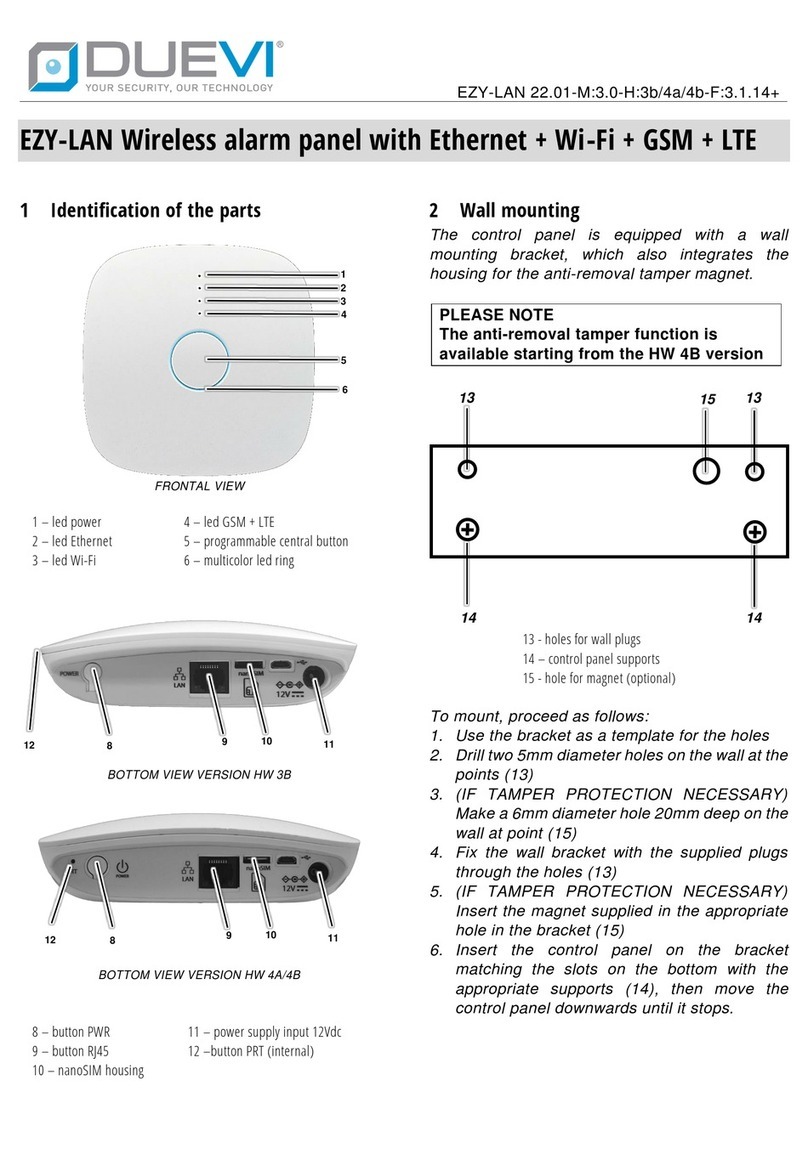

Terminals

AC/AC Anti-masking output N.C.

TM/TM Anti-opening tamper output + bracket anti-removal (in series) N.C.

AL/AL Alarm output N.C.

AB Microwave enabling input.

Apply a positive 9 ÷ 15 VDC voltage to switch o the microwave but

maintain the infrared active (the alarm AL/AL output signals the

detection of infrared element)

- Power supply negative reference

+Power supply positive reference (nominal: 12 VDC)

Wired Dual Technology Detector

Installation and use manual 2021.09-M:1.1-H:SE-03v4-13-F:1.0

DESCRIPTION

Thank you for choosing our dual technology detector for your security system.

DDT-2 is a compact dual-technology movement detector equipped with passive

infrared (PIR) and microwave (MW) detection elements. When both

technologies detect movement or at masking attempts (AM), the alarm starts.

This detector assure to your security system an high-level protection reliability

against intruders and nuisance.

