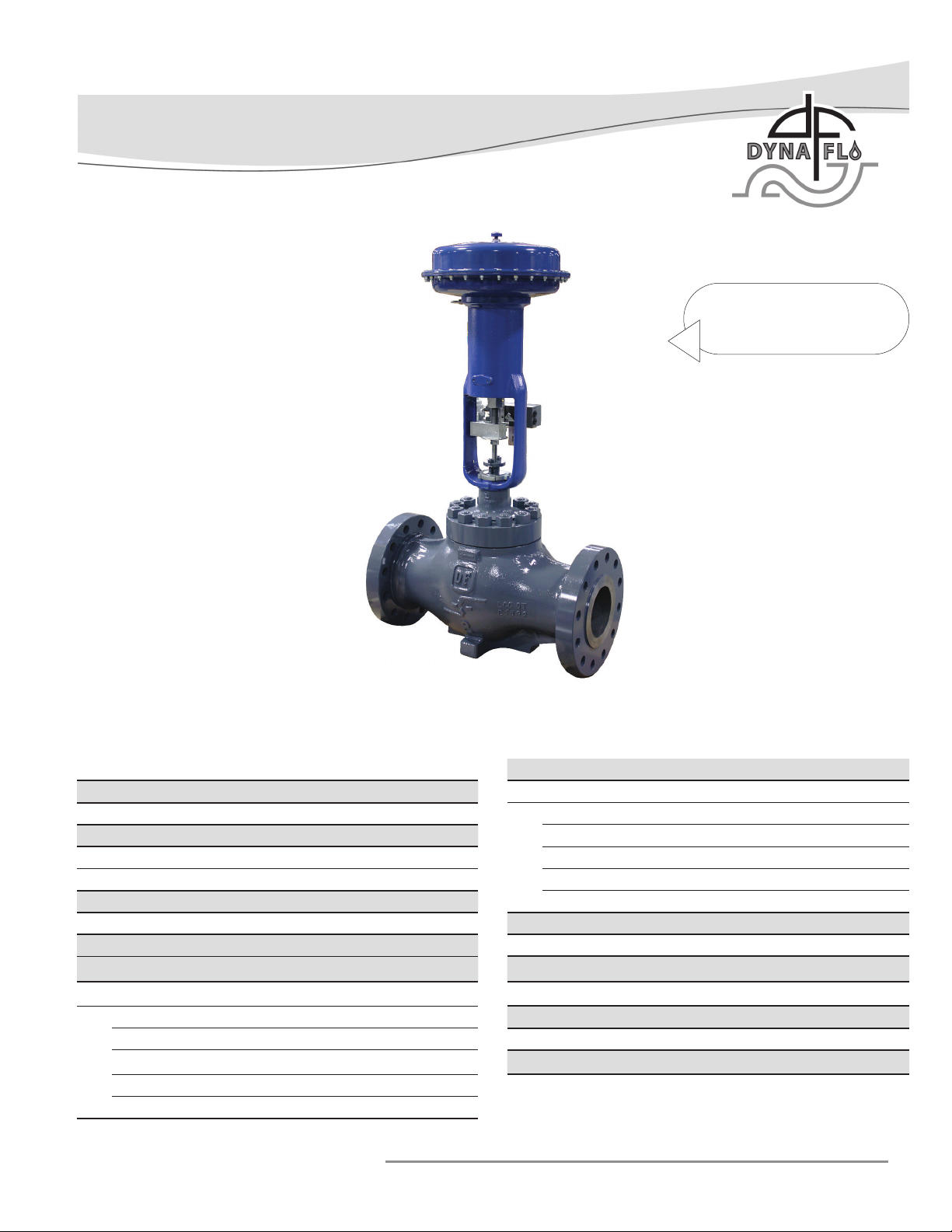

Model 350/351 Control Valves

Dyna-Flo Control Valve Services Ltd.

Phone: 780 •469 •4000 Toll Free: 1 •866 •396 •2356 Fax: 780 •469 •4035 Website: www.dynaflo.com

P-350M0620A 3

Operation, Parts, and Instruction Manual

SPECIFICATIONS

Configurations

The Model 350/351 control valve is a high capacity single

port, globe style valve, with a bolted type bonnet.

The Model 350H/351H control valve is a high capacity, high

pressure single port, globe style valve, with a bolted

type bonnet.

The standard valve plug action is push down to close.

PTFE Seat and Metal Seat Available.

Consult your Dyna-Flo sales office for other available

configurations.

