Page 7 of 8

5.0 Setting Day Time (Occupied) and Night Time Schedules cont.

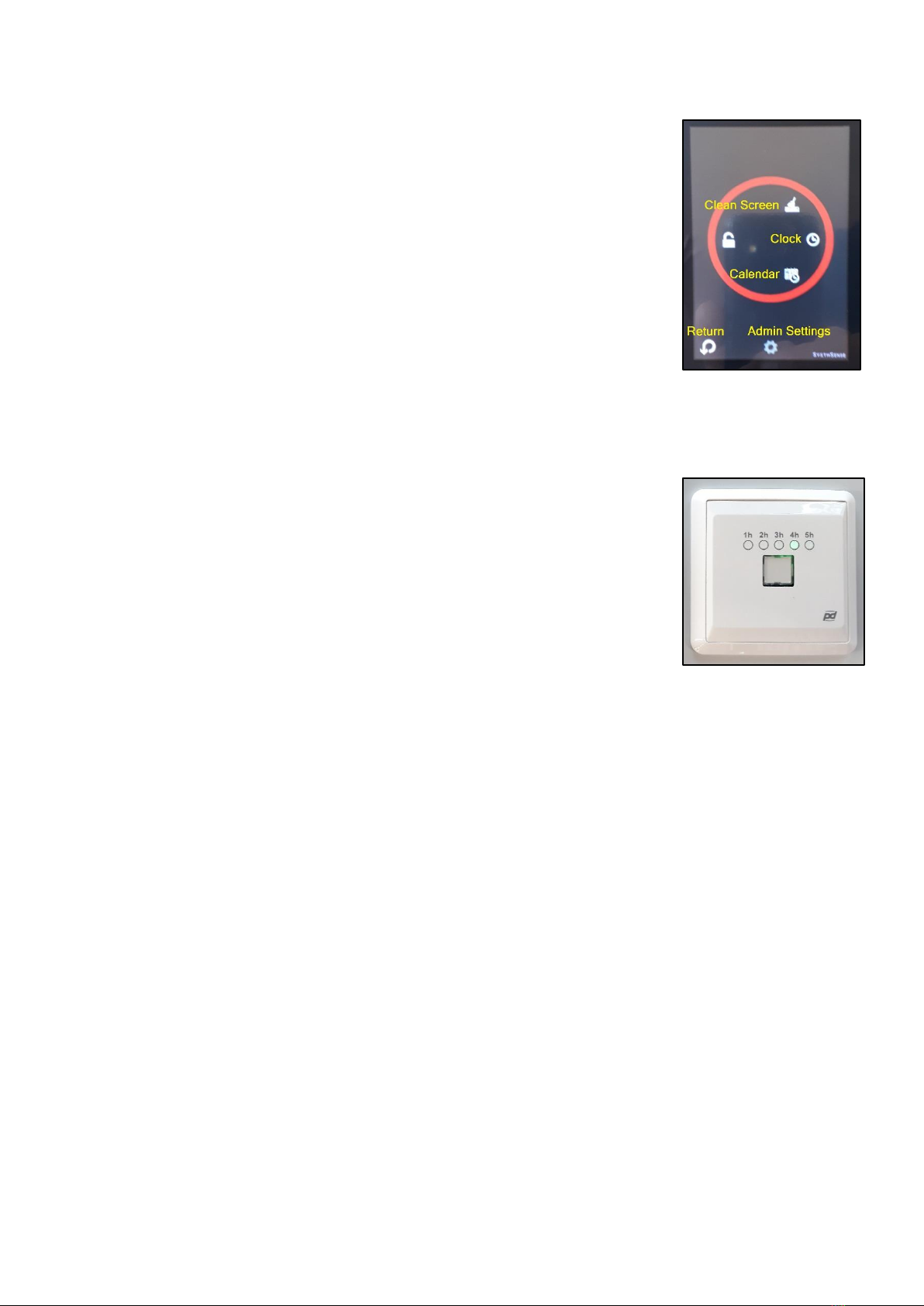

5.12 To change the system date and time, select the clock icon.

5.13 Check and revise the system date and time.

5.14 Select the Return button to return to the Main Screen.

5.15 To clean the touchscreen, select Clean Screen. The touchscreen will be

disabled for 30 seconds to allow the screen to be cleaned.

5.16 Diagram 9 shows the Menu Screen and relevant icons.

Diagram 9: Menu Screen

6.0 User Controls

6.1 User controls allow the day time (occupied) and night time settings to be

overridden, using the controls described below.

