Instruction Manual

DRJ-10 Rail Jack - V1.2 www.durapac.com Page 2 of 10

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid injury or death

1.0 Product Information

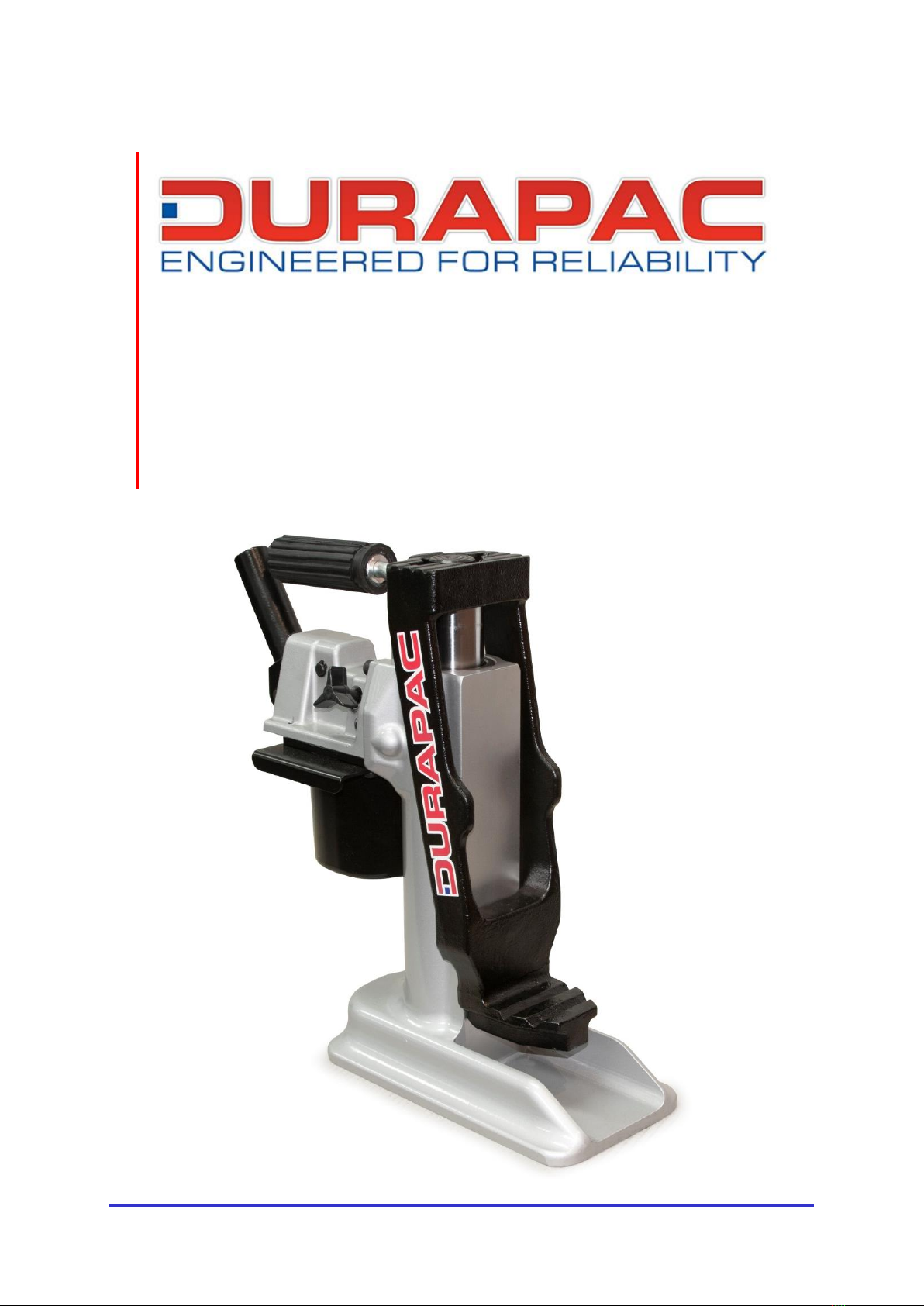

DURAPAC –Hydraulic Rail Jacks are engineered to meet Industrial Standards for Performance and

Safety. The DRJ-10 rail jack is ideally suited to aligning, gauging and lifting of rail or sleepers. Utilising

a forged aluminium upright base, this 10 ton1capacity jack has been designed to be robust, light

weight and reduce the risk of operator injury. It has a spring return mechanism that will allow a jack

with no load to be returned to the retracted position. The jack is fitted with an internal safety

pressure relief valve to protect against overloading. The bladder system inside the aluminium

protected reservoir allows the jack to be used in both the horizontal and vertical position making it

exceptionally versatile.

80cm removable extension handle

36kg maximum handle effort with extension handle

Release valve allows for controlled lowering and is recessed for protection against accidental

knocks

Internal oil reservoir bladder allows operation in horizontal or vertical position

Oil reservoir cover manufactured from aluminium (6061)

One piece of forged aluminium (7075T) base provides great support in soft ballast

Minimum base height of 50mm allows easy positioning under the base of the rail

10 ton1of lifting force

Indexed toe minimises swivel and allows for a safe, stable platform

Internal spring return allows an unloaded jack to return to the retracted position

Chrome plated steel piston rod resists corrosion and extends life

Fixed in-line padded carrying handle

Special skill, knowledge and training may be required for a specific task and the product may not be

suitable for all jobs. The user must ultimately make the decision regarding suitability of the product

for any given task and assume the responsibility of safety for all in the work area. Contact a Durapac

representative if you are unsure of your rail jack’s suitability for a particular application.

2.0 Receiving Instructions

It is recommended prior to use that an inspection be done by qualified personnel and that any

missing or damaged parts, decals, warning/safety labels or signs are replaced with Durapac

authorised replacement parts only. Any rail jack that appears to be damaged in any way, is worn,

leaking or operates abnormally should be removed from service immediately until such time as

repairs can be made. Any rail jack that has been or suspected to have been subject to a shock load

should be removed from service immediately until inspected by a Durapac authorised service centre.

Owners and operators of this equipment should be aware that the use and subsequent repair of this

equipment may require specialised training and knowledge.

1Nominal Jack Capacity in ton –see kN values shown in specification table (page 5) for actual capacity