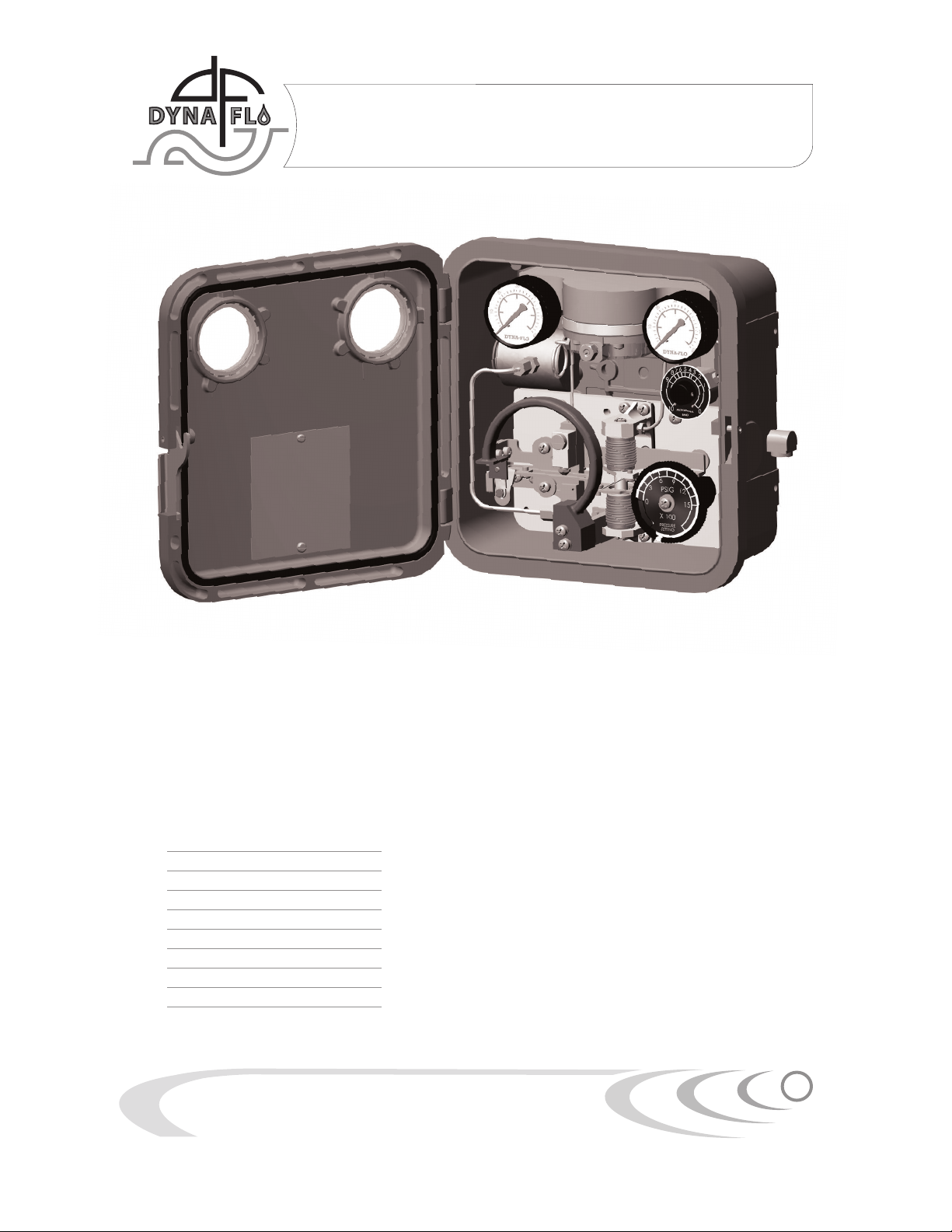

Model

4000 Pressure Controller

Operation, Parts and Instruction Manuals

Dyna-Flo Control Valve Services Ltd.

Edmonton, Alberta, CANADA

Website: www.dynaflo.com

Phone: 780 • 469 • 4000

Toll Free: 1 • 866 • 396 • 2356

Fax: 780 • 469 • 3149

Instruction Manual October 2005

8

Relay Manifold

Replacement

Refer to Figure 4.

A Always shut down the supply, control and p

process pressure line to the controller.

B Disconnect the relay tubing (Key 58) from the

relay manifold (Key 56).

C Remove the relay manifold (Key 56) from the

case by unscrewing the 2 retaining screws

(Key 39 - not shown) on the back of the case.

D Remove the gauges, proportional band, and

elbow fitting from the manifold. Install the

gauges, proportional band, and elbow fitting

into the new replacement manifold.

E Replace the relay manifold o-rings (Key 57).

Place the o-rings on the inlet and outlet fittings

on the relay manifold. With the manifold in

place, insert and fasten the 2 screws (Key 39-

not shown) from the backside of the case.

F Connect the tubing, and check all connections

for leaks.

G Perform calibration procedure.

