Model 360/361 Control Valves

Dyna-Flo Control Valve Services Ltd.

Phone: 780 •469 •4000 Toll Free: 1 •866 •396 •2356 Fax: 780 •469 •4035 Website: www.dynaflo.com

P-360M1019A 7

Operation, Parts, and Instruction Manual

PERIODIC INSPECTION

Special Equipment Required:

• Bypass or block valves.

Before You Begin:

• Read Safety Caution (Page 2).

• Use safe work practices and lock out procedures.

• Disconnect supply lines (air or gas), electric power, or control

signal to the actuator. Sudden movement of actuator can

cause damage or injury, make sure actuator will not operate.

• Vent any pneumatic actuator loading pressure and relieve

any actuator spring preload if present.

• Relieve process pressure and drain the process fluid from up

and down stream of valve.

• Be aware of potentially hazardous process material that may

be present in-line and in-valve. Isolate the valve from

process pressure. Use a bypass or block valve if necessary,

or completely shut off the process.

Inspection Steps:

1Check for visible signs of leakage around all seal and

gasket areas.

2Check the valve for damage, especially damage caused by

corrosive fumes or process drippings.

3Clean and repaint the areas as required.

4Ensure all accessories, mounting brackets, and fasteners

are secure.

5Clean any dirt and foreign material from the valve stem

(Key 5).

ACTUATOR REMOVAL

Note: Actuator removal does not require that the valve be

removed from the pipeline.

Tools Needed:

• Properly Rated Lifting Straps or Chains

• Lifting Device (Example: Crane)

• Hammer and Blunted Chisel

Before You Begin:

• Read Safety Caution (Page 2).

• Use safe work practices and lock out procedures.

• Disconnect supply lines (air or gas), electric power, or control

signal to the actuator. Sudden movement of actuator can

cause damage or injury, make sure actuator will not operate.

• Vent any pneumatic actuator loading pressure and relieve

any actuator spring preload if present.

1Refer to the appropriate actuator instruction manual for

more information regarding the actuator being removed.

2If the valve has been removed from the pipeline, place

the valve assembly on a flat work surface that can support

the weight.