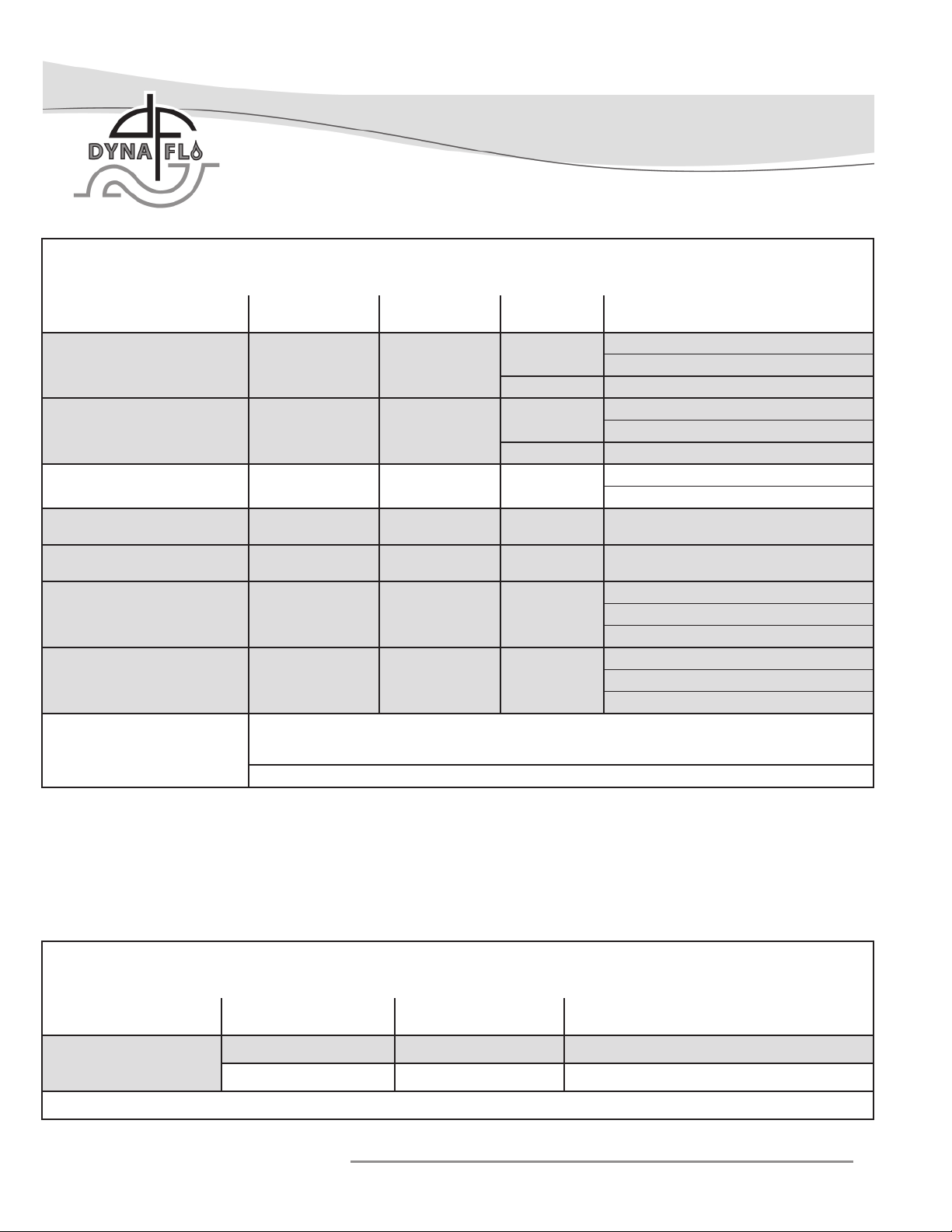

Sizes and Connection Styles

Models: 350, 350H, 351, and 351H

Size:

350, 351: 6x4”, 8x6”, 10x8”, 12x6”, and 12x8”

350H, 351H: 8x6”

Body: Globe

Rating:

350, 351: ASME 150 / 300 / 600

350H, 351H: ASME 900

Connections: RF / RTJ / BWE - Refer to Tables 1 and 2 for

available configurations.

Maximum Inlet Temperature and Pressures

Flanged valves consistent with ASME Class rating as per

ASME B16.34, unless limited as follows:

Temperature Limits: Tables 10, 12, 13, and 14 of Bulletin.

Standard Valve Trim: Figures 11, 12, and 13 of Bulletin.

Low-Noise Valve Trim: Figure 14 of the Sales Bulletin.

Anti-Cavitation Trim: Figure 15 of the Sales Bulletin.

