Duke WB302-NAT User manual

This manual is Copyright 2011 Duke Manufacturing Company. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Company.

Duke Manufacturing Company

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

Please read this manual completely before attempting to

install, operate or service this equipment

Service Manual

GAS OPERATED

WETBATH

FOODWARMERS

MODELS

WB302-NAT WB302-LP

WB303-NAT WB303-LP

WB304-NAT WB304-LP

WB305-NAT WB305-LP

P/N 219218B

Gas Operated Foodwarmers

2

IMPORTANT WARNING AND SAFETY INFORMATION

WARNING

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR PERFORM-

ING MAINTENANCE ON THE EQUIPMENT.

WARNING

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

WARNING

DO NOT USE OR STORE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT PROPERLY PLACING AND SECURING

ALL COVER AND ACCESS PANELS.

CAUTION

Observe the following:

• Provide and maintain adequate minimum clearances from all walls and combustible materials.

• Provide and maintain adequate clearance for air openings.

• Keep the equipment area free and clear of combustible material.

• Operate equipment only on the type of electricity indicated on the specication plate.

• Retain this manual for future reference.

3

Gas Operated Foodwarmers

TABLE OF CONTENTS

SPECIFICATIONS ...............................................................................................................................4

INSTALLATION ...................................................................................................................................4

Location ...............................................................................................................................4

Leveling ...............................................................................................................................4

Stabilizing ............................................................................................................................4

Gas Connection ...................................................................................................................4

MAINTENANCE ..................................................................................................................................5

Stainless Steel Care and Cleaning ......................................................................................5

Gas Regulators ....................................................................................................................5

SERVICE INFORMATION / TROUBLESHOOTING ............................................................................6

PARTS REPLACEMENT .....................................................................................................................7

Gas Valve Replacement ..............................................................................................................7

Safety Valve Replacement...........................................................................................................8

Thermocouple Replacement .......................................................................................................8

Pilot Replacement .......................................................................................................................9

Direct Burn Pilot ...................................................................................................................9

Safety Valve Pilot .................................................................................................................9

Burner Replacement ..................................................................................................................10

Direct-Burn Burner .............................................................................................................10

Safety Valve Burner ...........................................................................................................10

Gas Operated Foodwarmers

4

INSTALLATION

Location

The unit represented in this manual is intended for

indoor use only. Be sure the chosen location has

a oor strong enough to support the total weight

of the unit . Reinforce the oor if necessary to

provide for maximum loading. For the most efcient

operation, be sure to provide good air circulation

inside and out.

