INSTRUCTIONS : PR-2500-UD Cod : DYN 05.01.08

Date: 15/04/2016 Revision: 08

2

INSTRUCTIONS FOR USE AND MAINTENANCE

_____________________________________________________

1GENERAL INSTRUCTIONS .................................................................................................................................... 3

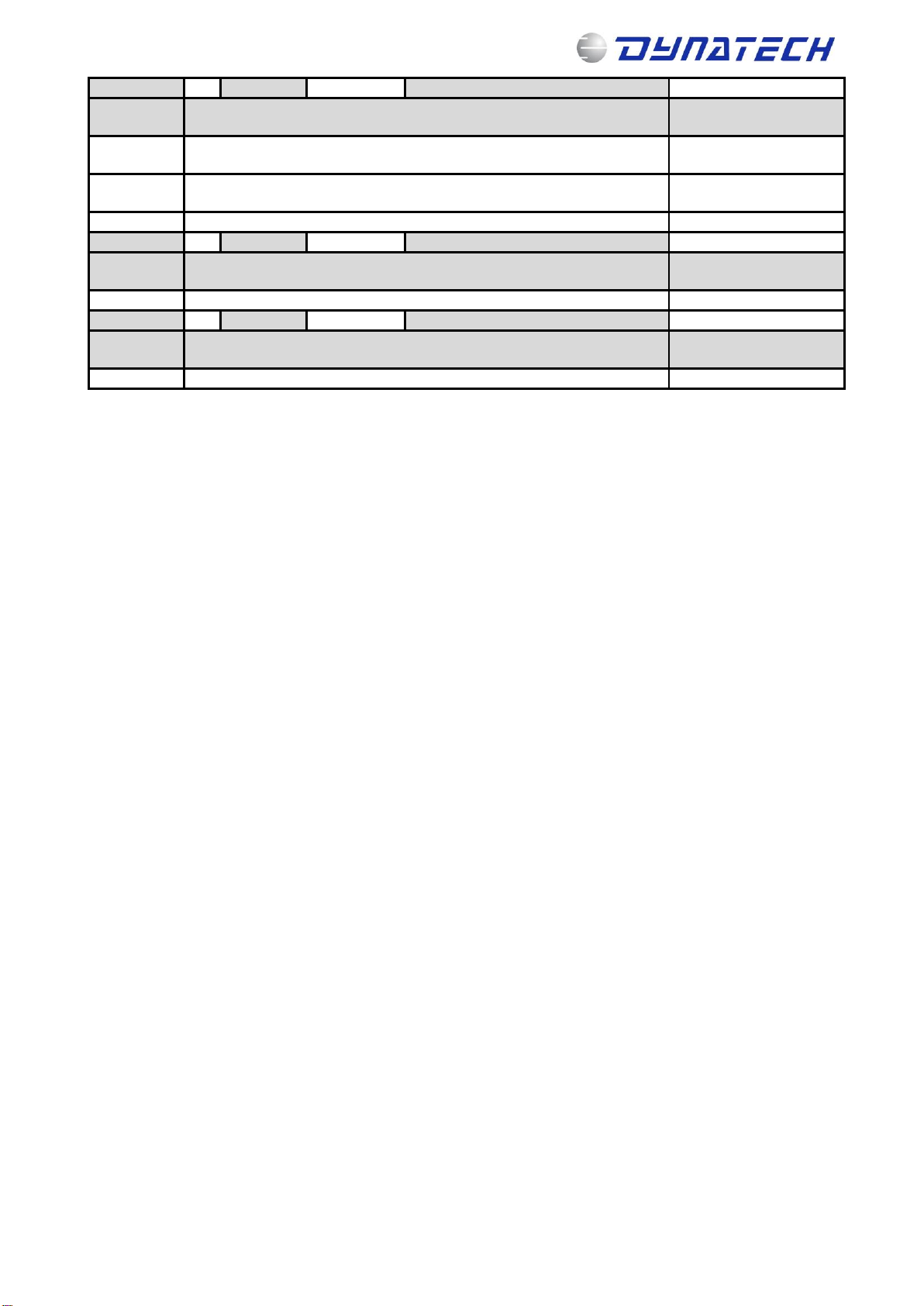