FEATURES

• Detector range: about 12 m

• Microprocessor-based signal analysis

• Anti-masking (AM)

• LEDs dedicated to dierent detections: microwave, infrared, alarm

• Memory and display of anti-masking event

• Memory and display of alarm event

• Anti-tampering protection (Tamper)

• Input for microwave enabling

• 100 Hz neon lights lter

• Low absorption, max 7 mA

• Microwave sensitivity ne adjustment

• Immune to intense electro-magnetic elds

TECHNICAL *

* Specications can vary without notice

Power supply 9 ÷ 15 VDC (nominal: 12 VDC)

Absorption Max: 7 mA @ 12 V (LED o)

Microwave

Pulsed microwave, patch-array type

Working frequency: 24,125 GHz

Excluded by AB input

Infrared Double element passive infrared

Alarm/Anti-mask timing 2 seconds

Outputs:

Alarm

Tamper

Anti-mask

OptoMOS (solid state relay) N.C. **

max 50 VDC / 100 mA

contact impedance: 7 ÷ 16 Ω

** Outputs open in case of power loss

Detection range Min: 2 m - Max: 12 m, 104° @ 25 °C

Installation height 2.3 m (typical)

Speed detection range 0.3 ÷ 3.0 m/s

RFI immunity Mean: 10 V/m

Temperature -20 °C ÷ 50 °C

Humidity 95 % (relative) max

Dimension 112 x 66 x 46 mm

Weight About 90 g

INSTALLATION TIPS

Do not install the detector exposed to direct or

reected sunlight, or towards windows facing

streets (to avoid car ash lightings).

Verify that there are not obstacles (trees, shields,

furniture, etc.) within the detection area, which

can cause masking / false detections.

Avoid to install the sensor faced towards heating

systems and/or conditioning systems causing fast

temperature variations.

Place the sensor at least at 1 meter far from the

nearest uorescent light source to avoid

interference with the microwave element.