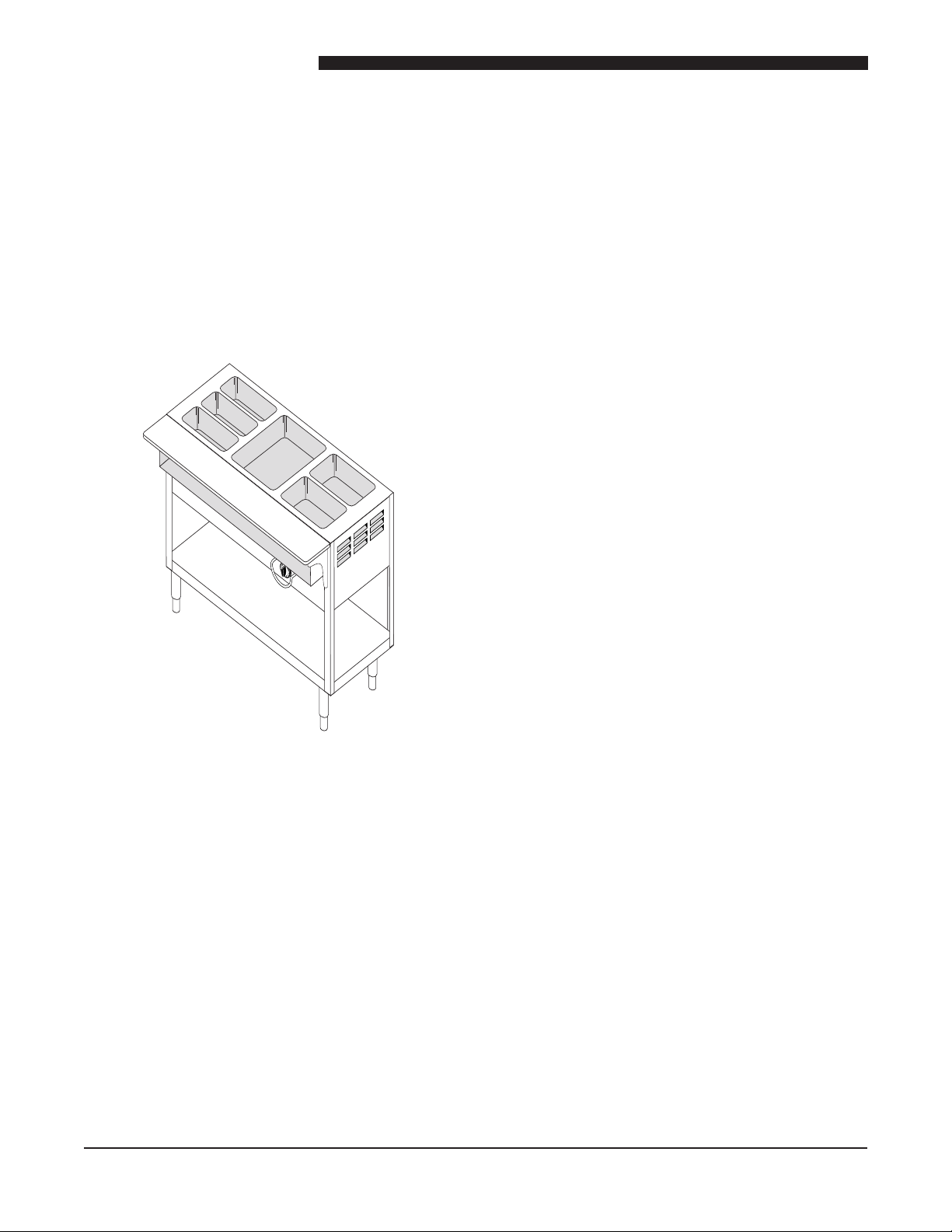

Figure 1.

Gas Foodwarmer

Leveling

Be sure that the units are placed on a rm, at

surface/oor. Check for cracks in ooring or tile

and avoid these areas if possible. If necessary

place support pads, properly rated for the weight

of the unit, to “bridge” uneven or cracked ooring.

Level the unit accordingly.

Stabilizing

Use the leg adjustments to insure that the unit

is solid to the oor surface at all contact points.

Insure that the unit does not “rock” when pressure

is applied to the top corners.

Gas Connection

Gas food warmers are available for natural gas

and propane. All gas connections service must be

performed by a certied plumber and must comply

with local codes.

5

Gas Operated Foodwarmers

MAINTENANCE

Stainless Steel Care and Cleaning

Stainless steel contains 70-80% iron, which will rust.

It also contains 12-30% chromium, which forms an

invisible passive lm over the steel surface and acts

as a shield against corrosion. As long as the protective

lm remains intact, the metal will not corrode.

However, if the lm is broken or contaminated,

outside elements can begin to breakdown the steel

and begin to form rust or discoloration. To prevent

rust and discoloration on stainless steel, several

important steps need to be taken.

CAUTION: Never use steel wool pads or wire

brushes or scrapers.

Avoid cleaning solutions that

contain alkaline or chloride.

Use alkaline based or non-chloride cleaning

solutions. Anything containing chloride will damage

the protective lm on stainless steel. Chlorides

are found in household and industrial cleaners

and also in hard water and salts. If a chloride or

alkaline cleaner has been used, rinse repeatedly

and dry thoroughly.

Always use only soft cloths or plastic scouring pads.

For routine cleaning, use warm soapy water. For

stubborn stains use a non-abrasive cleanser. For

heavy grease use a degreaser. For best results,

rub with the grain of the steel.

Pitting and cracking are early signs of stainless

steel breakdown. But special stainless steel

cleaners can restore and preserve the protective

lm. If signs of breakdown appear, thoroughly clean

and dry all surfaces. Begin regular application of

a high quality stainless steel cleaner according to

the manufacturer’s instructions. Again, always rub

with the grain of the steel for best results.

CAUTION: Never use an acid-based

cleanser! Be sure to clean

all food products from any

stainless surface. Many food

products contain acid, which can

deteriorate the nish. Common

foods include tomatoes, peppers

and other vegetables.

WARNING

THE GAS SUPPLY MUST BE TURNED

OFF AND DISCONNECTED AT ALL

TIMES DURING MAINTENANCE OR

REPAIR FUNCTIONS.

Gas Regulators

Figure 2.

Typical Gas Regulator

A regulator (see Figure 2) is a device for maintaining

a constant safe, operating pressure between a gas

source and a gas appliance. A regulator works

independently of supply pressure and ow.

Installation, service and repair of gas regulators

must be performed by qualified, certified

maintenance personnel.