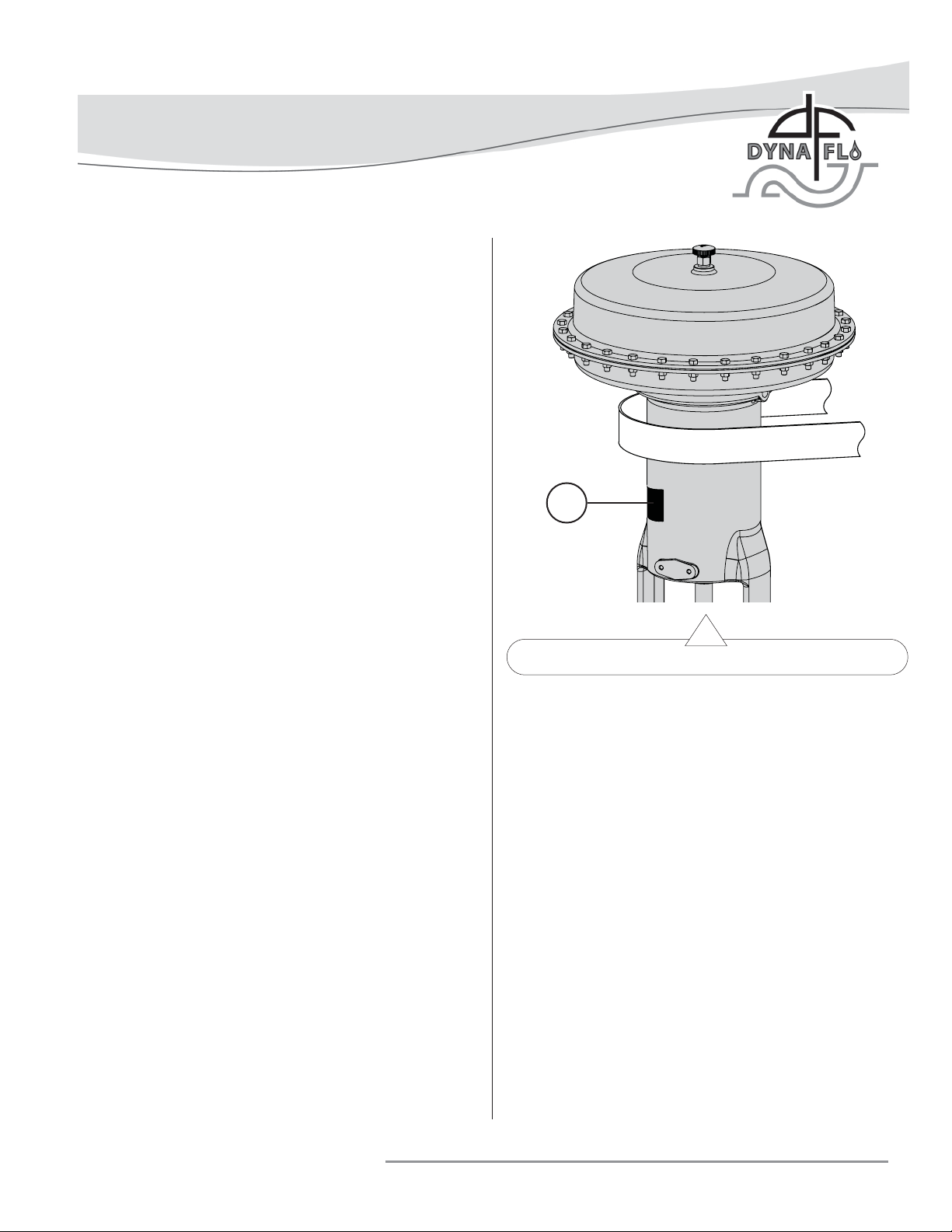

3Before the actuator is removed, support the actuator using

lifting hooks or straps rated to support the weight of the

actuator.

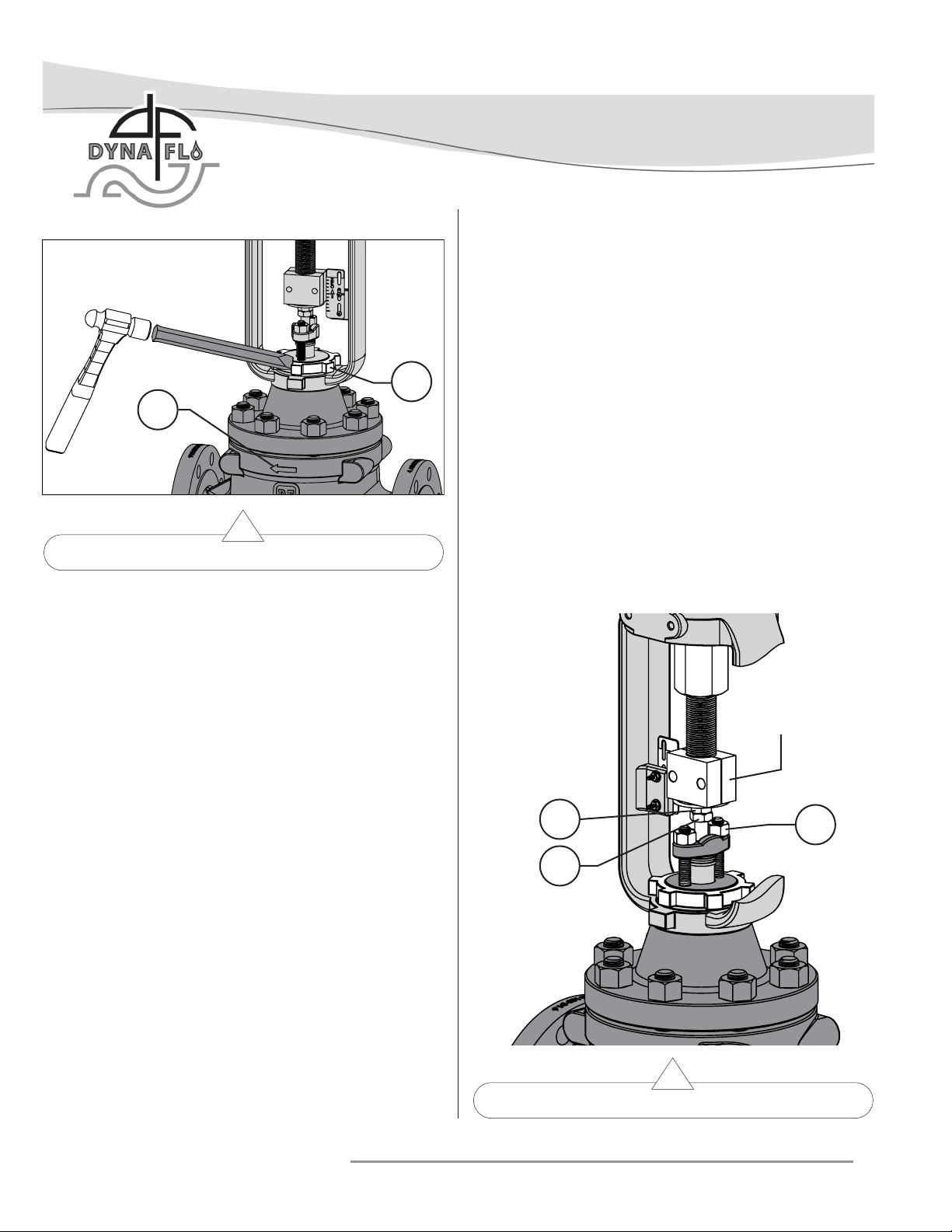

4If the actuator is a spring and diaphragm actuator,

determine if that actuator is fail open or fail closed. Fail

closed actuators will need to be energized to remove

downward force from the stem connector. Connect a supply

line to the inlet port of the actuator, be sure not to exceed

the maximum casing pressure. Refer to Figure 3 for

recommended needle valve and gauge setup.

