Dyna-Flo Control Valve Services Ltd.

Phone: 780 •469 •4000 Toll Free: 1 •866 •396 •2356 Fax: 780 •469 •4035 Website: www.dynaflo.com

Model 590 Control Valve

P-590M0817A 8

Operation, Parts, and Instruction Manual

PERIODIC INSPECTION

Special Equipment Required:

• Bypass or block valves.

Before You Begin:

• Read Safety Caution (Page 2).

• Use safe work practices and lock out procedures.

• Disconnect supply lines (air or gas), electric power, or control

signal to the actuator. Sudden movement of actuator can

cause damage or injury, make sure actuator will not operate.

• Vent any pneumatic actuator loading pressure and relieve

any actuator spring preload if present.

• Relieve process pressure and drain the process fluid from up

and down stream of valve.

• Be aware of potentially hazardous process material that may

be present in-line and in-valve. Isolate the valve from

process pressure. Use a bypass or block valve if necessary,

or completely shut off the process. For dual seal valves,

relieve internal pressure by removing the pipe plug (Key 37).

See Figure 38 on Page 32.

Inspection Steps:

1Check for visible signs of leakage around all seal and

gasket areas.

2Check the valve for damage, especially damage caused by

corrosive fumes or process drippings.

3Clean and repaint the areas as required.

4Ensure all accessories, mounting brackets, and fasteners

are secure.

5Clean any dirt and foreign material from the valve shaft

(Key 17).

MAINTENANCE

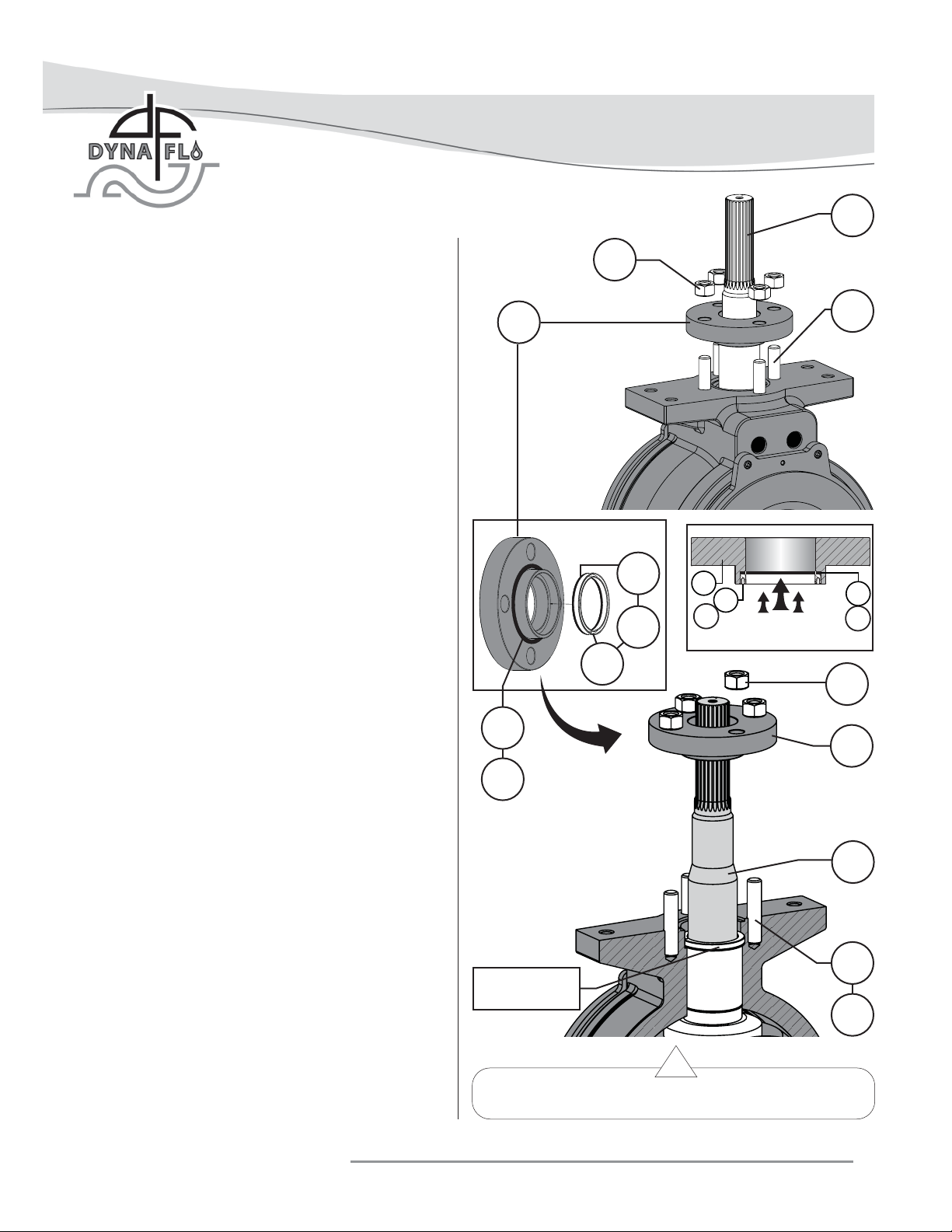

Note: Shaft seals or live loaded packing and ball seals (Key 30)

should all be inspected frequently for leaks, wear and

damage. Maintenance to the shaft seals or live loaded packing

can be made while the valve is still in-line, the actuator must

be removed for drive shaft (Key 17) seal/pacing maintenance

(See Page 12 for Actuator Removal instructions).

Note: Perform ball seal (Key 30) maintenance when the control

valve will not properly shut off. Ball seal maintenance can be

performed without removing the actuator from the valve. Ball

seal maintenance cannot be performed with the valve in-line.

When removing the valve from pipe line be sure it is in the

OPEN position, verify the valve is open using the indicator

scale (Key 24) before removing from line.

Note: When testing the seal integrity of the valve using the

pipe plug port (dual seal configuration), it is recommended that

the pipe plug (Key 37) be replaced by a hand valve. A hand

valve will allow valve pressure to be relieved safely during

seat leak rate testing. See Figure 38 for pipe plug location.

Before You Begin:

• Read Safety Caution (Page 2).

• Determine if valve has shaft seals or live loaded packing

(See Figures 31 & 37).

• Determine if valve is single seal or dual seal (See Figures 37

& 38).

• Follow Steps 2 – 5 of PERIODIC INSPECTION Before you

begin.

SHAFT SEAL MAINTENANCE

Note: It is recommended that the follower shaft seal and the

drive shaft seal be replaced at the same time. The actuator

must be removed for drive shaft seal maintenance. For live

loaded packing see Page 25.

Special Tools Required:

• Mechanics Pick Set

Lubricants Required:

• Anti-Seize Compound (Key A)

• Silicone-based O-Ring Compound (Key B)

• White Petroleum Grease (Key C)