Maximum Pressure Drops

Maximum pressure drop is the same as maximum inlet

pressure unless restricted by the following:

Standard Valve Trim: Figures 11, 12, and 13 of Bulletin.

Anti-Cavitation Trim: Figure 15 of Sales Bulletin.

Low-Noise Valve Trim: Figure 14 of the Sales Bulletin.

NOTE: 8x6 control valves are limited to ASME Class 600 pressure drops

unless used with Anti-Cavitation trim, 8x6 Anti-Cavitation valves are

capable of full Class 900 pressure drops.

Dimensions

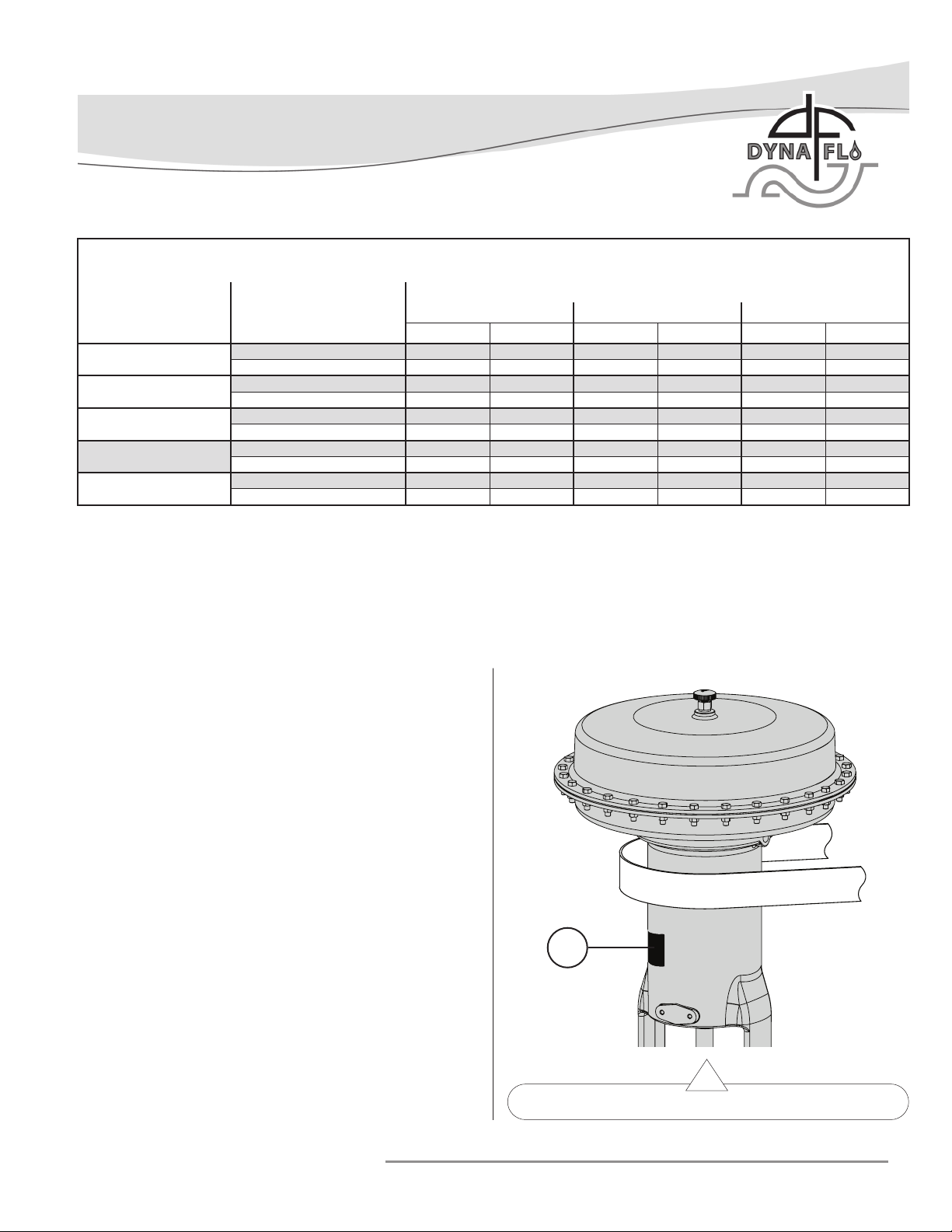

Valve and Actuator Outline Dimension Diagram

Refer to Figure 2 of the Sales Bulletin.

Valve and Actuator Assembly Dimensions

Refer to Tables 7 to 9 of the Sales Bulletin.

