E.J. Ozone Products ME800 series User manual

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS

(様式 EO-H0523-10)

INSTRUCTION MANUAL

Installation-type Ozone Analyzer

Model ME800 series

High Concentration Ozone Analyzer ME810 (Type S / Type R)

Off-gas Ozone Analyzer ME820 Type S

Published on January 24, 2017

EBARA JITSUGYO CO., LTD.

MEASURING INSTRUMENT

AND MEDICAL DIVISION

EAST JAPAN SALES DEPARTMENT:

WEST JAPAN SALES DEPARTMENT:

RESEARCH AND DEVELOPMENT DEPARTMENT:

2-3-12 Kurigi, Asao-ku, Kawasaki-shi,

Kanagawa, 215-0033 JAPAN

Tel: +81-44-981-0560 Fax: +81-44-981-0561

3-2-13, Hiranocho, Chuo-ku, Osaka-shi,

Osaka, 541-0046 JAPAN

Tel: +81-6-6231-3528 Fax: +81-6-6231-2929

2-3-12 Kurigi, Asao-ku, Kawasaki-shi,

Kanagawa, 215-0033 JAPAN

Tel: +81-44-981-0560 Fax: +81-44-981-0561

E-mail e

j

ozndsn1

@

e

j

k.co.

jp

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 1 -

Introduction

Thank you for purchasing our ME800-series ozone analyzer. The ME800-series analyzers are

operable in two models: one for measuring generated ozone, and the other for measuring off-gas

ozone. Select an appropriate one depending on your intended use.

This instruction manual is edited in order to use it correctly and also to apply its special features to

the maximum extent. And then, in notice and each item, the important messages are described, so

please be sure to read this manual before using the analyzer.

About this instruction manual

(a) This manual is necessary when the analyzer is used or when its maintenance is performed.

Please always keep this manual handy so that you can use it at any time.

(b) When you have lost or stained the manual, please order it from our company or our sales agency

and get it.

(c) If this manual has a defect such as incorrect collation or missing page, and also when there is a

suspicion of a mistake or an omission in this content, please inform our company or our sales

agency of this problem.

(d) Regarding figures and screen in the manual or on the product labels, omission is conducted

partly on the grounds that they can be understood easily, so please note that in advance.

(e) Contents of this manual may have to be changed without announcement for improvement of the

products, so please note that in advance.

(f) Author’s right (copyright) of this manual is reserved by Ebara Jitsugyo Co., Ltd. Do not open all

or a part of this manual to third persons in the public without permission of our company.

Composition of the product

The composition of the analyzer is as shown below. Check the model and type of the ozone analyzer

you purchased as well as the details of the composition. Note that optional parts for which you

placed the order with your dealer are included.

Model and type of the ozone analyzer

High Concentration

Ozone Analyzer

........... ME810 Type S: Automatic calibration integrated in

Ozone scrubber

........... ME810 Type R: External zero gas supply type

automatic calibration

Off-gas Ozone Analyzer ........... ME820 Type S: External zero gas supply type

automatic calibration

Delivery

The analyzer is delivered in a state as described below. On receiving the product, check to make

sure that none of the following components is missing.

High Concentration Ozone Analyzer supply list

(1) Basic composition (Common to ME810-series products)

Item Classification Product name Quantity Note

(Model, product code, etc.)

1 Product

High Concentration

Ozone Analyzer 1 unit ME810 (Type S / Type R)

2 Accessories Fuse 2 pcs.

250 V, 1.25 A AC: EF012A

(Rush-resistant type,

UL/CSA/PSE-compliant)

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 2 -

3 Accessories

Filter/valve assembly

1 set

(*1)

• 1/4 inch: BZ178A

• 3/8 inch: BZ178B

• Ø6 m/m: BZ178C

• Ø10 m/m: BZ178D

• Needle valve

• Stainless filter holder

• Needle valve/bracket, etc.

• Sample gas port coupling

(*1)

4 Document Instruction manual 1 copy EOP-***-***-

(See reference No.)

5 Document Test report 1 copy See product S/N.

Contact your dealer if all the components are not supplied.

Place an order with your dealer if any lost or contaminated items should be found after the

purchase.

*1: The coupling (Swagelok®) is a selectable accessory, which is mounted to the filter/valve

assembly.

(2) Accessories for external zero gas

Item Classification Product name Quantity Note

(Model, product code, etc.)

6 Accessories

Zero gas/valve assembly

(1 set)

(*1)

• 1/4 inch/Ø6 m/m: BZ179A

• 3/8 inch/Ø10 m/m: BZ179B

• Needle valve for zero gas

• Filter for zero gas

(transparent)

• Silencer

• Zero gas valve/bracket,

etc.

• Zero gas port coupling

(*1)

Accessories for external zero gas are packed for ME810 Type R only.

