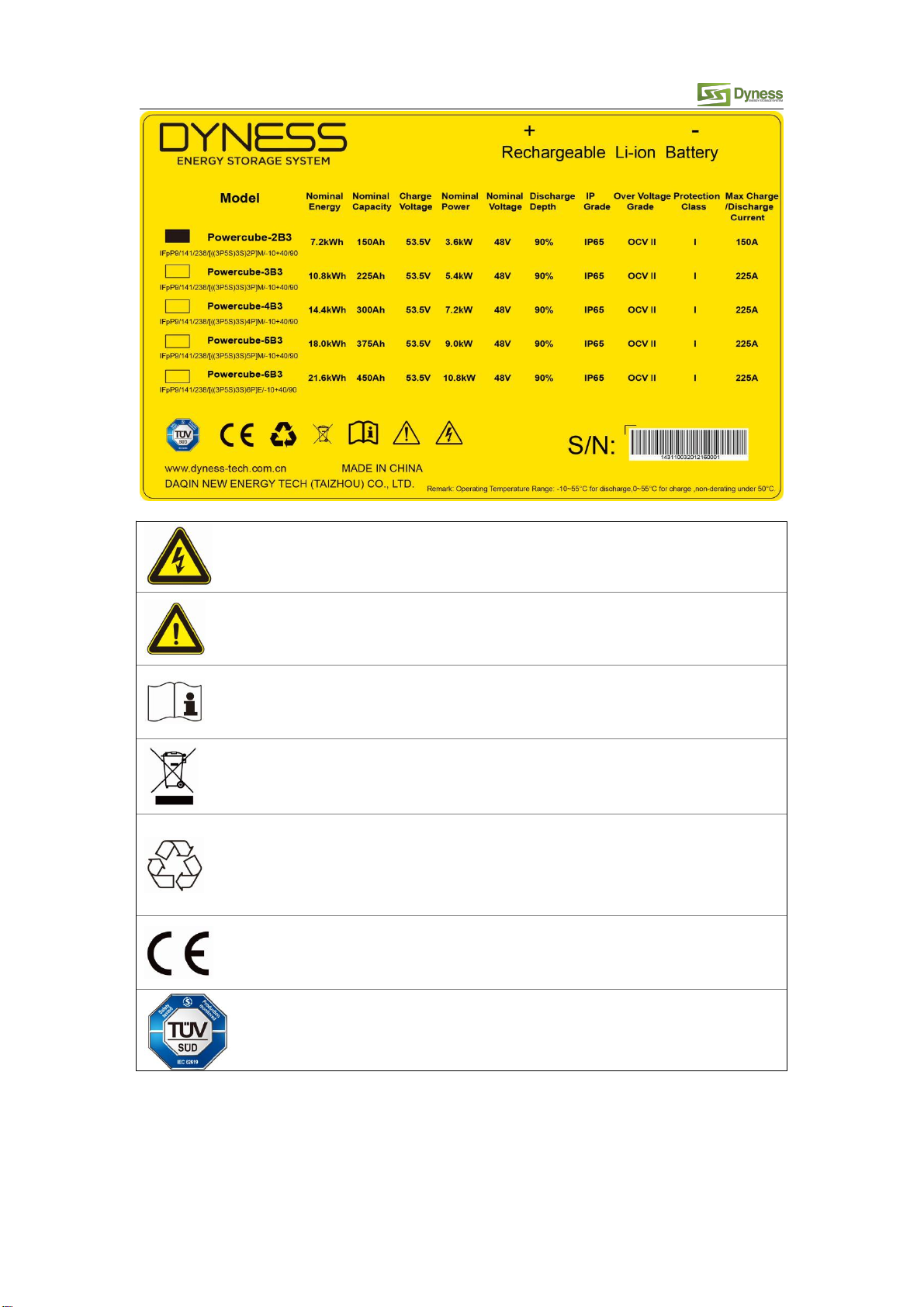

POWERCUBE User Manual

Safety Precautions and maintenance instructions

Warning

Please do not put the battery into water or fire, in case of explosion or any other

situation that might endanger your life.

Please connect wires properly while installation, do not reverse connect.

To avoid short circuit, please do not connect positive and negative poles with

conductor (Wires for instance).

Please do not stab, hit, trample or strike the battery in any other way.

Please shut off the power completely when removing the device or reconnecting wires

during the daily use or it could cause the danger of electric shock.

Please use dry powder extinguisher to put out the flame when encountering a fire

hazard, liquid extinguisher could result in the risk of secondary disaster.

For your safety, please do not arbitrarily dismantle any component in any

circumstances unless a specialist or an authorized one from our company, device

breakdown due to improper operation will not be covered under warranty.

Caution

We have strict inspection to ensure the quality when products are shipped out,

however, please contact us if case bulging or another abnormal phenomenon.

For your safety, device shall be ground connected properly before normal use.

To assure the proper use please make sure parameters among the relevant device are

compatible.

Please do not mixed-use batteries from different manufacturers, different types and

models, as well as old and new together.

Ambient and storage method could impact the life span and product reliability, please

consider the operation environment abundantly to make sure device works in proper

condition.

For long-term storage, the battery should be recharged once every 6 months, and the

amount of electric charge shall exceed 80% of the rated capacity.

Please charge the battery in 18 hours after it discharges fully and starts over-discharging

protection.

Formula of theoretical standby time: T=C/I (T is standby time, C is battery capacity, I is

total current of all loads).

The product is affixed with a torn invalid label before leaving the factory. If anyone

need to open the cover to operate, such as set DIP mode, expand the capacity or

other operations that won’t harm the product, customer needs to contact DYNESS

and inform the product ID. DYNESS will record the case, confirm the operation can be

operated and will authorize. After the authorization, only professionals are allowed to