6.2

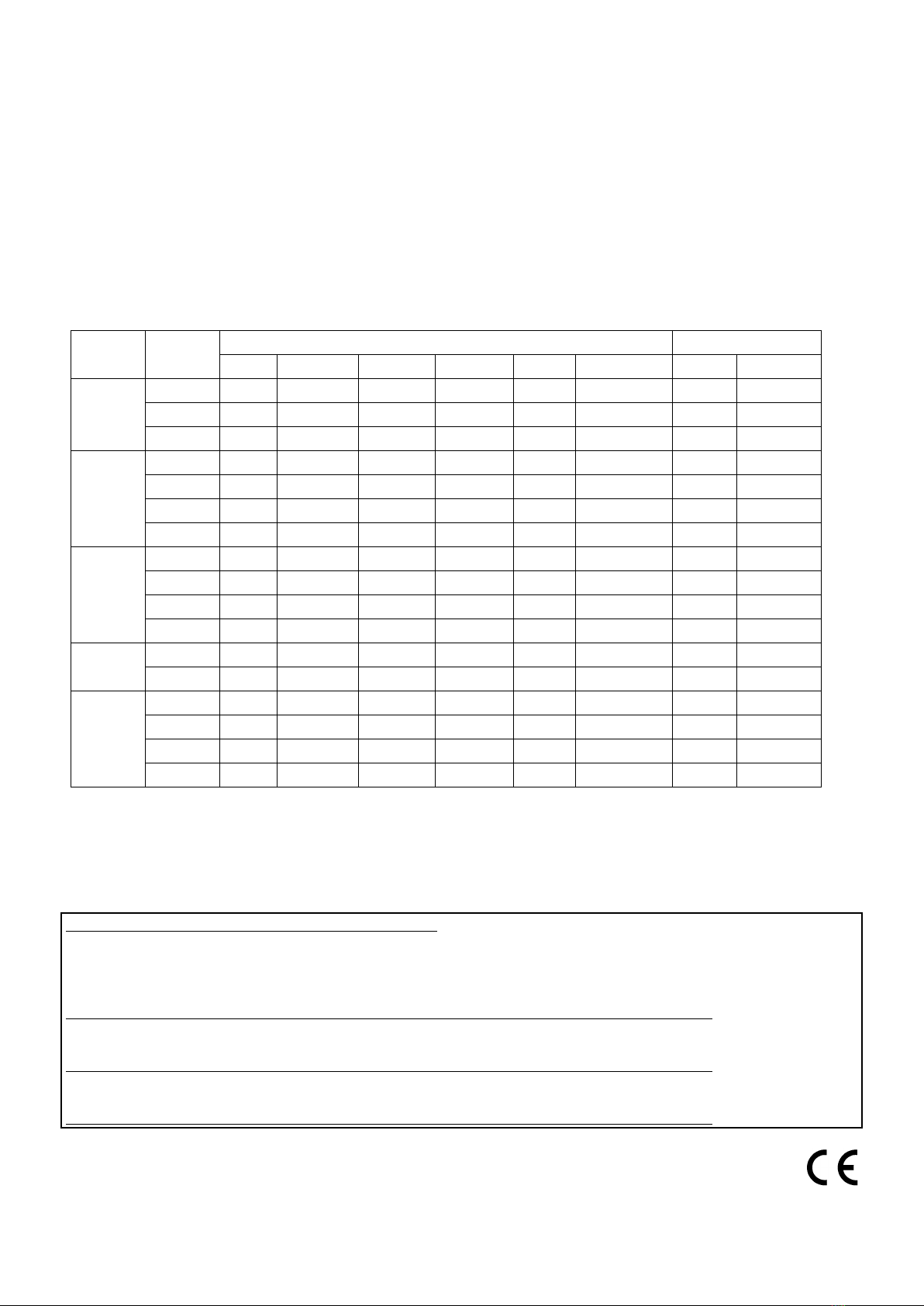

Timeclock Override Button

This button enables the daytime schedule to be extended up to five hours.

Press the button to cycle through the override periods (1h, 2h, 3h, 4h, 5h).

A green LED will indicate the selected override period; to return to

normal timeclock schedule, press the button to cycle through the periods

until no LED is lit.

6.3

Pre-Purge Switch

.

When enabled, all Smart-Vector units are run at full speed for 30 minutes

prior to start of daytime (occupied) schedule. On all Smart-Vector units, the

fresh air dampers fully open and fans run to purge treated spaces with fresh

air. Individual units are fitted with frost protection thermostats, which may

override fresh air dampers to circulate room air only

6.4

Day Time (Occupied) Cooling mode

When enabled, all Smart-Vector units will provide “free-cooling” by running

at full speed with fresh air dampers open, if room air temperature is more

than 1K above outside air temperature

and

above temperature setpoint.

Timeclock schedule for day time is user-programmable via the touch screen

and room temperature setpoint is user-adjustable via Smart-Vent room

controllers, with +/- 3K user adjustment

6.5

Night Time Cooling mode

When enabled, all Smart-Vector units will provide “free-cooling” by running at

full speed with fresh air dampers open, if room air temperature is more than

1K above outside air temperature. Timeclock schedule for night time is

user-programmable via the touch screen and room temperature setpoint is

user-adjustable via Smart-Vent room controllers, with +/- 3K user

adjustment.

Diagram 10: Timeclock

Override Button