The Vent Limiting Device is standard on the

regulators. The vent limiter limits gas levels to

within the ANSI safe standard level in the event

of a gas leak. It is absolutely necessary to provide

and maintain free airow around the vent limiter.

Gas Operated Foodwarmers

6

SYMPTOM

Cabinet too cold

Cabinet too warm

Water in bottom of unit

CAUSE

Unit won’t light

Unit won’t light

Pilot light won’t stay lit

Flame set too high

Drain hose plugged

Drain hose loose or disconnected from

drain pan

REMEDY

Turn gas on (Direct burn units)

Light pilot light

Replace thermocouple (Safety valve units)

Adjust pilot ame (Direct burn units)

Turn gas valve down

Clear drain hose

Tighten or connect drain hose.

TROUBLESHOOTING

7

Gas Operated Foodwarmers

PARTS REPLACEMENT

Gas Valve Replacement.

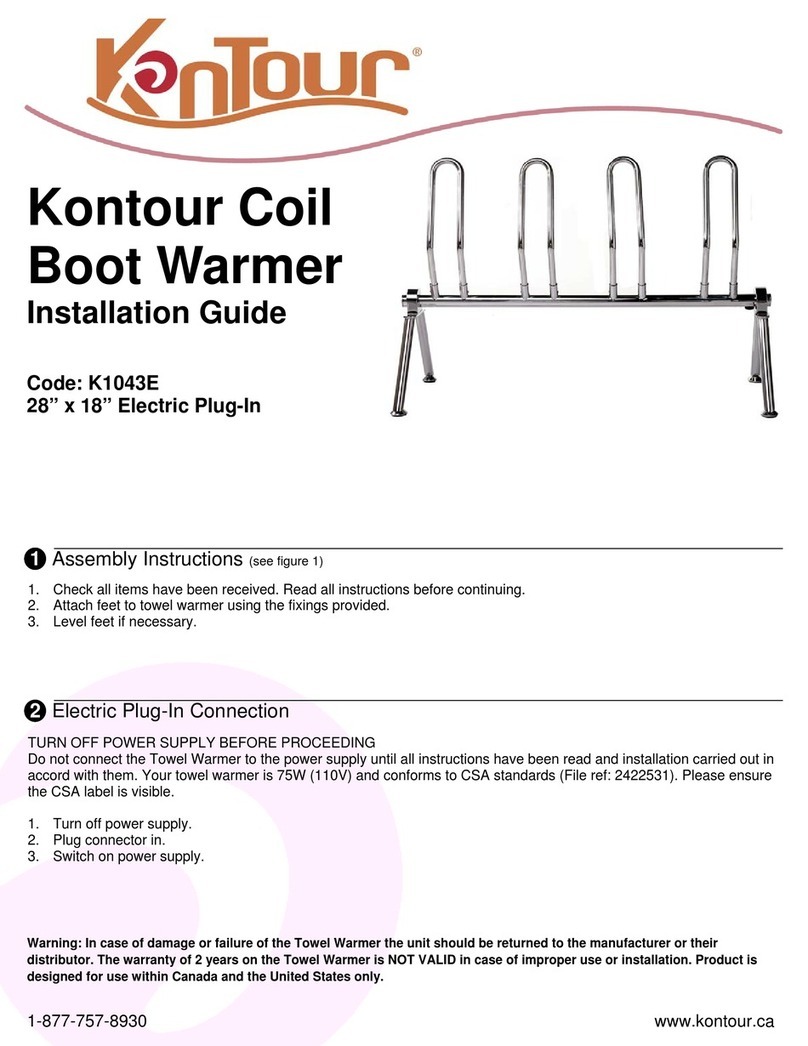

Figure 3.

Location of gas valves

General

The gas valve is located in front on the control

panel below each pan (see Figure 3).

1. Shut the gas supply to the unit off.

2. Remove the galvanized burner liner.

3. Remove the knob.

4. Remove the mounting screws.

5. Disconnect the burner tube from the valve.

CAUTION: Do not kink the burner tube when

moving it out of the way.

6. Remove the valve from the manifold.

7. Place gas rated thread sealer on new valve

threads.