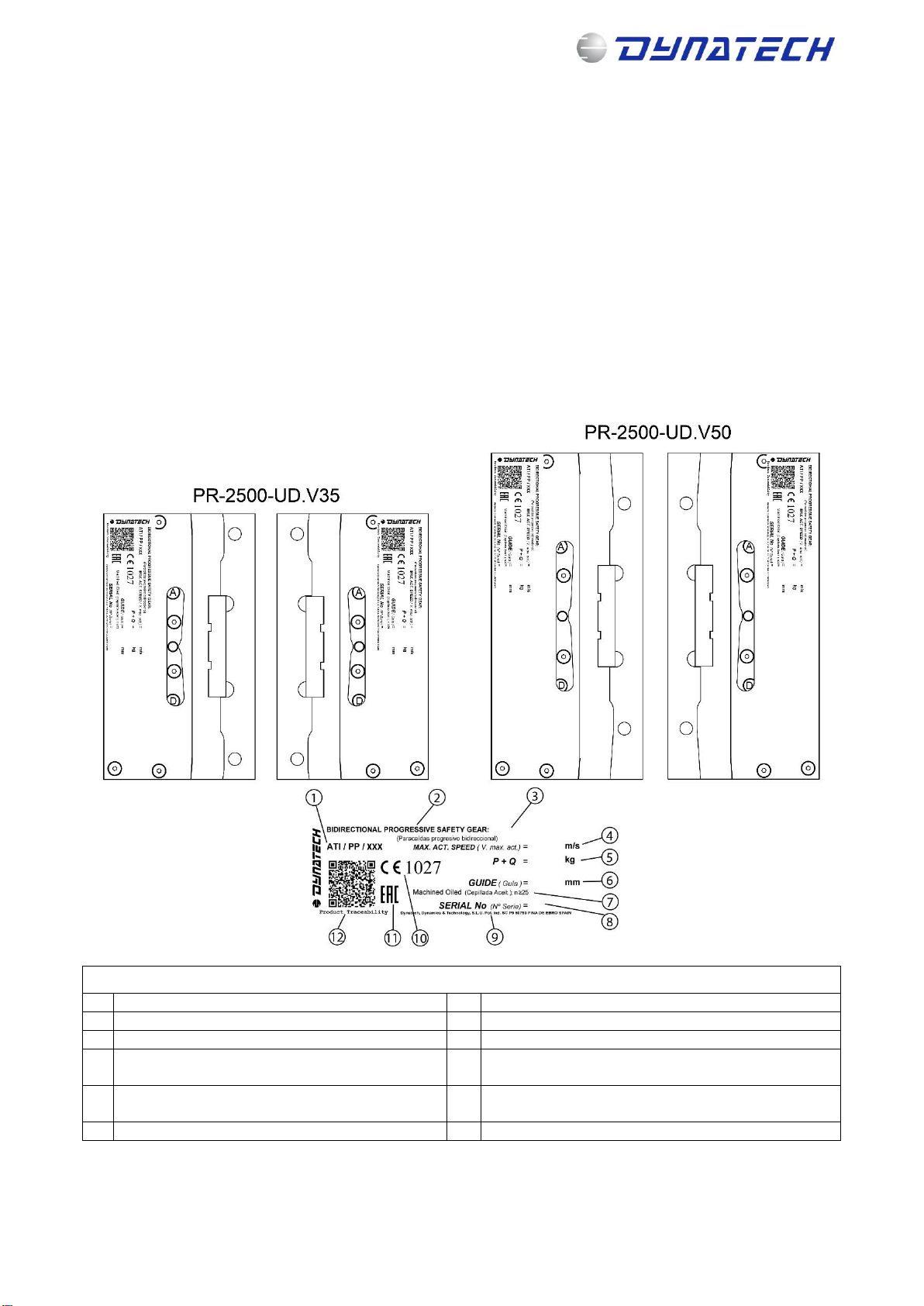

2SAFETY GEAR IDENTIFICATION AND CHARACTERISATION ................................................................................... 3

2.1 IDENTIFICATION .................................................................................................................................................. 3