Characteristic and Flow Direction

•Equal Percentage (Standard) - Flow Down

•Quick Opening - Flow Down

•Linear - Flow Down

•Low-Noise (Linear) - Flow Up

•Anti-Cavitation 1-Stage (Linear) - Flow Down

•Anti-Cavitation 2-Stage (Linear) - Flow Down

Approximate Valve Body Weights

Refer to Table 3.

Materials

Body and bonnet material options include:

LCC (A350-LF2 optional* bonnet material)

WCC (A350-LF2 optional* bonnet material)

WC9 (A182-F22 optional* bonnet material)

CF8M (A182-F316 optional* bonnet material)

*NOTE: Dyna-Flo reserves the right to substitute a cast

material with the forged bar equivalent in the event a casting

is not available.

Refer to Figure 10 of Sales Bulletin for valve construction

material temperature limitations.

Refer to Tables 11 & 12 of the Sales Bulletin for trim

selections.

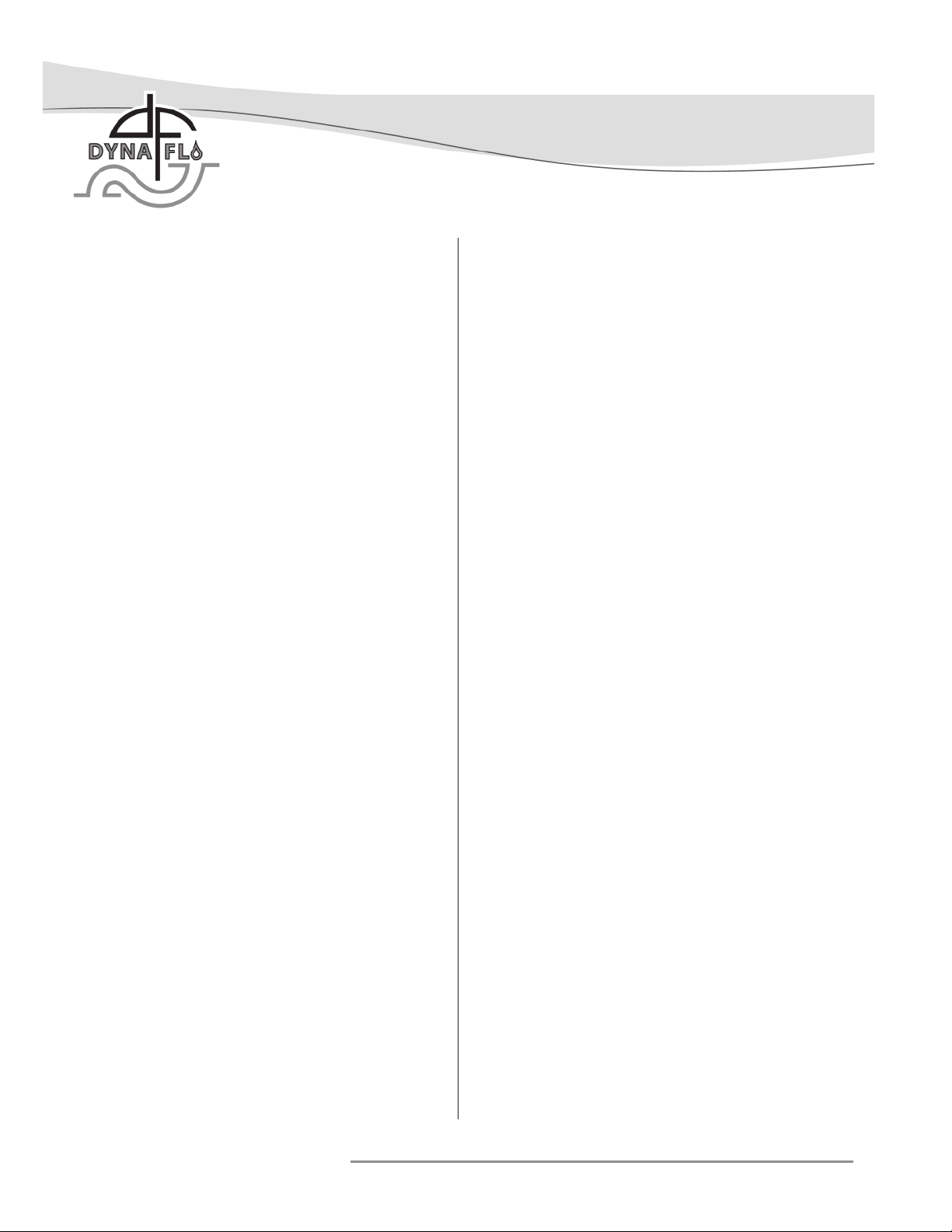

Cross-Section of the Model 350 & 351 Control Valves

Refer to Figure 34.