DESCRIPTION

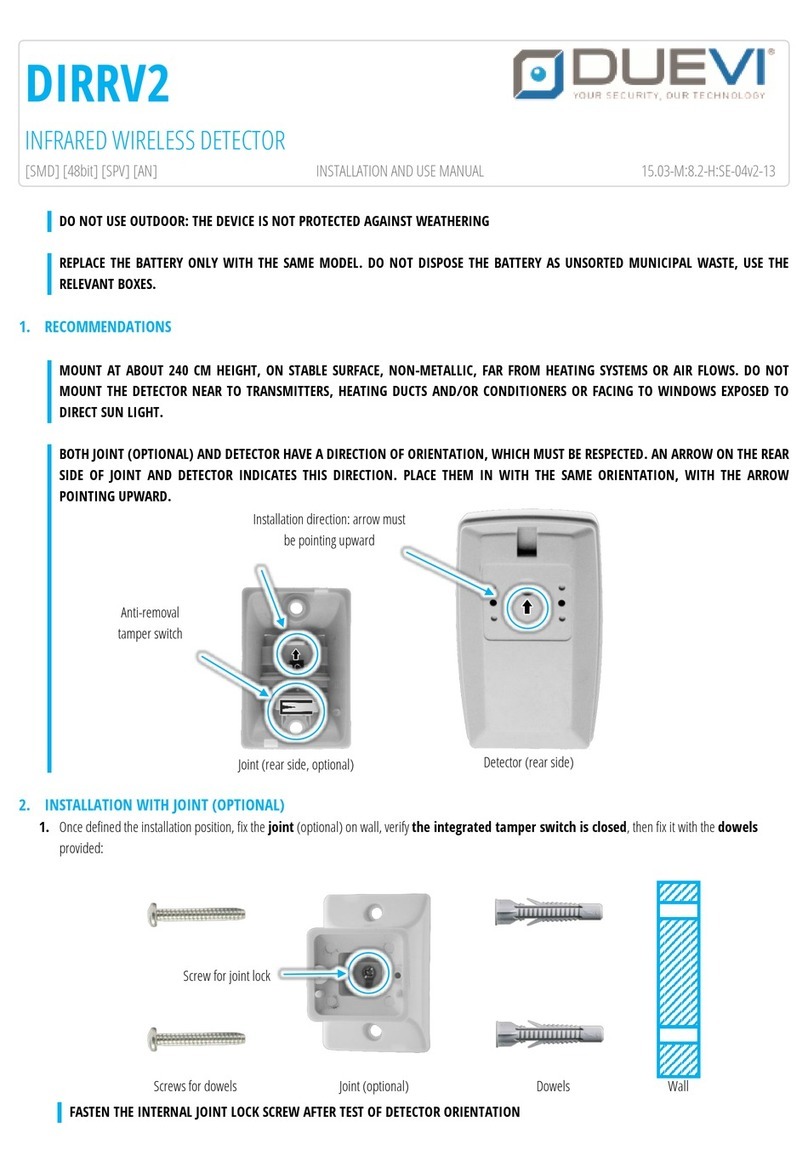

Bracket tamper Terminals

MW status LED IR status LED

DIP-SWITCH

DIP1:LED

DIP2:ANTIMASK

MW sensitivity

Infrared

DDT-2

Cover tamper

Microwave

Range adjustment:

• “0” = 12m

• “-3” = 12m +20%

• “+3” = 12m - 20%

Disabling jumper:

J.TCO (cover)

J.TBR (bracket)

Alarm

status LED

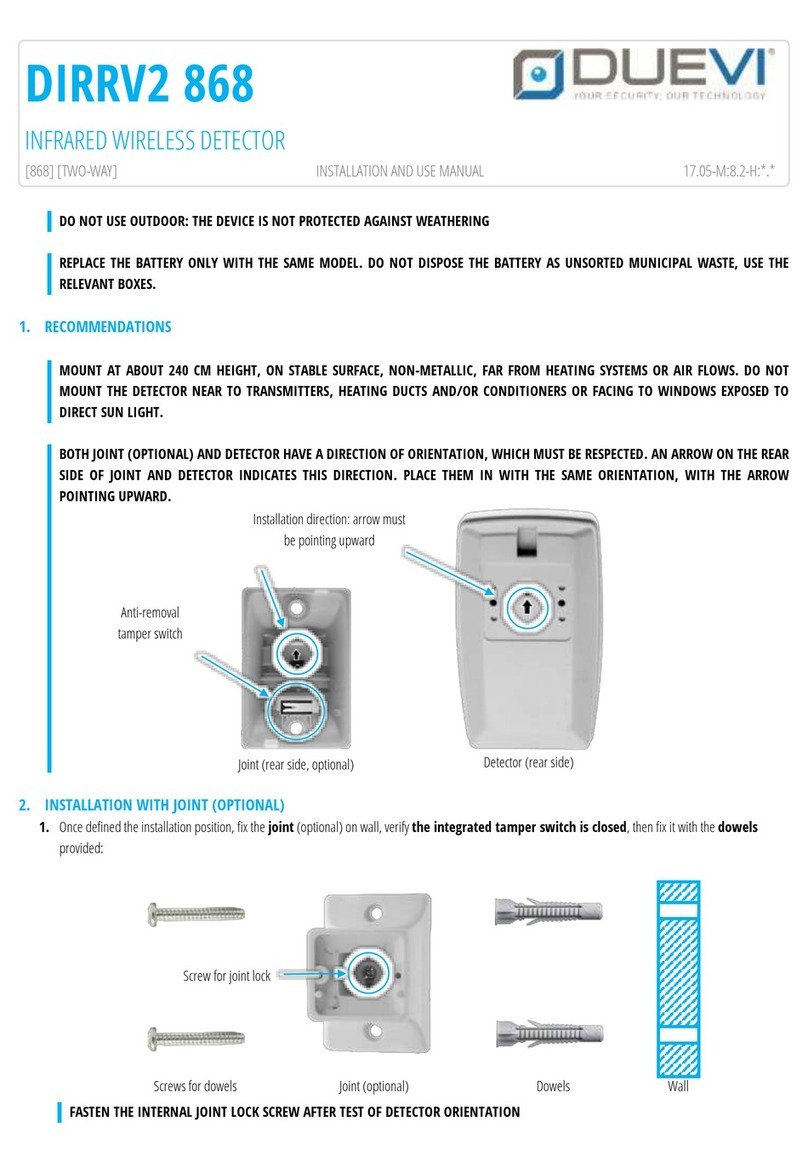

JUMPERS

JUMPERS ON OFF

J.TCO (Cover tamper) Tamper disabled Tamper enabled

J.TBR (Bracket tamper) Tamper disabled Tamper enabled

DIP-SWITCH

DIP ON OFF

DIP1 (LED) LED enabled LED disabled

DIP2 (ANTI-MASKING) ANTI-MASK enabled ANTI-MASK disabled