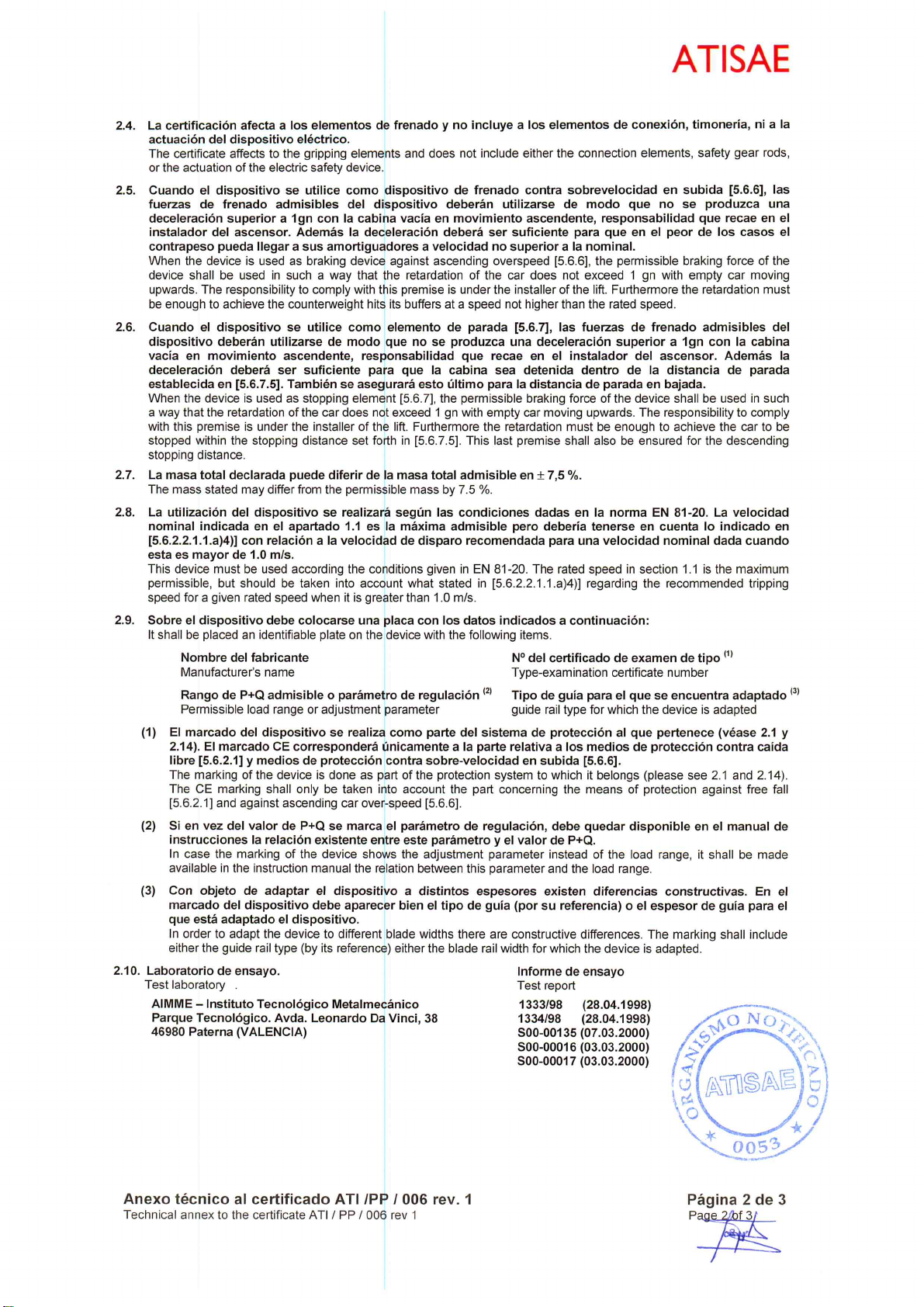

2.2 SAFETY GEAR’S FEATURES AND USE .................................................................................................................... 4

2.3 RANGE OF USE..................................................................................................................................................... 4

3INSTALLATION AND ADJUSTMENT ...................................................................................................................... 4

3.1 ASSEMBLY ON THE FRAME .................................................................................................................................. 4

3.2 SAFETY GEAR ADJUSTMENT ................................................................................................................................ 6

3.3 COUPLING THE DRIVING BAR .............................................................................................................................. 7

3.3.1 USING DYNATECH’S T-2 DRIVING BAR ........................................................................................................ 7

3.3.2 USING DYNATECH’S T-3 DRIVING BAR ........................................................................................................ 8

4INSPECTIONS AND MAINTENANCE...................................................................................................................... 8

4.1 CHECKING THE SAFETY GEARS ............................................................................................................................ 8

4.2 PRECAUTIONS ..................................................................................................................................................... 9

4.3 MAINTENANCE.................................................................................................................................................... 9

4.3.1 LIST OF MAINTENANCE OPERATIONS ......................................................................................................... 9

