9

Table of Contents

Chapter 1

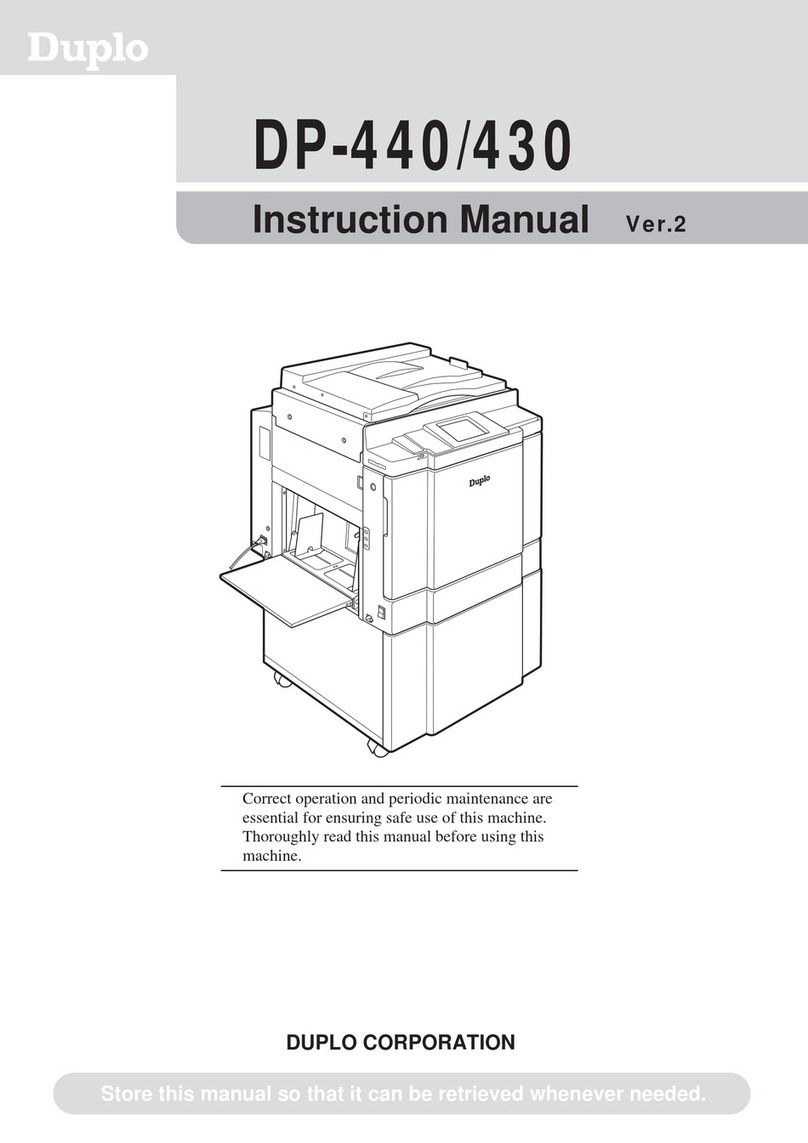

zSpecifications ......................................................................12

xDimensions ..........................................................................14

cSystem Setup.......................................................................16

vPart Names and Their Functions........................................17

Chapter 2

z

Scanner Section.........................................................26

x

Platemaking/Master Feed/Ejection Section.............36

c

Paper Feed Section ...................................................56

v

Drum Driving Section................................................68

b

Press Section.............................................................74

n

Paper Ejection Section..............................................79

m

Drum Section .............................................................85

Chapter 3

z

Exterior .......................................................................98

x

Scanner Section.......................................................103

c

Platemaking/Master Feed/Ejection Section...........109

v

Paper Feed Section..................................................116

b

Drum Driving Section..............................................120

n

Paper Ejection Section............................................122

m

Drum Section ...........................................................127

Chapter 4

z

Scanner Section.......................................................136

x

Platemaking/Master Feed/Ejection Section...........138

c

Paper Feed Section .................................................145

v

Drum Driving Section..............................................150

b

Press Section...........................................................152

n

Paper Ejection Section............................................154

m

Drum Section ...........................................................155

,

Electrical System.....................................................158

Chapter 6

z

Troubleshooting Guide ...........................................172

x

Error Display ............................................................189

Chapter 7

Chapter 8

z

Electrical Parts Layout and Their Functions.........282

x

Overall Wiring Layout..............................................293

z

HELP Mode List .......................................................194

x

Overview...................................................................198

cHELP Mode Functions and Operation Procedures

.......199

• Accessing HELP Modes.......................................199

• HELP Mode Descriptions .....................................200

Introduction.................................................................................1

Using the service manual ..........................................................2

Safety instructions ...............................................................3

1.Cautions regarding the installation location........................3

2.Cautions for installation work...............................................4

3.Cautions for maintenance, inspection and servicing .........5

• Locations of warning labels...................................................6

Troubleshooting

Chapter 5

z

Guaranteed Periodical Maintenance......................168

x

Cleaning and Oiling.................................................168

c

Periodical Maintenance...........................................169

Maintenance / Check

Standards / Adjustment

HELP Mode

Others

Mechanism

Description of the Operation

Introduction