Port Diameters and Maximum Valve Plug Travel

Refer to Tables 3 to 5 of the Sales Bulletin.

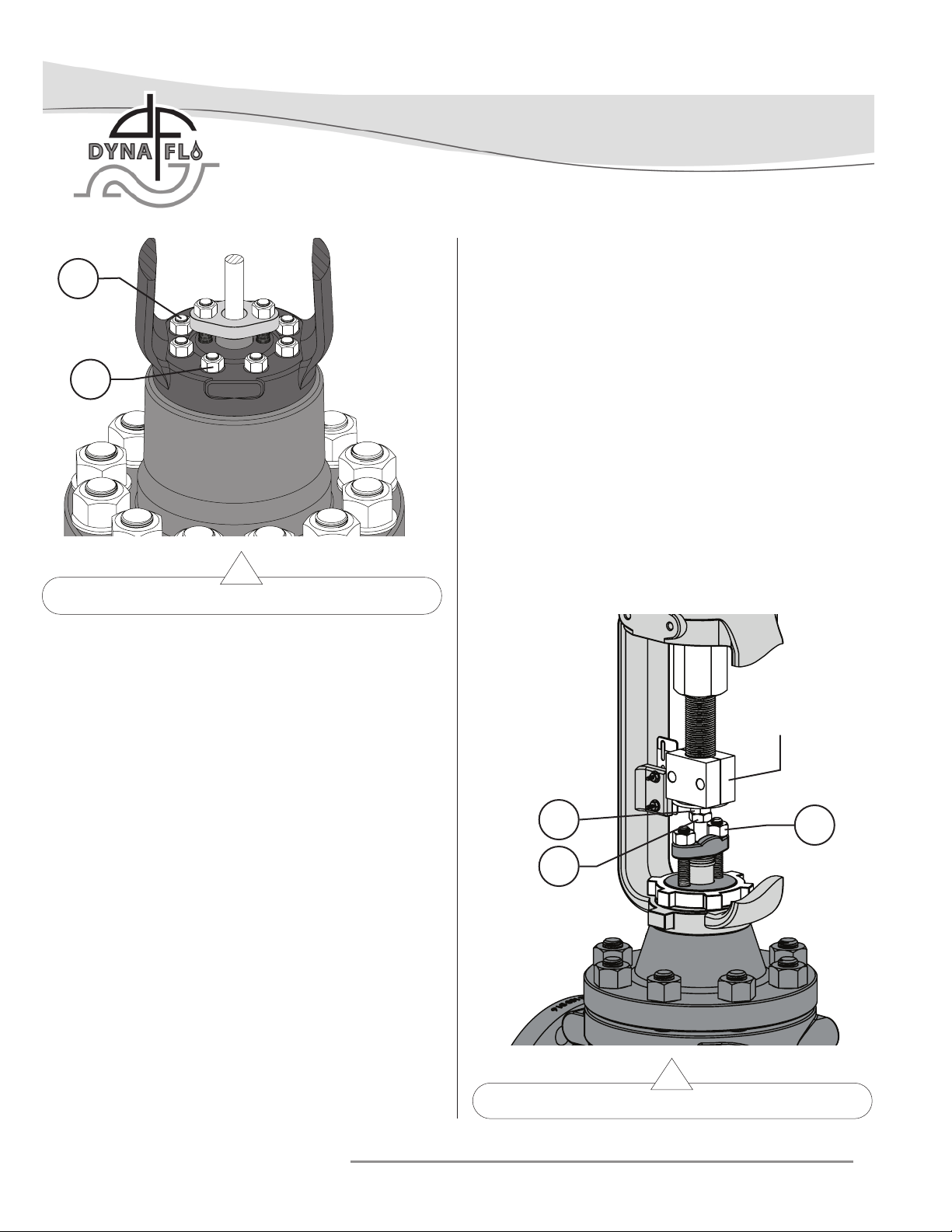

Packing Type

The Standard packing is PTFE V-ring. Live-loaded low

emission, graphite, KALREZ®, and other packing

arrangements are available. Refer to Figures 29, 31, 32, 33.

Maximum Valve Sizing Coefficients

For full list of coefficients refer to document P-CVSM.

Service Application

Refer to Tables 11, 12, & 14 of the Sales Bulletin.

For more information and other options contact your Dyna-Flo

sales office.