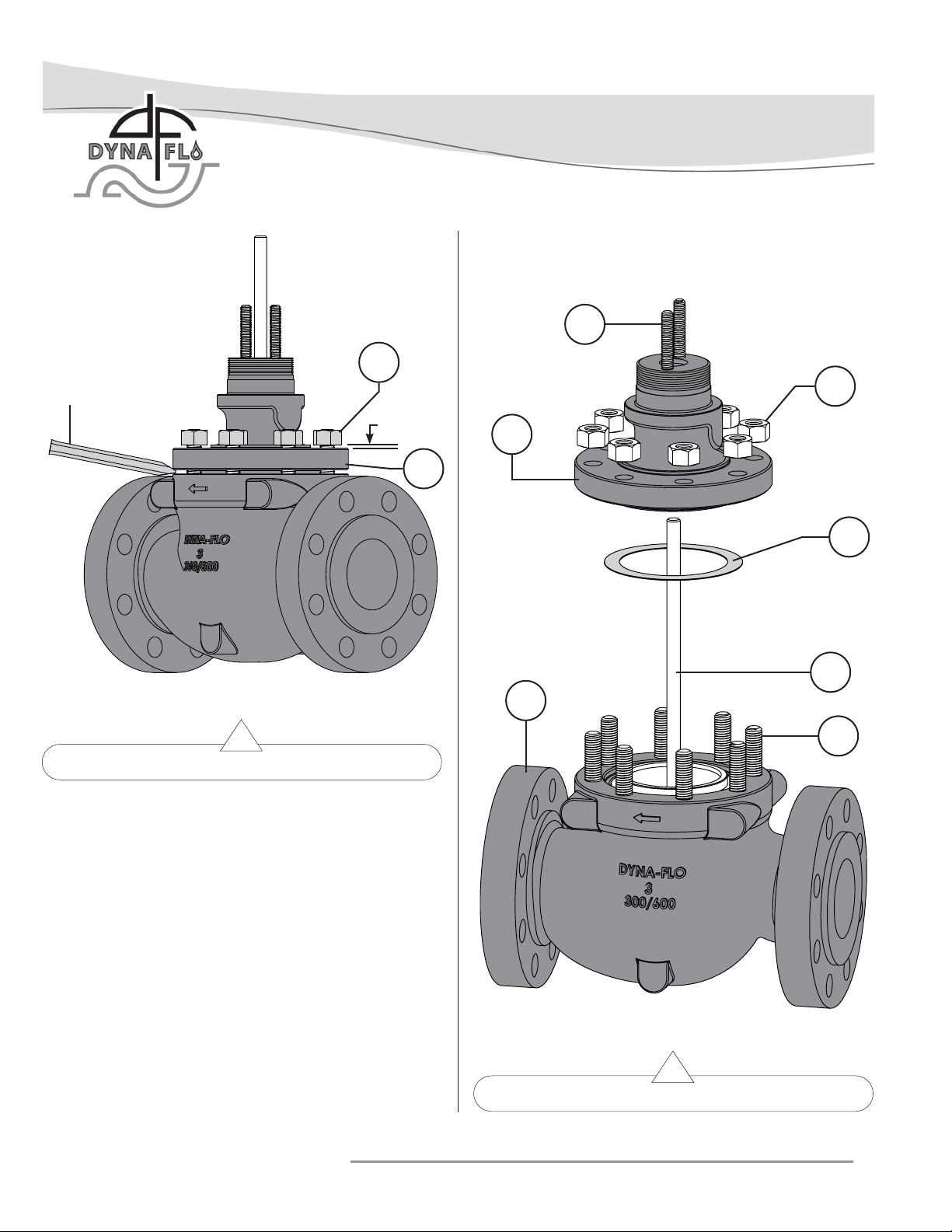

5Remove the stem connector (Refer to Figure 5).

6Use a blunted heavy chisel to loosen the yoke nut (Key

44). Unscrew the yoke nut and remove the actuator from

the valve. If the actuator was energize during removal,

de-energize the actuator (Refer to Figure 4).

7Remove the jam nut and hex nut (Keys 42 & 43) and travel

indicator from the valve stem (Key 5).

Figure 3 Needle Valve with Gauge setup