B4850 ESS Unit User Manual

I

Content

STATEMENT OF LAW ..................................................................................................................................... 1

SAFETY PRECAUTIONS................................................................................................................................... 2

PREFACE.......................................................................................................................................................... 3

1 INTRODUCTION.......................................................................................................................................... 4

1.1 BRIEF INTRODUCTION.............................................................................................................................................4

1.2 PRODUCT PROPERTIES............................................................................................................................................4

1.3 PRODUCT IDENTITY DEFINITION ..............................................................................................................................4

2 PRODUCT SPECIFICATION ......................................................................................................................... 6

2.1 SIZE AND WEIGHT...................................................................................................................................................6

2.2 PERFORMANCE PARAMETER...................................................................................................................................6

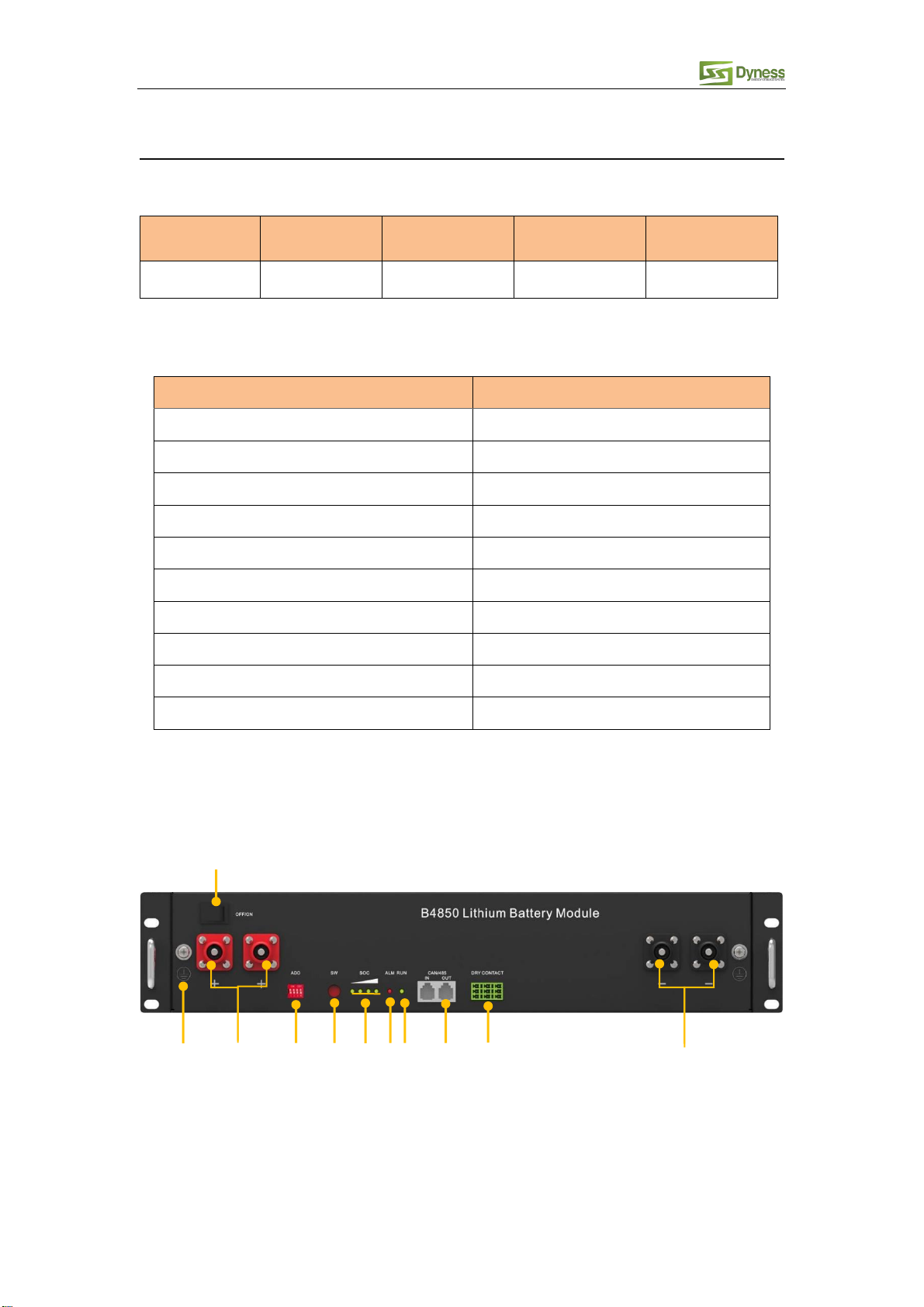

2.3 INTERFACE DEFINITION ...........................................................................................................................................6

