematic Diagram........... 4-144-5.

Speed Control Circuit, Simplified Schematic Diagram. ........... 4-164-6.

Zero Speed Detector Circuit. Simplified Schematic Diagram ....... 4-174-7.

Overspeed Detector Circuit. Simplified Schematic Diagram ....... 4-184-8.

Automatic Rate Controller. Block Diagram .................... 4-224-9.

Automatic Rate Controller, Simplified Block Diagram ............ 4-234-10.

Door Interlock Circuit. RC-5. Simplified Schematic Diagram ...... 4-294-11.

Door Interlock Circuit. RC-5B. Simplified Schematic Diagram ..... 4-305-1.

Fluid Circuit of Refrigeration System ........................ 5-15-2.

RC-5 High Torque Motors—3 Terminal Overload-Potential

Relay ........................................ 5-25-3.

Refrigeration Electrical Circuit, Simplified SchematicDiagram

(RC-5B) ...................................... 5-55-4.

Temperature Control Circuit, Block Diagram .................. 5-65-5.

Temperature Control Circuit, Simplified Schematic Diagram ...... 5-75-6.

Overtemperature Detection Circuit, Simplified Block Diagram ..... 5-115-7.

Capacitor Box Wiring Diagram .............................

5-13viii