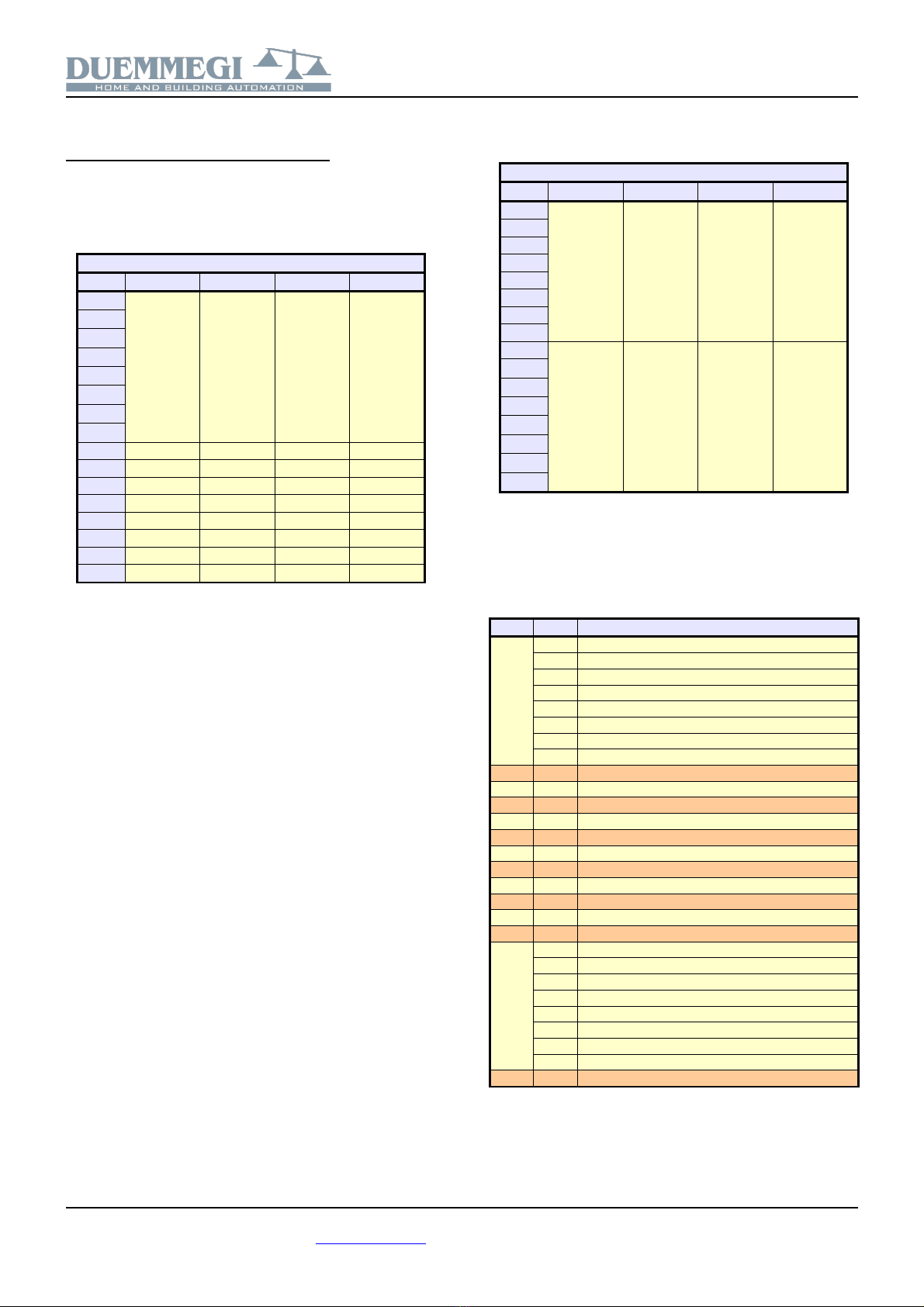

Contatto

Mod4TP/I

T Open: is the time the roller shutter needs to go from the

fully closed to the fully opened position; this time is mea-

sured by the module itself during the calibration procedure

but it can also be manually entered (eg. if the used motor

does not allow the detection of the travel time or to copy

the value from another identical shutter already calibrated)

