B3 ESS Unit User Manual

I

Content

Statement of Law .....................................................................................................................................1

Safety Precautions.................................................................................................................................... 2

Preface...................................................................................................................................................... 3

1 Introduction.......................................................................................................................................... 4

1.1 Brief Introduction..........................................................................................................................4

1.2 Product Properties........................................................................................................................4

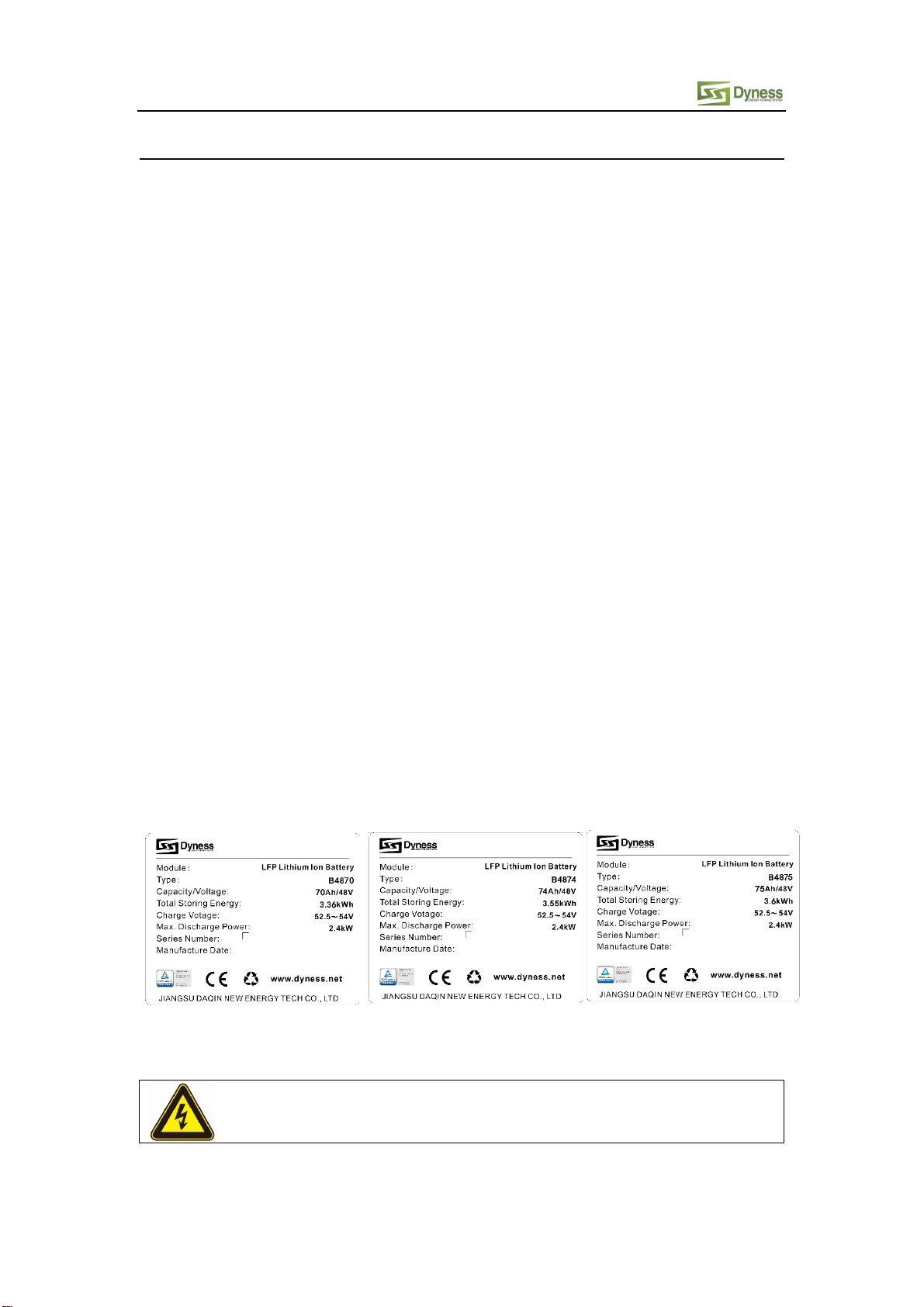

1.3 Product identity definition............................................................................................................4

2 Product Specification............................................................................................................................6

2.1 Size and Weight ............................................................................................................................6

2.2 Performance Parameter ...............................................................................................................6

2.3 Interface Definition....................................................................................................................... 6

2.3.1 DIP switch definition and description ....................................................................................7

2.4Battery Management System(BMS) ...........................................................................................10

2.4.1 Voltage Protection ..............................................................................................................10

2.4.2 Current Protection ..............................................................................................................10

2.4.3 Temperature Protection .....................................................................................................10

2.4.4 Other Protection ................................................................................................................. 11

3 Installation and Configuration ............................................................................................................12

3.1 Ready for installation..................................................................................................................12

3.1.1 Environmental requirements ..............................................................................................12

3.1.2 Tools and data.....................................................................................................................12

3.1.3 Technical preparation .........................................................................................................13

3.1.4 Unpacking inspection..........................................................................................................13

3.1.5 Engineering coordination....................................................................................................13

3.2 Equipment installation................................................................................................................14

3.2.1 Installation preparation .......................................................................................................15

3.2.2 Mechanical installation ........................................................................................................15

3.2.3 Electrical installation ...........................................................................................................16

4 Use, maintenance and troubleshooting .............................................................................................18

4.1 Battery system usage and operation instructions ......................................................................18

4.2Alarm description and processing...............................................................................................18

4.3Analysis and treatment of common faults..................................................................................19