Instruction Manual

HP-10 Bench Press - V1.4 www.durapac.com Page 4 of 13

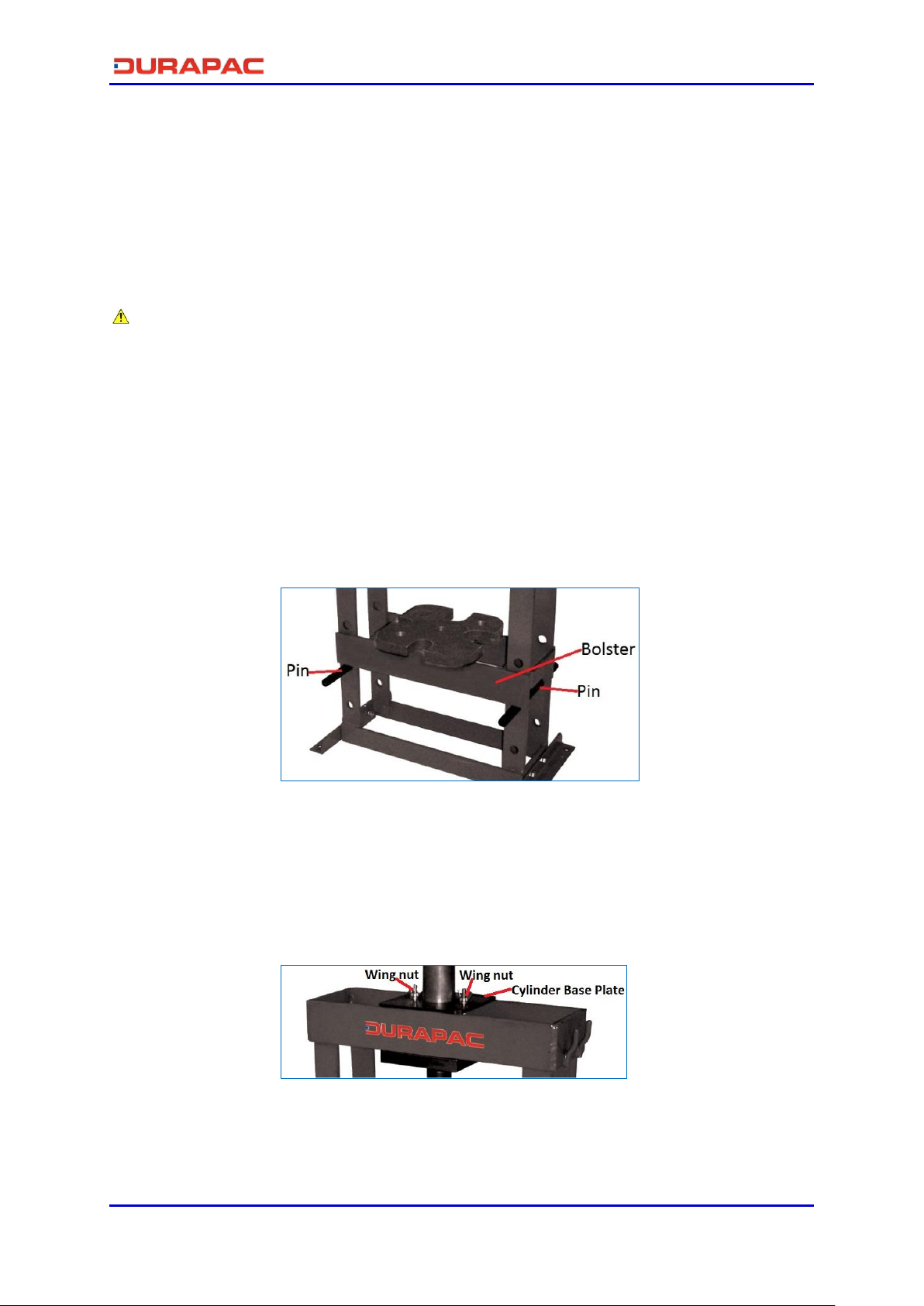

To prevent accidental slippage, do not place work pieces on the press bed, or apply

hydraulic force until all bolster pins are in place and all tension has been removed

from the bolster lift cables

Do NOT overload equipment. Overloading can cause equipment failure and possible

personal injury. The presses are designed for a maximum pressure of 700 bar

Do NOT stress adapters beyond their capacities. Any pushing or pulling adapters used

with this press must have a maximum tonnage rating equal to, or higher than, the

maximum tonnage rating of the press, or breakage can occur

It is impossible for Durapac to provide practical “all purpose” shielding because this is

a general all-purpose press that can be used in many different applications. The owner

of the press must supply shielding that is practical and necessary for each application.

Some safety can be provided by wrapping the piece in a protective blanket before

applying pressure

3.2 Hydraulic Hoses & Fluid Transmission Lines

Avoid short runs of straight line tubing. Straight line runs do not provide for

expansion and contraction due to pressure and/or temperature changes

Reduce stress in tube lines. Long tubing runs should be supported by brackets or

clips. Before operating the pump, connections should be tightened securely and

leak-free. Over tightening can cause premature thread failure or high pressure

fittings to burst

Should a hydraulic hose ever rupture, burst or need to be disconnected,

immediately shut off the pump and release all pressure. Never attempt to grasp a

leaking pressurised hose with your hands. The force of escaping hydraulic fluid can

inflict injury

Do NOT subject the hose to potential hazard such as fire, sharp objects, extreme

heat or cold or heavy impact

Do NOT allow the hose to kink, twist, curl, crush, cut or bend so tightly that the fluid

flow within the hose is blocked or reduced. Periodically inspect the hose for wear

Hose material and coupler seals must be compatible with the hydraulic fluid used.

Hoses also must not come in contact with corrosive materials such as battery acid,

creosote-impregnated objects and wet paint. Never paint a coupler or hose

FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL INJURY AS WELL AS PROPERTY DAMAGE.

4.0 Installation

Locate the press in an isolated area, or shield the press to minimize danger to others. Hydraulic

pressure can cause materials to break, possibly resulting in personal injury

Do NOT adjust safety valve pressure –safety valve pressure is set at 700 bar

4.1 Familiarise yourself with the details and illustrations in this owner’s manual. Know your

bench press, its limitations and how it operates before attempting to use. If in doubt,

contact a Durapac representative.