5

SAFETY

2.2.

2.2.

2. NN

NN

NOO

OO

OTETE

TETE

TESS

SS

S

ONON

ONON

ON

SS

SS

SAFETAFET

AFETAFET

AFETYY

YY

Y

The operator or owner of the larger overall system is responsible for following the safety

and accident prevention regulations that apply to the specific application.

When planning machinery and using the PT, follow the safety and accident prevention

regulations that apply to your application, e.g.:

• EN 60204, Electrical equipment in machines.

• EN 292, Machine safety, general design guidelines.

• DIN 57 100 Part 410, Protection against electric shock.

• EN 50 014:1997, General Requirements

• EN 50 020:1994, Intrinsically safe apparatus

• EN50284:1999, Special requirements fro Group II Category 1G

Mounting and electrical connection of the PT must be done by specialists with EMC training,

following all applicable regulations, and in pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safepressureless, voltage-free, intrinsically safe

pressureless, voltage-free, intrinsically safe

condition with the machine switched offmachine switched off

machine switched offmachine switched off

machine switched off.

The mThe m

The mThe m

The macac

acac

achine muhine mu

hine muhine mu

hine muss

ss

stt

tt

tbe secbe sec

be secbe sec

be securur

urur

ured aged ag

ed aged ag

ed againain

ainain

ainss

ss

stt

tt

tbeinbein

beinbein

being swg sw

g swg sw

g switit

itit

itcc

cc

ched bhed b

hed bhed b

hed bacac

acac

ackk

kk

kon!on!

on!on!

on!

Ambient temperature for the electronics housing mm

mm

max. +80°Cax. +80°C

ax. +80°Cax. +80°C

ax. +80°C (safety class T4 max.).

Higher temperatures can result in damage and malfunction. Do not install the pressure

transmitter in places where this temperature is exceeded.

ExpExp

ExpExp

Explolo

lolo

loss

ss

sion hion h

ion hion h

ion hazaz

azaz

azarar

arar

ard!d!

d!d!

d!

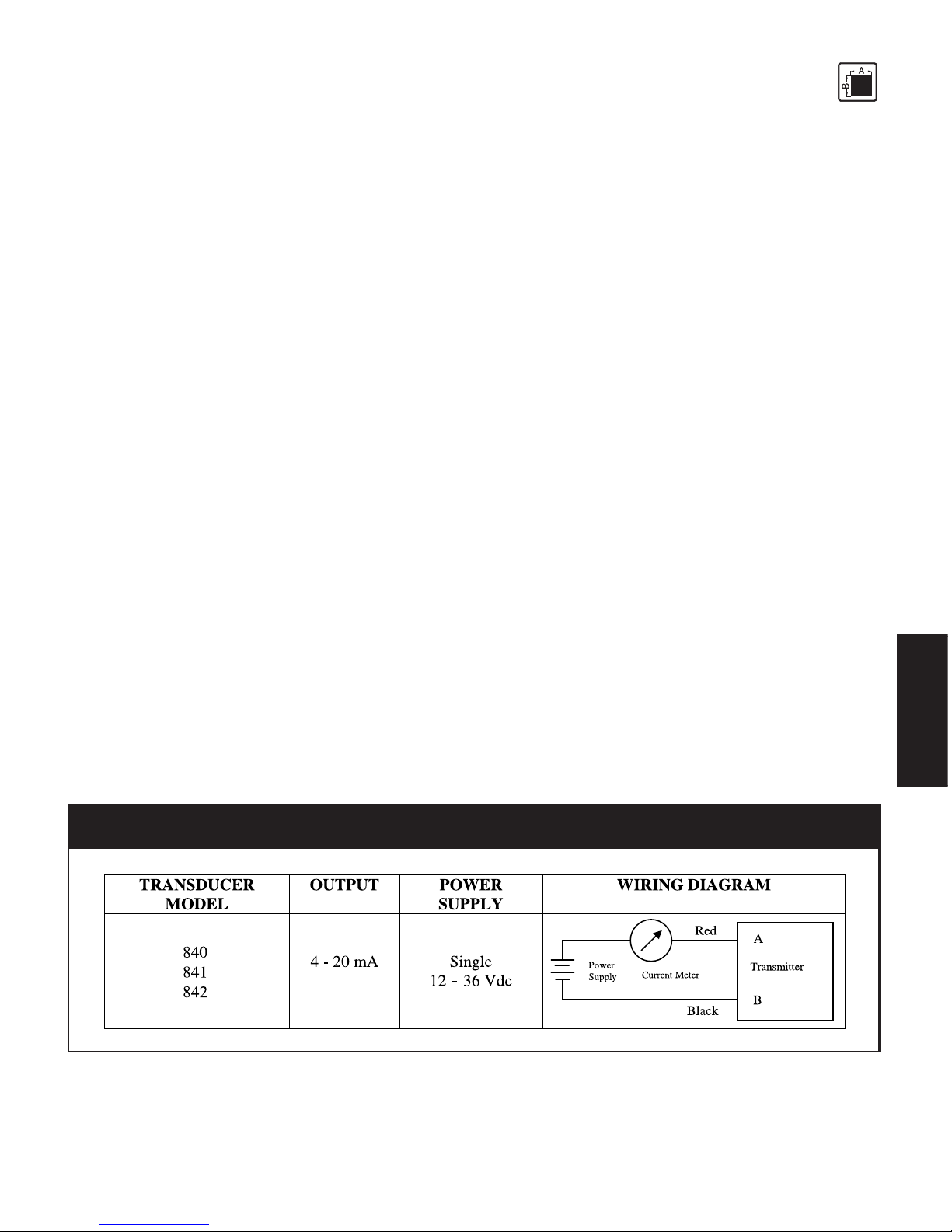

Deviation of the supply voltage from the value given in the technical specifications, or

false polarity, can damage the pressure transmitter and cause malfunctions that can

pose a risk of explosion.

Operate only with an intrinsically safe, EMC compliant power supply with the

following specifications when employing the pressure 4-20mA output:

Supply voltage max.40 V DC

Current output max. 100 mA

Inductivity max. 0

Capacity max. 0.017 µF

For PT’s that are explosion proof Class I, Division 1, Groups A, B, C & D, the power

supply rating is 16-40 Vdc.

Do not lay connecting cables in the direct vicinity of cables carrying higher voltage or

used to switch inductive or capacitive loads.