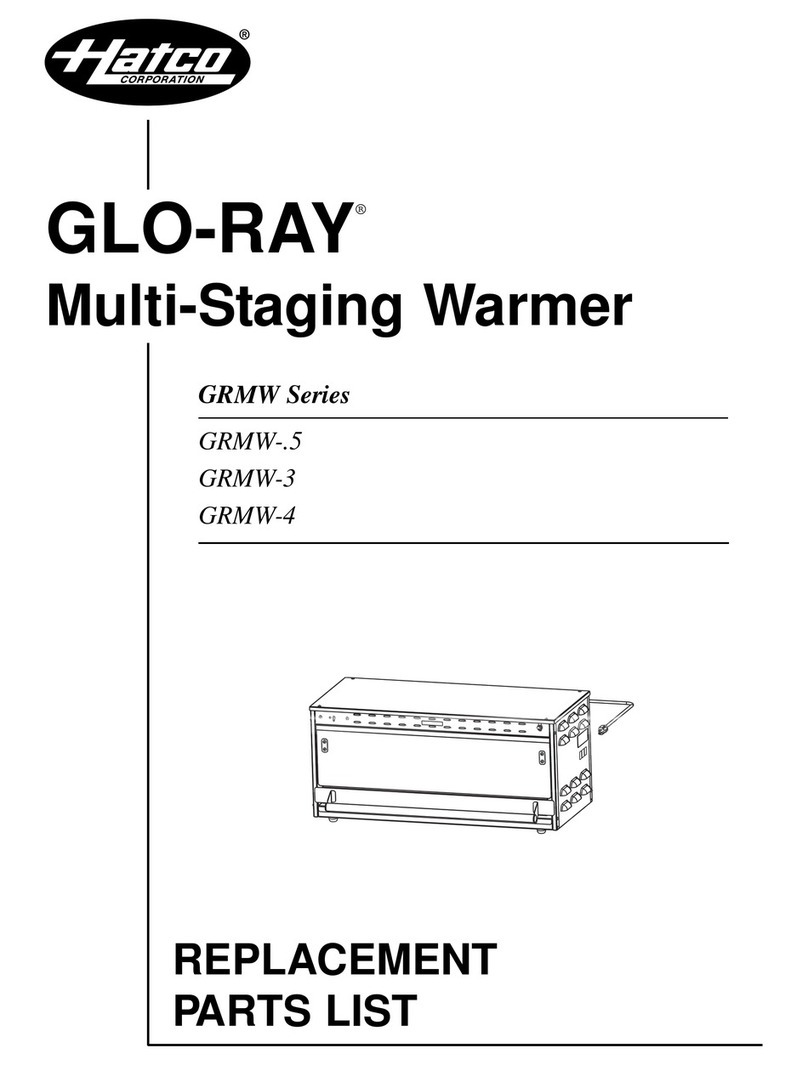

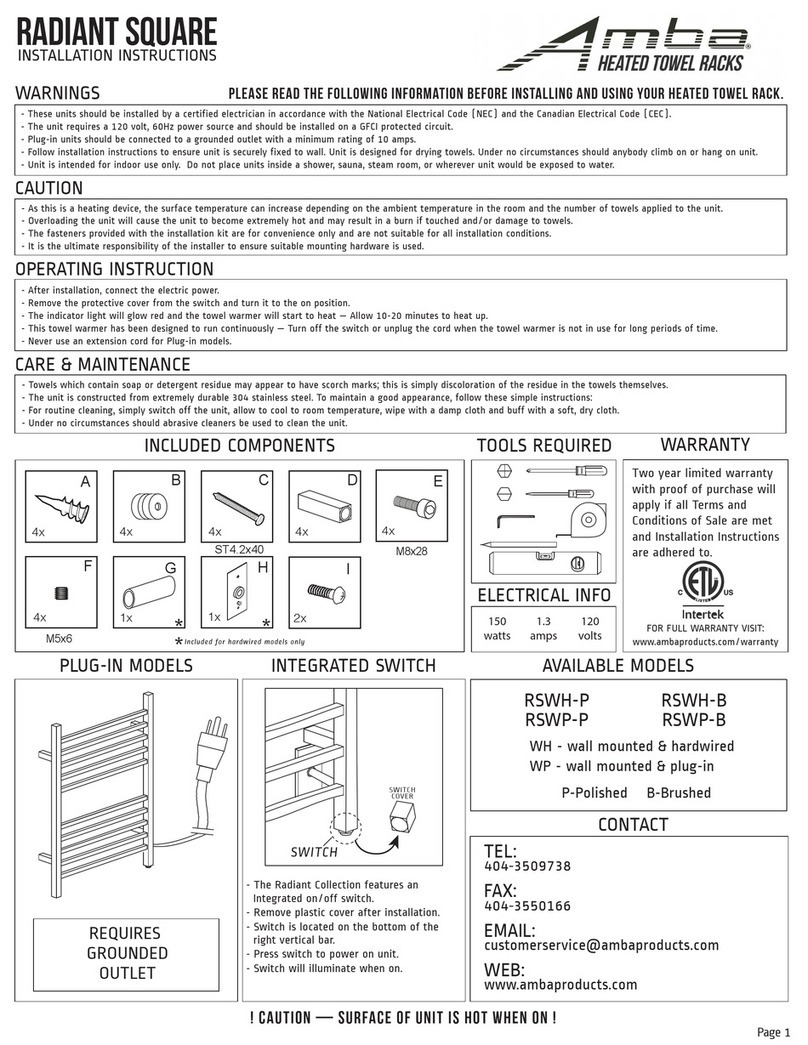

Figure 4.