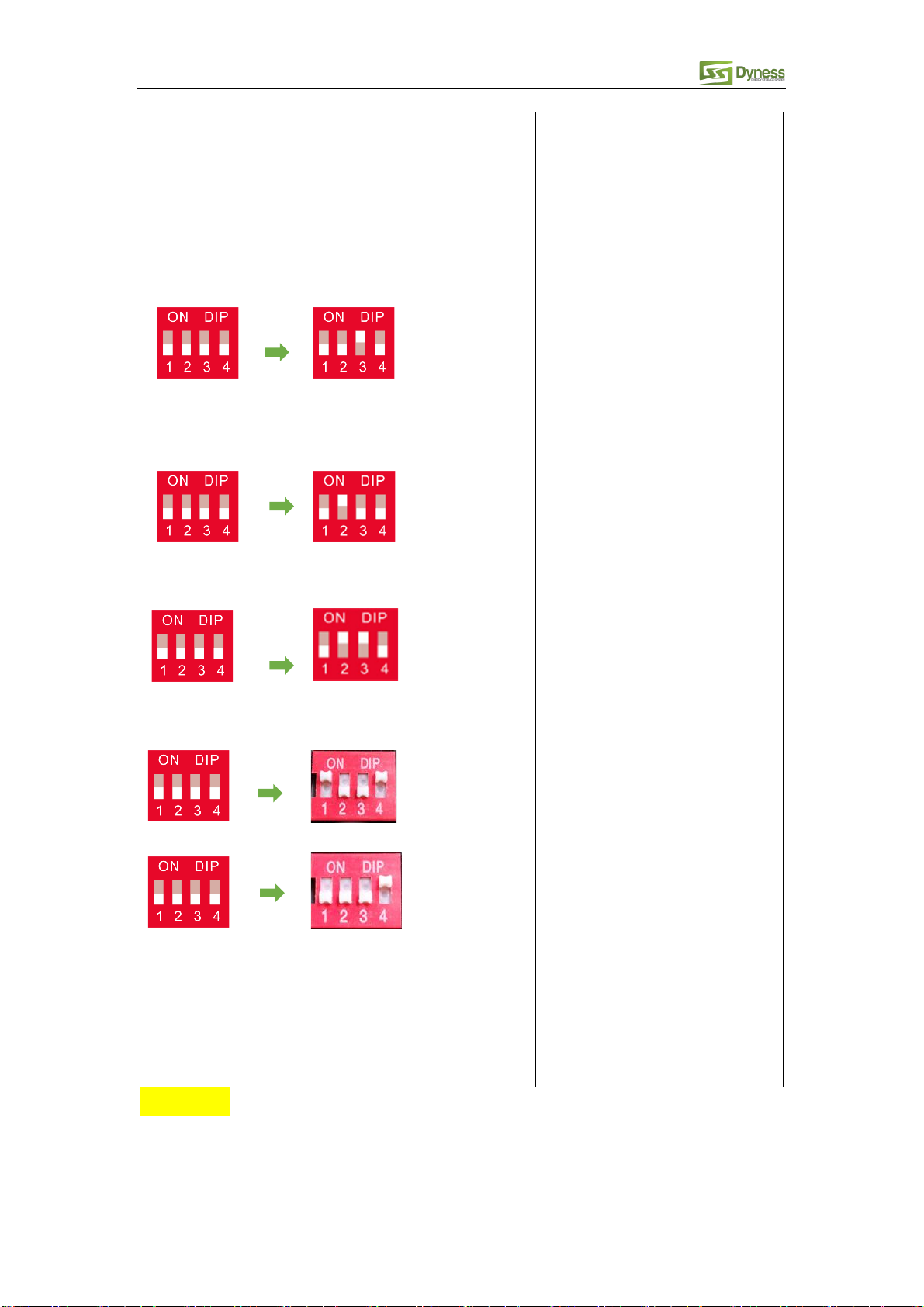

2.3.1 DIP switch definition and description

...................................................................................................7

2.4 BATTERY MANAGEMENT SYSTEM(BMS)............................................................................................................ 10

2.4.1 Voltage Protection

................................................................................................................................ 10

2.4.2 Current Protection

................................................................................................................................. 10

2.4.3 Temperature Protection

...................................................................................................................... 11

2.4.4 Other Protection

.................................................................................................................................... 11

3 INSTALLATION AND CONFIGURATION .................................................................................................. 11

3.1 READY FOR INSTALLATION ................................................................................................................................... 11

3.1.1 Environmental requirements

.............................................................................................................. 12

3.1.2 Tools and data

....................................................................................................................................... 12

3.1.3 Technical preparation

.......................................................................................................................... 12

3.1.4 Unpacking inspection

........................................................................................................................... 13

3.1.5 Engineering coordination

.................................................................................................................... 14

3.2EQUIPMENT INSTALLATION.................................................................................................................................. 15

3.2.1 Installation preparation

........................................................................................................................ 15

3.2.2 Mechanical installation

......................................................................................................................... 15

3.2.3 Electrical installation

............................................................................................................................ 16

3.2.4 Battery parameter settings on the inverter

.................................................................................... 18

3.2.5 Register on the website after installation

....................................................................................... 18

4 USE, MAINTENANCE AND TROUBLESHOOTING ................................................................................... 19

4.1 BATTERY SYSTEM USAGE AND OPERATION INSTRUCTIONS ..................................................................................... 19

4.2ALARM DESCRIPTION AND PROCESSING............................................................................................................... 20

4.3ANALYSIS AND TREATMENT OF COMMON FAULTS ............................................................................................... 21