T Close: is the time the roller shutter needs to go from the

fully opened to the fully closed position; this time is mea-

sured by the module itself during the calibration procedure

but it can also be manually entered (eg. if the used motor

does not allow the detection of the travel time or to copy

the value from another identical shutter already calibrated)

Timeout: maximum time during which the motor is driven

(it must be greater eg. of about ten seconds than the pre-

vious two times); this time too in case of calibration is cal-

culated by the module itself

T Step: is the duration of the driving step (pulse) to the mo-

tor to move the slats; lower this time and the higher the res-

olution in the positioning of the slats (min. 0.01s); a typical

step T Step = 0.05s is suggested

N Step: is the number of steps required to perform a com-

plete movement of the slats

Delay: when sending commands 0x0004 or 0x0008 to the

module the start of the motor is delayed by this value

Pause: the motor stopping time before reversing the move-

ment; follow the specifications of the manufacturer of the

roller shutter

DTSxC: is the dead time expressed as number of steps of

duration T Step each one needed by the slats starting

from the fully opened position to begin to rotate

DTSxO: is the dead time expressed as number of steps of

duration T Step each one needed by the slats starting

from the fully closed position to begin to rotate

DTSh: is the dead time in seconds needed by the shutter

to begin to open when starting from the fully closed position

After making sure that the module has been addressed and

connected to the motors correctly follow the following pro-

cedures depending on whether it is a roller shutter with

slats or not.

Rolling shutter with slats

enter in the Mod4TP configuration window the module

address

execute a reading of the current parameters (Read);

this is necessary in the case some motors have al-

ready been set and thus their configuration must not

be corrupted

select for the desired motor the options Slats=Yes

Auto=Yes PressxAuto=Long Pos.onBus=Shutter

enter for the desired motor T.Step = 0.05s DTSxO =

0 and DTSxC = 0

execute a writing (Program) in order to transfer the en-

tered parameters

move the shutter to a height such that the slats move-

ment can be seen and easily evaluated (use the map

in MCP Ide)

move the shutter until the slats are fully closed (usually

by sending a Close command)

perform a series of opening steps and count the num-

ber of steps required to actually start the movement of

the slats; this number of steps is the parameter DTSx

O (mechanical dead time as number of steps starting

from slats closed). Enter this value in the related text

box of configuration panel

move the shutter until the slats are fully open (usually

by sending an Open command)

perform a series of closing steps and count the num-

ber of steps required to actually start the movement of

the slats; this number of steps is the parameter DTSx

C (mechanical dead time as number of steps starting

from slats opened). Enter this value in the related text

box of configuration panel

execute a writing of the module (Program) in order to

transfer the two newly entered values

move again the shutter until the slats are fully closed

(usually by sending a Close command)

perform one opening step: the motor should be driven

for the time necessary to recover the mechanical dead

time

perform a series of opening steps and count the num-

ber of steps required to move the slats in the com-

pletely opened position; This number of steps is the

parameter N.Step (number of steps required to per-

form a complete movement of the slats). Enter this val-

ue in the related text box of configuration panel

execute a writing of the module (Program) in order to

transfer the parameter just entered

at this point it is possible to perform an automatic cali-

bration that is the measurement of the opening and

closing times; to do this press the button Calib. related

to the desired motor in the configuration window then

wait for the completion of the operation (for details on

the calibration procedure see the related paragraph)

at the end of calibration perform a reading (Read); the

3 parameters T Open T Close. and Timeout in the

configuration window should contain the measured val-

ues for that shutter

complete the parameter setting by entering the desired

values for Delay and Pause (for the latter parameter

the value 0.5s generally goes well)

Rolling shutter without slats

enter in the Mod4TP configuration window the module

address

execute a reading of the current parameters (Read);

this is necessary in the case some motors have al-

ready been set and thus their configuration must not

be corrupted

select for the desired motor the options Slats=No

Auto=Yes PressxAuto=Short Pos.onBus=Shutter

execute a writing (Program) in order to transfer the en-

tered parameters

perform an automatic calibration that is the measure-

ment of the opening and closing times; to do this

press the button Calib. related to the desired motor in

the configuration window then wait for the completion

of the operation (for details on the calibration proce-

dure see the related paragraph)

DUEMMEGI s.r.l. - Via Longhena 4 - 20139 MILANO

Tel. 02/57300377 - Fax 02/55213686 – www.duemmegi.it

Rel.: 1.0 June 2016 Page 4 of 6