RC-5B PLUS In~roduction & Description

Section 1: I~TRODUCTIO~ & DESCRIPTIO~

This manual is a service guide for the SORVALL~~~ RC-5B PLUS ~~~~~~~~~~ Refrigerated Centrifuge. It

contains descriptive information, mechanical and electrical theories of operation, maintenance procedures,

calibrations, and an illustrated parts list for ordering replacements.

A IV A ~ ~ I ~ ~

To avoid personal injury, all

replacement and calibration proce¬

dures should be performed by quali¬

fied service personnel.

1-1. Intended Use

This manual is for qualified service personnel who are familiar with

electronics and factory methods for performing repairs, adjust¬

ments, and calibrations. It provides a fault isolation method that

isolates and identifies the cause of a problem within the centrifuge,

a parts list, and information for ordering replacement parts needed

for the repair of parts or systems within the centrifuge.

Warnings, Cautions, and Notes are used throughout this manual to

emphasize important and critical instructions. Service personnel

are expected to be familiar with their meaning (see page ~~~ and to

read them before servicing the centrifuge.

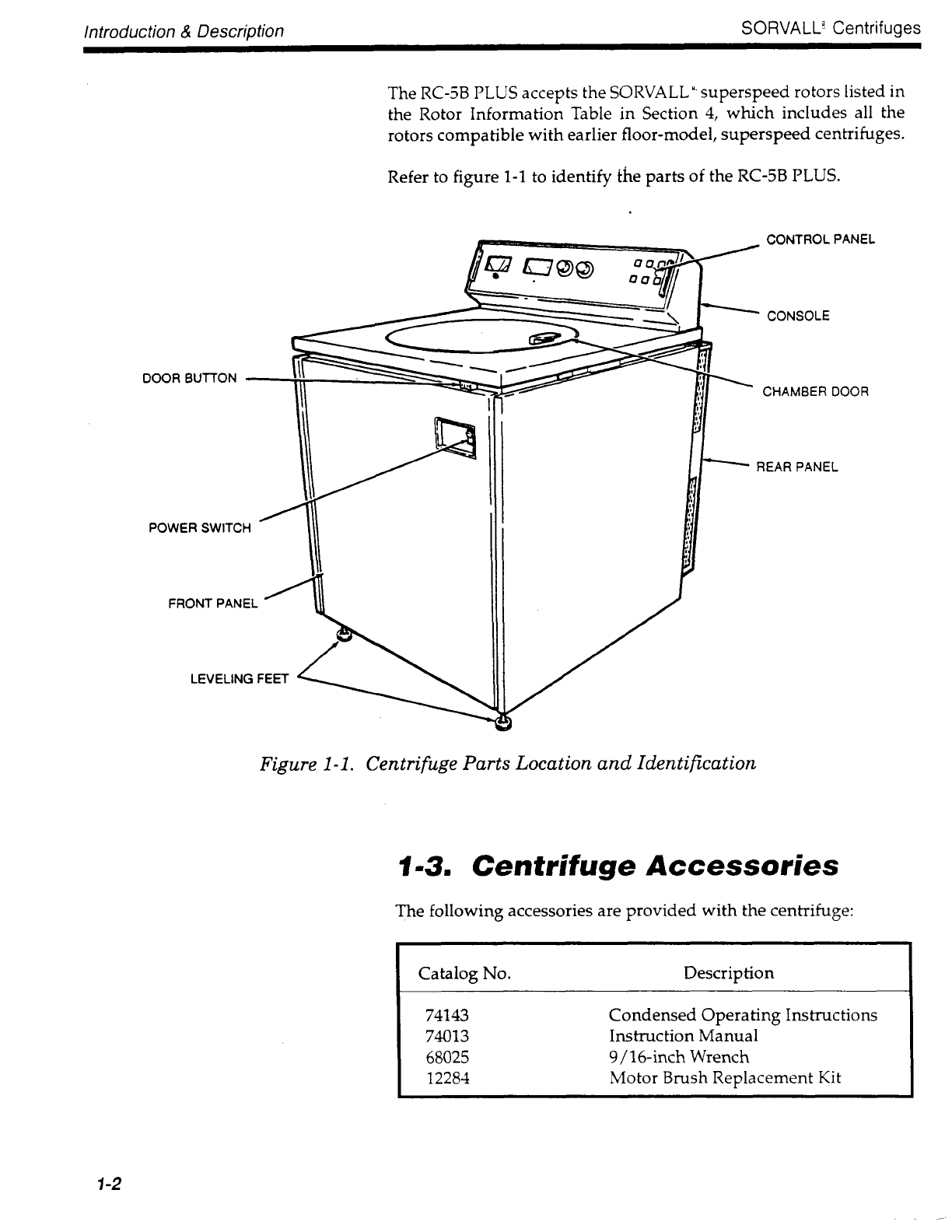

1-2. Centrifuge Description

The RC-5B PLUS is a high-speed (to 21 000 ~~~~~ floor-model

centrifuge used to separate substances of different densities at

controlled temperatures. Its function is to increase the effects of

gravity by centrifugal force to separate substances of different size

or densities at controlled temperatures.

The centrifuge has a fan-cooled motor that is balanced and enclosed

in an air-cooled silencer to ensure smooth, quiet operation over its

full speed range and to promote long life for the brushes and

bearings. The durable motor brushes have increased life and the

gyro-action self-centering drive spindle allows you to balance the

centrifuge tubes by "eye" rather than by weighing them.

The refrigeration system is a low-temperature, hermetically-sealed

unit consisting of a compressor, condenser, evaporator/rotor

chamber and interconnecting tubing. It is charged with SUVA~~~refrigerant,

one of ~~~~~~~~ ~~~~~~~~~~~~~~~ coolants. During

operation, the cooling system will maintain rotor compartment

temperature within 1°C ~~~~~~~~~~~

Run parameters are selected ~~ setting the dials on the front control

panel. Actual run conditions are continuously displayed during

operation by easy-to-read analog displays.