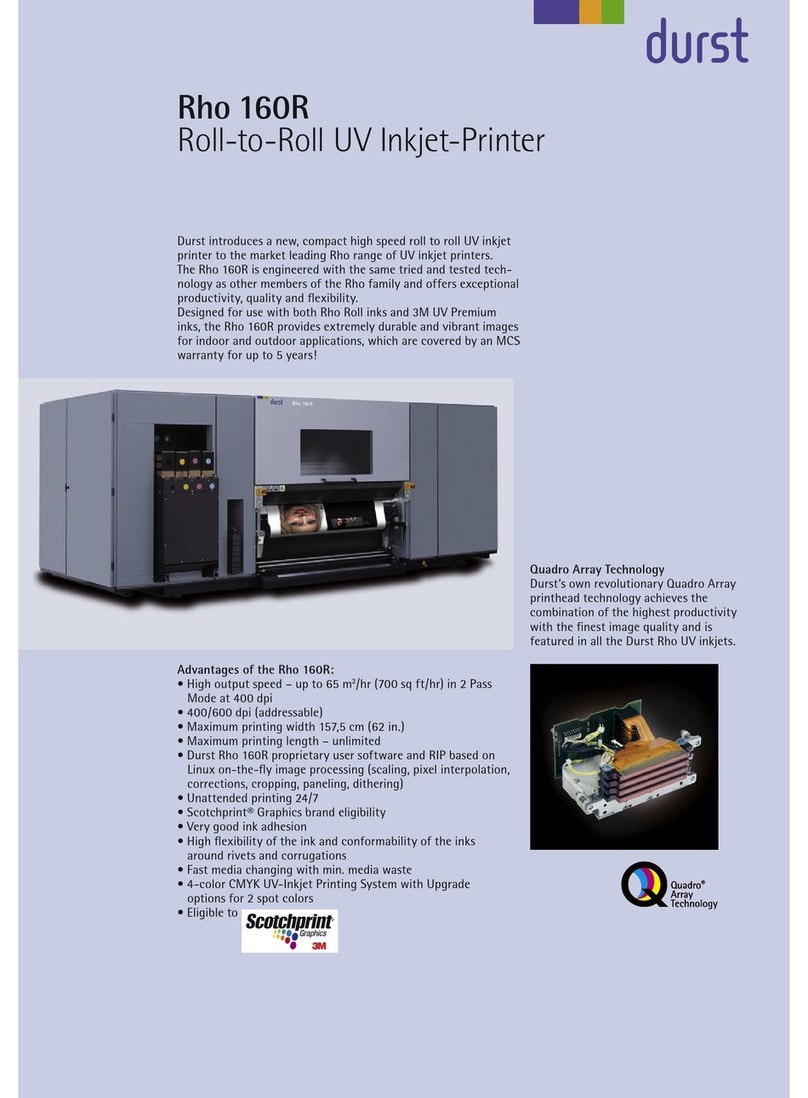

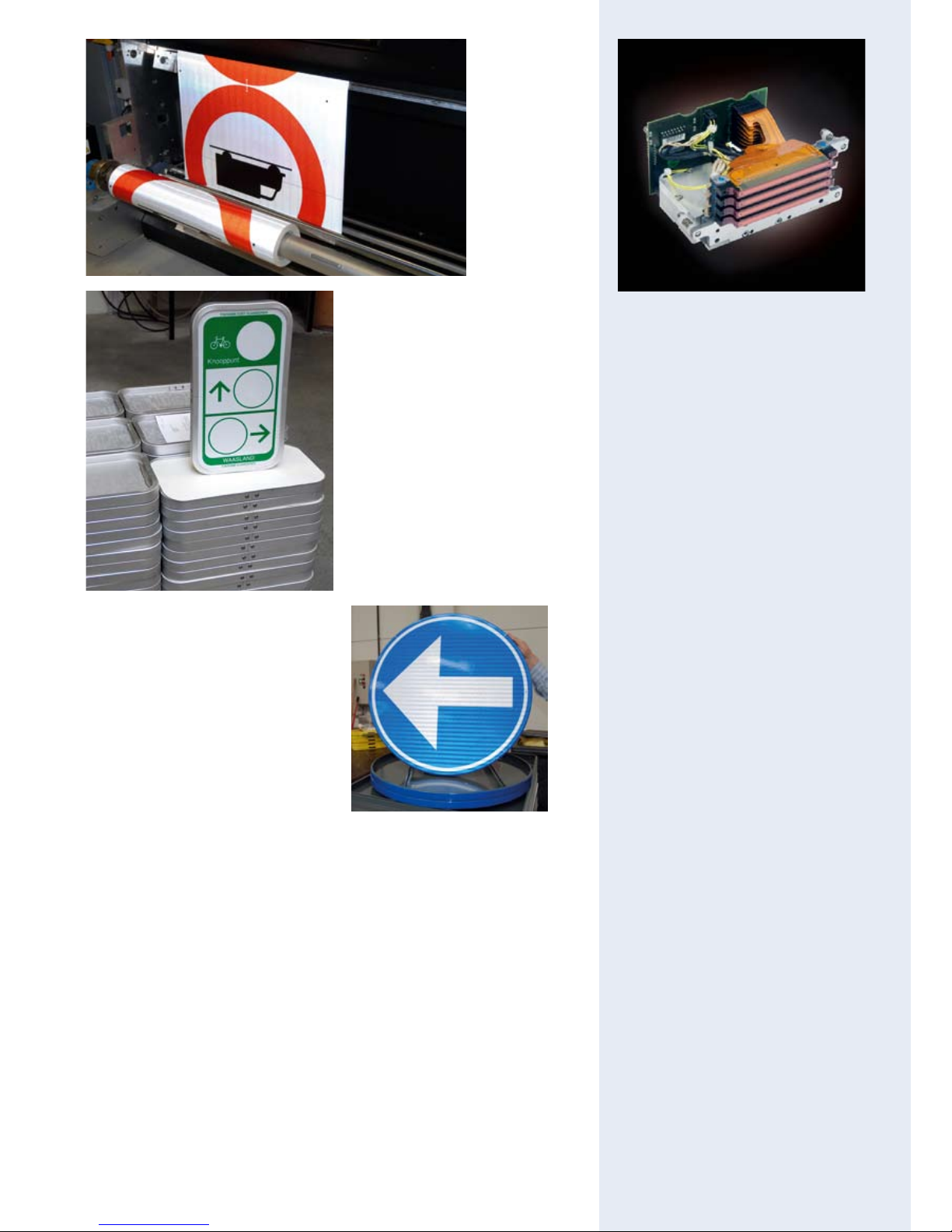

With advice from 3M, Janssens installed a

Rho 161 TS UV roll to roll printer last

September, which uses special media and

inks supplied by 3M. Mr Ivan De Coster,

Production and Quality Control Manager

of Janssens, said: “We have always used

3M consumables and wanted a machine

that was both suitable to our business

requirements and compatible with 3M inks

and materials. Durst and 3M worked closely

in the development of the machine and

although we are acting as a Beta site for the

new version of the Rho 161 TS, it has proven

to be very reliable. We are also very pleased

with its performance, the print quality is

excellent and its productivity is very high.”

Four weeks after the installation of the Rho

161 TS, Janssens also invested in a digital

cutting table. Prior to that the signs were

either stamped out or cut out by hand.

Mr De Coster commented, “We are printing

5 or 6 complete rolls of material a day

on the Rho and we needed to be able to

cut out the printed signs equally quickly.

From printing all our signs by the silk

screen process up to four years ago, we

now produce 75% digitally, it’s far more

convenient and turn around is much faster.

We started with short run or one-offs

being printed digitally, but now we print

anything up to 500 signs on the Rho, cost

effectively. Anything over that and it is

still more economical to use silk screen

particularly for the printing of single colour

signs.”

Janssens is responsible for the complete

process of traffic sign production, from

the delivery of plain sheets of aluminium

through to the finished sign. The raw sheets

of aluminium are cut and fabricated into the

correct shape of the sign, weather proofed

and powder coated ready for the finished

printed sign to be glued in place.

Belgium company uses

Durst Rho 161 TS for traffic

sign production

Janssens, based at Lokeren, near Ghent in

Belgium, has built its business on the

production of traffic signs since it was

founded in 1978. Initially production was

limited to a few standard signs printed by

the silk screen process. Today the company

is responsible for several hundred different

designs, many of which are in multiple

colours and it has also diversified into

different areas of road and traffic

management. Group Janssens, which

employs more than 160 people (32

manufacturing trafc signs), encompasses:

the installation of traffic signs, sign rental,

the production of traffic lights, illuminated

“speed warning” signs powered by solar

energy, road markings and a division that is

responsible for the renovation and upkeep

of bridges, buildings and car parks.

Janssens first decided to introduce digital

printing technology into the traffic sign

business four years ago when it invested in

a solvent printer. Digital print provided far

greater flexibility especially for low volume

work. However, there are environment issues

with solvent ink and the company believed

UV ink was the next step in developing a

better printing solution.