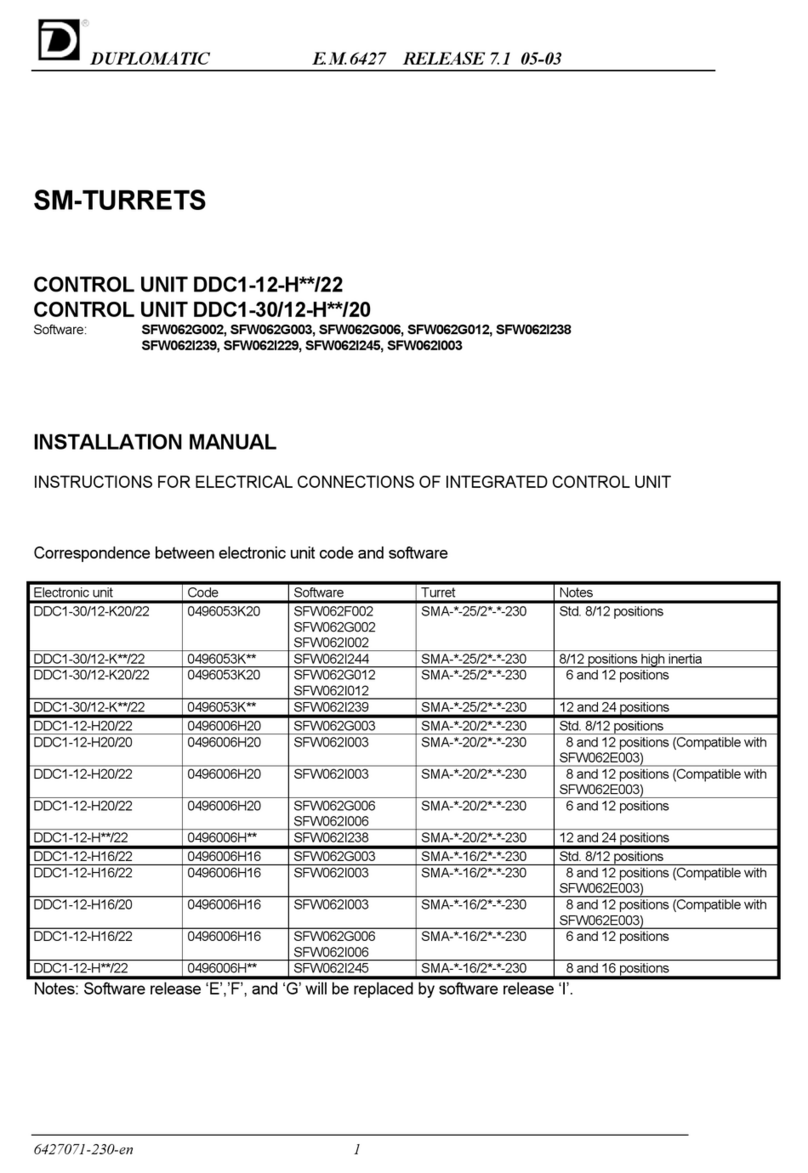

1 - IDENTIFICATION CODE

EPC

SERIES 10

3 - ADJUSTMENT

P1 ADJUSTMENT RANGE

3.1 - P1 - GAIN (Scale factor regulation)

Potentiometer “P1” enables regulation of the relation between the

set reference value and the current supplied to the solenoid, and

therefore regulation of the hydraulic parameter controlled by the

valve.

Adjustment range = 0 ÷100 % of maximum current

Single turn potentiometer - Rotate clockwise to increase current.

The EPC unit is a miniaturised electronic control unit for open loop

proportional valves, designed in plug version in compliance with

DIN 43650, for direct mounting on the valve solenoid.

The unit supplies a variable current in proportion to the input

reference signal and independently of temperature variations or

load impedence.

The PWM stage on the solenoid power supply makes it possible to

reduce valve hysteresis thus optimising control precision.

Potentiometers are also fitted for optimal calibration, and can be

accessed by slackening the relative screw and opening the cover

of the connector.

3.2 - P2 - RAMP (Ramp regulation)

Potentiometer “P2” within a range from 0,03 to 1,5 sec. regulates

the time required to reach the current according to a step change of

the reference signal up or down.

This makes it possible to control valve response and adapt it to the

requirements of the hydraulic system and the machine cycles.

Single turn potentiometer - Rotate clockwise to increase ramp time.

89 110/101 ED 2/4

Switching frequency:

0= 200 Hz 1= 100 Hz

4= 400 Hz

Maximum current:

1= 800 mA 2= 1200 mA

3= 1600 mA

Series No. (from 10 to 19 sizes and

mounting dimensions remain unchanged)

Power amplifier

DIN 43650 electrical connection

For single solenoid proportional valves

E P C - 1 / 10

P1 adjustment with

offset (P3) at max

P1 adjustment with

offset (P3) at zero

Reference

2 - FUNCTIONAL SPECIFICATIONS

2.1 - Electric power supply

The card requires a power supply of between 10 and 30 VDC

(ripple included).

NOTE: The value of the power supply voltage on the card must

not be lower than the rated working voltage of the solenoid to

be controlled.

The power supply voltage must be rectified and filtered, with

maximum admissible ripple within the above voltage range.

The power required by the card depends on the power supply

voltage and on the maximum value of the supplied current (it is

determined by the card version). In general a conservative value of

the required power can be considered as the product of V x I.

Example: a card with a maximum current = 800 mA and a power

supply voltage of 24 Vcc requires a power of about 20W. In case of

a card with a maximum current =1200 mA and a power supply

voltage of 24 Vcc the used power is equal to 30 W.

NB. Observe wire polarity and protect the power supply circuit

from overvoltages.

2.2 - Reference signal

The card accepts voltage reference signals of 0 ÷ +10V.

N.B: If the signal is transmitted by potentiometer, please verify

that this has a load of at least 5 KΩΩ(recommended 10 KΩΩ ))..

See par. 7 for electrical connections.

E0 = reference signal 0 ÷+10V (standard)

E2 = reference signal 0 ÷+5V