*1: The coupling (Flowell®) is a selectable accessory, which is mounted to the zero gas/valve

assembly.

(3) Optional parts (Common to ME810-series products)

Item Classification Product name Quantity Note

(Model, product code, etc.)

7 Option

Enclosure-mount Ozone

destruct

• Enclosure-mount Ozone

destruct

• Connection coupling

• Ozone destruct cover

(1 set) BZ324A

8 Option

External Ozone destruct

• External Ozone destruct

• Sample gas port coupling

(1 set) (*1)

• 1/4 inch: BZ325A

9 Option Roof assembly (1 set) BZ627A

Only the optional parts you requested are supplied.

*1: Swagelok®coupling

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 3 -

Off-gas Ozone Analyzer supply list

(1) Basic composition

Item Classification Product name Quantity Note

(Model, product code, etc.)

1 Product Off-gas Ozone Analyzer 1 unit ME820 Type S

2 Accessories Fuse 2

250 V, 1.25 A AC: EF012A

(Rush-resistant type,

UL/CSA/PSE-compliant)

3 Accessories

Water trap assembly

(Coalesced)

1 set

(*1)

For 3/8 inch, Ø10 mm:

BZ262A

For switching between

1/4 and 3/8 inch: BZ262B

For switching between

5/16 and 3/8 inch: BZ262C

• Water trap

• Drain valve

• Water trap bracket

• Water trap stopper

• Mounting band attached

with rubber sheet

• Sample gas port coupling

(*1)

4 Document Instruction manual 1 copy EOP-***-***-

(See reference No.)

5 Document Test report 1 copy See product S/N.

Contact your dealer if all the components are not supplied.

Place an order with your dealer if any lost or contaminated items should be found after the

purchase.

*1: The coupling (Flowell®) is a selectable accessory, which is mounted to the water trap

assembly.

(2) Optional parts

Item Classification Product name Quantity Note

(Model, product code, etc.)

6 Option

External Ozone destruct

• Sample gas port coupling (1 set) (*1) • 1/4 inch: BZ325A

(*2) • 3/8 inch: BZ325B

7 Option Roof assembly (1 set) BZ627A

Only the optional parts you requested are supplied.

*1: Swagelok®coupling

*2: Flowell®coupling

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 4 -

Maintenance parts

Use the genuine replacement parts listed below by placing an order with your dealer.

* The use of parts other than the genuine ones may result in a failure, which is not covered by the

warranty.

Maintenance parts list

Subject

product Parts name Product

code Quantity Note

Common

Lamp unit BZ107A 1 set Low-pressure mercury lamp

Fuse EF012A 2 pcs.

250 V, 1.25 A AC:

(Rush-resistant type,

UL/CSA/PSE-compliant)

High

Concentration

Ozone

Analyzer

(ME810)

3-way solenoid valve

assembly BZ140B 1 pc. —

Filter element NF037A 1 pc.

Filter O-ring NO039A 1 pc. (Ozone-resistant)

Flowmeter

(1 L/min) NR024A 1 pc. —

Ozone scrubber (*3) BZ326A 1 pc. With coupling (tube fittings)

(Swagelok®)

Zero gas filter NF008A 1 pc. (External color: Transparent)

(For ME810 Type R only)

Enclosure-mount

Ozone destruct

(Optional parts)

BZ324B 1 pc.

With coupling

(Without cover for Ozone

destruct)

External Ozone destruct

(Optional parts) BZ325A 1 pc.

With coupling

(*1) • 1/4 inch

Off-gas

Ozone

Analyzer

(ME820)

3-way solenoid valve

assembly

BZ144A

1 pc.

With coupling/pipe

(Standard)

BZ144B

With coupling/pipe

(For mounting of an optional

pressure sensor)

Sample gas filter NF012A 1 pc. (External color: Blue)

Zero gas filter NF008A 1 pc. (External color: Transparent)

Sample gas pump

assembly BZ405A 1 pc. With rubber cushion

Membrane dryer EU022A 1 pc. —

Flowmeter assembly

(2L/min) BZ159A 1 pc. With coupling

Ozone destruct (*3) BZ326B 1 pc.

With coupling

(Quick-Fitting Joint)

(PISCO®)

External Ozone destruct

(Optional parts) BZ325 1 pc.

With coupling

(Select *1 or *2)

*1: 1/4inch:BZ325A

*2: 3/8inch:BZ325B

*1: Swagelok®coupling

*2: Flowell®coupling

*3: Contact us for the set of ozone decomposing catalyst (BZ327A).

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 5 -

To ensure your safety

Please refer to “Marks and descriptions”, “Biological influences caused by Ozone”, “Dangerous

characteristics for ozone treatment”, “Cautions on operating the analyzer”, and “Cautions on the

low-pressure mercury lamp” shown below.

