Index Page:

Part 2: Installation Instructions 745-34-2

1. Scope of delivery .............................................. 3

2. General notes ................................................ 3

3. Installing the sewing unit

3.1 Transport.................................................... 4

3.2 Removingthesecuritydevices....................................... 5

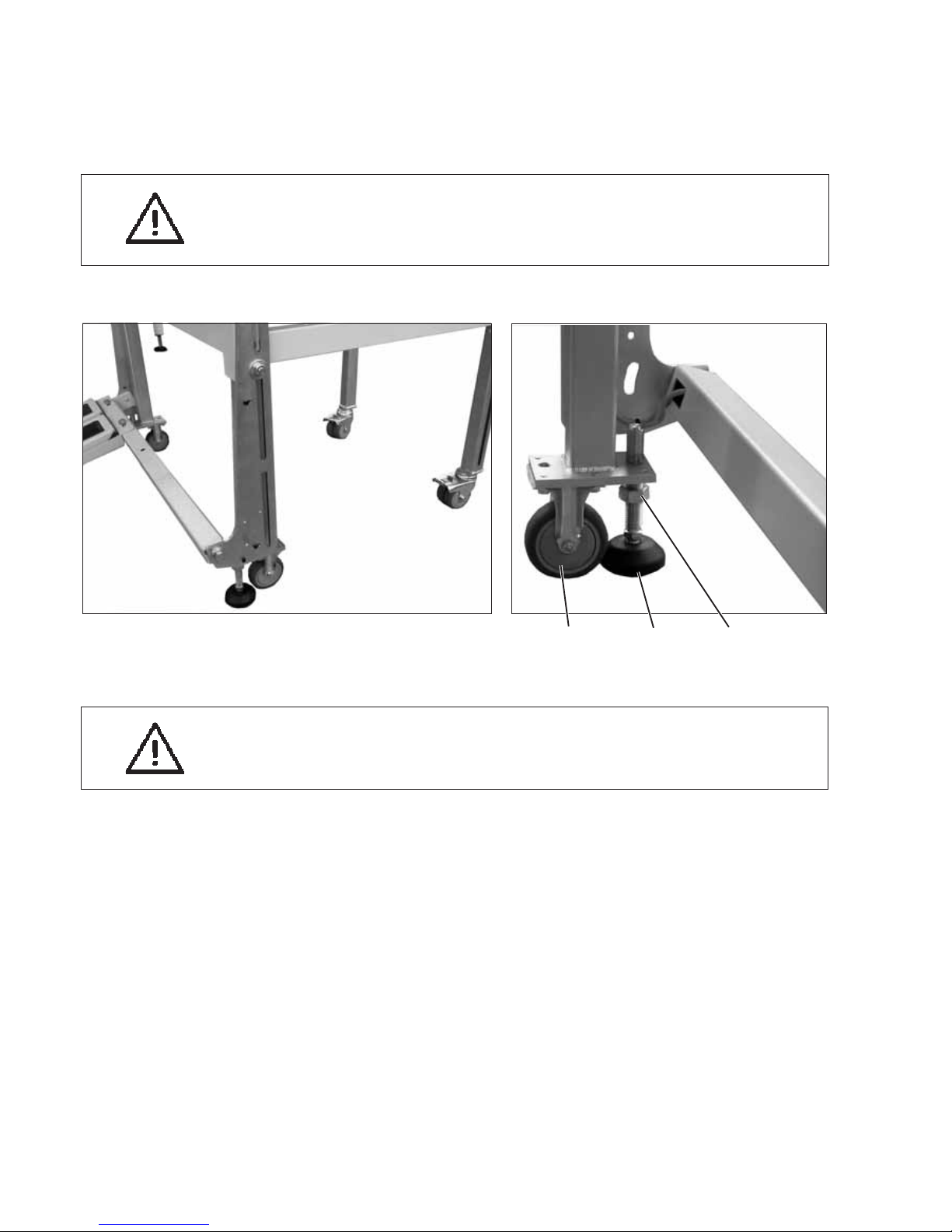

3.3 Settingtheworkingheight ......................................... 6

3.4 Adjusting the foot pedals .......................................... 7

4. Attaching the machine parts removed for shipping

4.1 Threadreelholder.............................................. 8

4.2 Cylinder for pick-up folder stroke ..................................... 9

4.3 Workpieceboxes............................................... 10

4.4 Fastening the holder for control panel, bobbin winder and right-hand tray............. 11

4.5 Table extension (optional equipment)................................... 12

4.5.1 Table extension for working method with bundle clamp carriage................... 12

4.5.2 Tableextensionforstackingtotheside ................................. 13

4.6 Throw-over stacker (optional equipment) ................................ 14

5. Electrical connection

5.1 Connecting the control panel DAC III ................................... 16

5.2 Connecting the external bobbin winder .................................. 16

5.3 Checking the nominal voltage and connecting to the mains ..................... 17

5.4 Checking the nominal voltage of the vacuum device (optional equipment) ............ 20

5.5 Directionofrotationofthesewingmotorandthevacuumblower ................. 20

6. Pneumatic connection ........................................... 21

7. Connection to the factory-own vacuum unit ............................. 22

8. Oil lubrication ................................................ 23

9. Commissioning ............................................... 24

10. Installing the sewing software

10.1 General..................................................... 24

10.2 Loading the program ............................................. 25

10.3 Dongle-Update via the Internet ...................................... 26

2