Relay Reconditioning

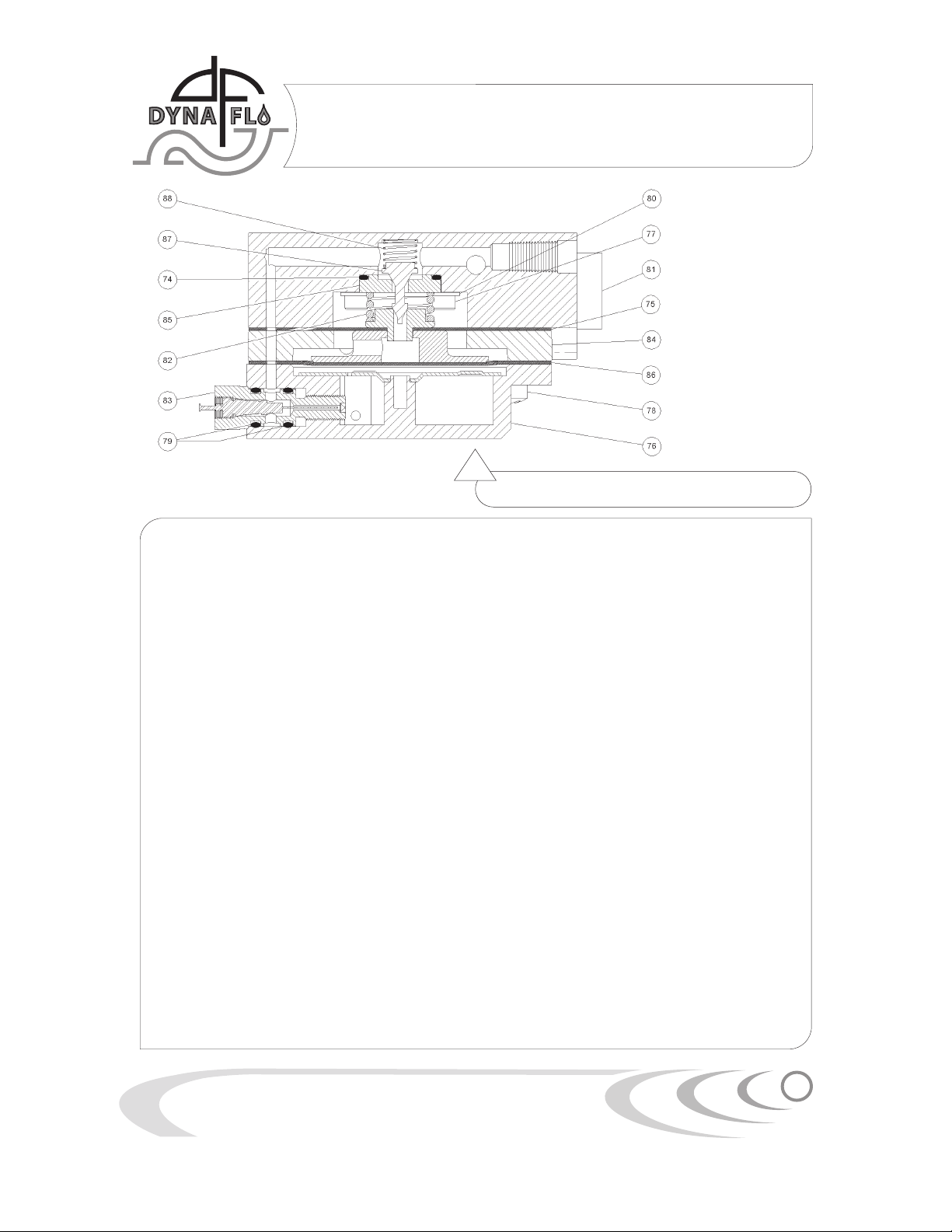

Refer to Figure 3.

Disassembly

A Complete steps A through D of relay manifold

replacement.

B Unscrew the orifice assembly (Key 83). Remove

the o-rings (Key 79) from the orifice assembly.

C Place the relay manifold on the work surface

with the casing screws facing up. Remove the

casing screws (Key 78), in a criss-cross

pattern.

D Remove and separate the lower casing (Key

76) bottom diaphragm (Key 86), spacer ring

(Key 84), diaphragm assembly (Key 75), relay

spring (Key 82), and valve plug spring (Key 88)

from the relay manifold (Key 81).

E Inspect the valve seats (under a good light) for

roughness due to corrosion. One seat is located

in the diaphragm assembly (Key 75), and the

other seat is located on the seat ring (Key 85),

which is found in the relay manifold (Key 81).

Replace the diaphragm assembly or seat ring

if seats are damaged or worn.

F To install a replacement seat ring (Key 85) in

the relay manifold, remove the 3 screws (Key

77) and washers (Key 80) retaining the seat

ring. Remove the seat ring (Key 85), and o-ring

(Key 74) from the seat pocket in the relay

manifold.

G Inspect diaphragms and gaskets, and replace

them if necessary.

H Replace the spring and valve plug if they show

signs of corrosion.

I The lower diaphragm is part of the diaphragm

assembly and must be replaced as an assembly.

J Clean all parts thoroughly before re-assembling.

Re-assembly

A With the opening in the relay manifold facing

up, place the valve plug spring in the bottom of

the manifold. Carefully place the valve plug on

top of the spring, such that the plug is pointing

up.

B Install the seat o-ring in the pocket of the relay

manifold. Carefully place the seat ring on top

of the o-ring, ensuring the plug is sticking

through the seat ring.

C With the seat ring in place, install the 3

screws and washers that retain the seat ring.