4.3.2 CORROSION................................................................................................................................................. 9

4.4 STORAGE AND SERVICE LIFE ................................................................................................................................ 9

5UCM...................................................................................................................................................................10

5.1 UCM SYSTEM’S PRELIMINARY DESIGN. ............................................................................................................. 10

5.2 SAFETY GEAR BRAKING DISTANCE CALCULATION ............................................................................................. 10

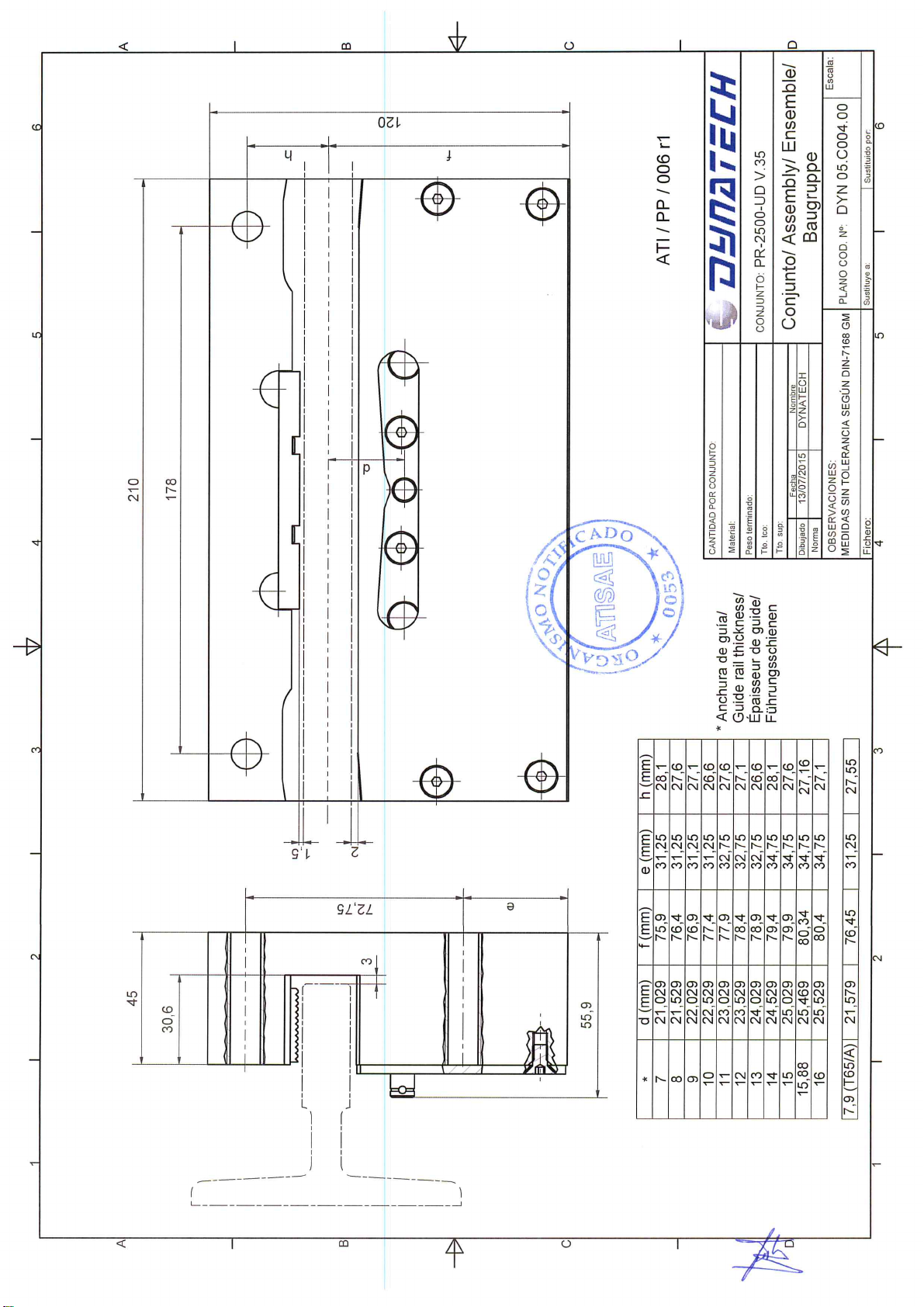

6GENERAL DRAWING ...........................................................................................................................................10

_____________________________________________________