5

RMO30T Designated Use, Functionality

The inductance value of a transformer depends on the current injected in the windings. When the

transformer is saturated the inductance is minimized. A transformer is normally designed to reach

saturation when the current is 1,2 times the peak value of the no-load current. The no-load current is

normally in the range of 0,2% to 5% of the nominal winding current.

When measuring the DC resistance, the test current should be at least 1,2 times the no-load current of

the transformer. This is to ensure that the transformer core is saturated. Note also that the test current is

NOT to exceed approximately 10% to 15% of the nominal winding current.

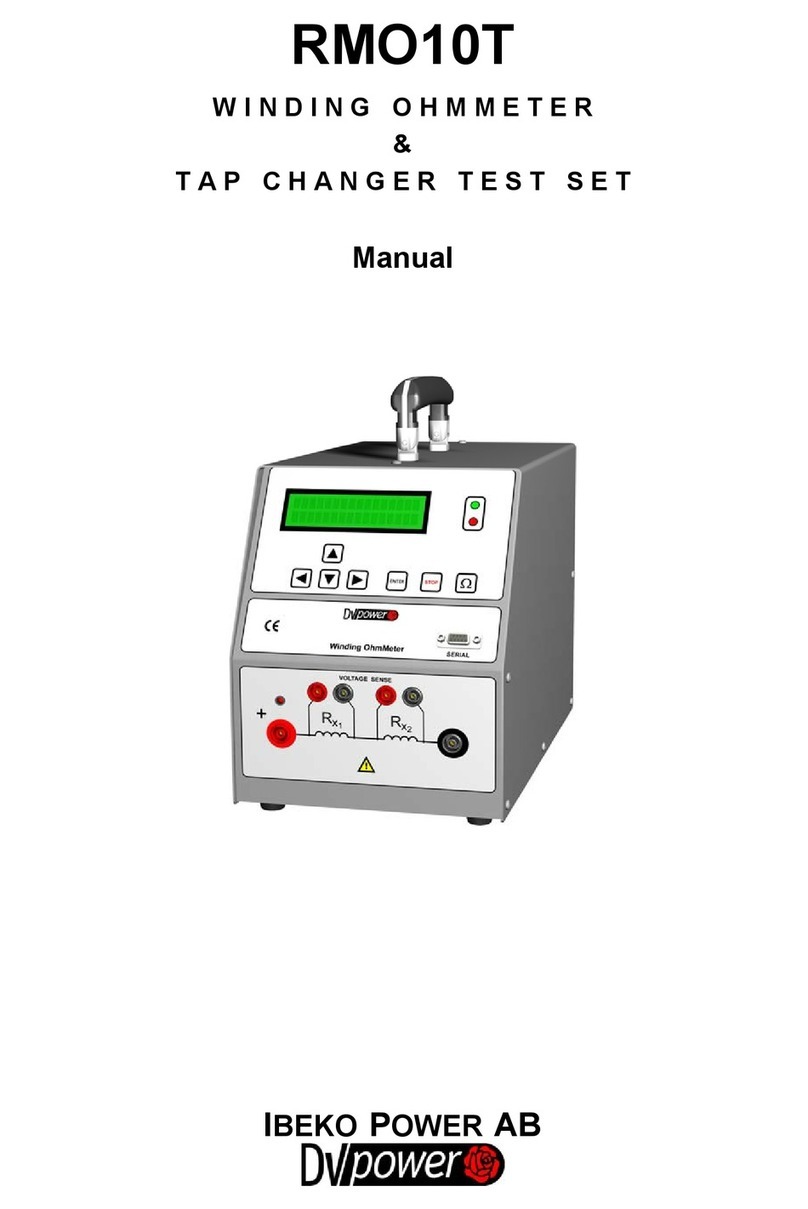

Note: The Voltage sense measuring channels are automatically selected connecting measuring cables

to those channels.

At the start of each test a check of cable continuity is done. In case of open circuit, an alarm is activated,

and the error message is shown on the display.

The test is started by pressing the START button. The RMO30T injects current with a voltage as high as

60V. This ensures the test to be as short as possible and that the desired test current is reached faster.

When the current is stabilized, RMO30T measures the resistance of the test object. The test result is

displayed as R=U/I. During the testing period, a new result is shown on the display approximately each

second.

Tests could be finished or interrupted two ways:

- Pushing the STOP button,

- Automatically, after the selected time has expired.

In both cases, upon completion of the test, a measured value of the resistance is recorded to pre-

selected internal memory location.

Each time the Ωbutton is pushed, results of the resistance and the test current value are stored into the

internal memory of RMO30T, and memory location changes to the next one.

Minimum measurement time is 60 seconds.

By pushing the STOP button test could be completed at any time. When the STOP button is pushed, the

last measured result will remain saved in the internal memory.

After the selected test time has expired, the last result remains saved at selected memory location.

Note: Using RMOWin-T5 the results could be stored to a PC, where reading interval of results is

adjustable. Results will be shown in a table in Excel format with an option to perform additional edit and

graphic presentation.

Using RMOWin-T5 after the test in order to transfer the results from selected internal memory location to

a PC, will allow transfer of the last test result only.

When the measurement is complete, RMO30T starts discharging the energy from the inductance. During

current discharging, the red discharge LED is lit and the buzzer is ON. Discharge is complete when the

discharge LED and the buzzer are OFF.

Both, injection of current and discharging energy from the inductance is fully automatically regulated. An

intrinsically safe discharge circuit, with indicator, dissipates the stored magnetic energy rapidly after the

test.

Cooling of RMO30T is supported by a built-in fan that is automatically activated when the device is

turned on.