Manifold with gas valve

8. Thread the new valve onto the manifold as

shown in Figure 4. Make sure it is tight.

9. Place gas rated thread sealer on the threads

of the valve.

10. Reconnect the burner tube.

11. Perform pressure check for leaks.

12. Install the bottom cover.

13. Connect the unit to the gas supply.

14. Turn the gas on and light the pilot.

15. Replace the galvanized burner liner.

Gas Operated Foodwarmers

8

Safety Valve Replacement

Figure 5.

Safety Valve

General

Safety valves are mounted between the gas control

valve and the burner (see Figure 5).

1. Shut off the gas supply.

2. Remove the galvanized burner liner.

3. Remove the screws the hold the bottom cover

in place.

4. Disconnect gas line and pilot tube on the inlet

side of safety valve.

5. Disconnect pilot tube and gas line on the outlet

side of the safety valve.

6. Disconnect the thermocouple from the safety

valve.

CAUTION: The thermocouple line is fragile.

Do not kink it.

7. Remove the safety valve from the unit.

8. Install the new safety valve, mounting screws

(if used) and thermocouple.

Note: Do not kink the thermocouple.

9. Apply gas approved thread sealer to all gas

and pilot tube ttings.

10. Check for leaks.

11. Install the bottom cover.

12. Connect the unit to its gas supply

13. Light the pilot light.

14. Replace the galvanized burner liner.

15. Verify that the burner lights properly.

Thermocouple Replacement

Figure 6.

Thermocouple

General

The thermocouple is connected to the safety

valve at one end. The probe end is near the pilot

burner.

1. Shut off the gas supply.

2. Remove the galvanized burner liner from the

pan.

3. Remove the screws the hold the bottom cover

in place.

4. Unscrew the thermocouple from the safety

valve.

5. Remove the probe end from the burner

area.

6. Replace the thermocouple.

CAUTION: The thermocouple line is fragile.

Do not kink it.

7. Perform leak test at safety valve tting.

8. Install the bottom cover.

9. Turn on the gas supply.

9

Gas Operated Foodwarmers

10. Light the pilot.

11. Replace the galvanized burner liner.

12. Verify the burner lights properly.

Pilot Replacement

Direct Burn Pilot

Figure 7.

Direct Burn Pilot

The pilot, Figure 7, for a direct burn unit is

connected directly to the gas supply manifold.

1. Shut off the gas supply.

2. Remove the galvanized burner liner from the

pan.

3. Remove the screws the hold the bottom cover

in place.

4. Remove the pilot tube from the manifold.

5. Slide the pilot tube away from the burner and

out of the unit.

6. Place gas approved thread sealer on the new

pilot tube tting.

7. Replace the pilot tube.

8. Perform leak test.

9. Install the bottom cover.

10. Turn the gas supply on.

11. Replace the galvanized burner liner.

12. Light the pilot.

13. Verify that the burner will light correctly.

Safety Valve Pilot

Figure 8.

Safety Valve Pilot

On units with a safety valve the pilot, Figure 8, is

connected to the safety valve.

1. Shut off the gas supply.

2. Remove the galvanized burner liner from the

pan.

3. Disconnect the pilot tube from the safety

valve.

4. Remove the pilot assembly from the unit.

5. Place gas approved thread sealer on new pilot

tube tting.

6. Replace pilot assembly.

7. Perform leak test.

8. Install the bottom cover.

9. Turn gas supply on.

10. Light pilot.

11. Replace the galvanized burner liner.

12. Verify that the burner lights properly.

Gas Operated Foodwarmers

10

Burner Replacement

Tube Burner

Figure 10.

Tube Burner

1. Turn off the gas supply.

2. Remove the galvanized burner liner, Figure

10.

3. Remove the burner from the gas supply

tube.

4. Replace the burner.

5. Turn on the gas supply.

6. Light the pilot.

7. Verify that the burner lights properly.

8. Replace the galvanized burner liner.

This manual suits for next models

7

Table of contents

Other Duke Food Warmer manuals