Marks and descriptions

Note 1: Serious injury includes loss of sight, high-temperature/low-temperature burn, electric shock,

bone fracture, and poisoning, and involves aftereffects or requires hospitalization or hospital

visit for a long period of time for medical treatment.

Note 2: Minor or moderate injury includes burn, electric shock, etc. that do not require

hospitalization or hospital visit for a long period of time for medical treatment. Property

damage is defined as extended damage resulting from loss of properties and damage to

equipment.

Mark Description

DANGER DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

DANGER

ELECTRIC

SHOCK

DANGER ELECTRIC SHOCK indicates places where electric

shock may result unless sufficient caution is exercised.

CAUTION

UV RAY

CAUTION UV RAY indicates places where your eyes and skin

may be damaged unless sufficient caution is exercised.

CAUTION

HIGH TEM-

PERATURE

CAUTION HIGH TEMPERATURE indicates places where burn,

etc. may result unless sufficient caution is exercised.

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 6 -

■ Biological influences caused by Ozone

Ozone concentration

[ppm] Influences

0.01–0.02 Sensible odor (with the sense of smell becoming gradually accustomed to

the smell)

0.1 Strong odor stimulant to the nose and throat.

0.2–0.5 Eyesight weakens by 3 to 6 hour's exposure.

0.5 Apparently stimulant to the upper respiratory tract.

1–2

Exposure for 2 hours presents a headache, a pain in the chest, and thirsty at

the upper respiratory tract and coughing.

Repeatable exposures will lead to chronic toxicities.

5–10 Increase of pulses and pulmonary edema will be caused.

15–20 Small animals will die within 2 hours.

50 Life of man will be jeopardized in one hour.

Report on Ozone Processing' by Japan Water Works Association, August 1984, p. 40

Threshold limit value:

Japan : 0.1 [ppm] (recommendation by Japan Society for Occupational Health)(2010-2011)

USA : 0.1 [ppm] TLV of TWA by ACGIH (1993–1994)

TLV : Threshold limit value

TWA : Time Weighted Average Concentration

ACGIH : American Conference of Governmental Industrial Hygienists

■ Dangerous characteristics for Ozone treatment

DANGER

Ozone has powerful oxidation effect, and it is used for many kinds of substance by the reaction,

such as Oxidation/Dissolution, Sterilization, etc., but it is also informed that Ozone has

'Toxicity' for human bodies.

Therefore, precautions should be taken to any exposure to Ozone leakage on the piping

connections for Ozone sampling system and/or the wetted parts, and also the related

equipments.

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 7 -

■ Cautions on operating the analyzer

DANGER

This analyzer is not constructed by standard of explosion proof.

If you use the analyzer in the place where combustible gas or inflammable gas is floating in

the environment, this can cause explosion. Do not use the analyzer surely in these places.

WARNING

If there is Ozone smell, check whether the ozone analyzer is in an abnormal condition such

as piping damage and slackness on the joint.

High voltage power supply (Steady state: about 200 V AC and Starting state: about 1000 V

AC in a moment) for the mercury lamp is built in the analyzer, so that you may have an

electrical shock when performing adjustment and repairing inside of the analyzer. Let a

specialist perform it.

If the front door is opened with the power kept ON, UV ray emitted from the mercury lamp

blinking inside may cause damage to your eyes or skin. Do not see the UV ray with the

low-pressure mercury lamp kept ON. When working near the low-pressure mercury lamp, be

sure to wear protective glasses.

When ozone is fed to the Ozone scrubber / Ozone destruct (optional Ozone destruct), the

surface temperature increases. Be careful not to touch the surface.

Be sure to turn off the power of the analyzer before replacing parts.

Clean the analyzer at the time of periodic maintenance (maintenance/inspection). Before

cleaning the analyzer, be sure to turn off the main power and the power switch, and clean the

analyzer using dry cloth.

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 8 -

CAUTION

This analyzer is a precision instrument. Do not affect a shock and/or vibration to this

analyzer.

Regarding accident and trouble that have happened as a result of remodeling or modifying

the analyzer, we cannot take the responsibility, even if it is in the warranty term.

Never introduce a sample which has higher pressure than the specification limit into the

analyzer. This would cause a leak or trouble. To read the specification and also to perform

routine inspection are needed.

In case that the analyzer is removed from the related device for maintenance, be sure to

confirm that ozone is not residual in the inside of analyzer and the connected pipes, and then

work after turning off the power supply. Still more, turn off the power supply surely for

replacing the parts.

If the sample gas contains materials except ozone, such as hydrogen fluoride and moisture,

the inner part of the analyzer which is exposed to gas may be eroded, damaged, clouded or

rusted. In case that the analyzer has trouble and cannot measure ozone by the influence of

other material than ozone, note that the analyzer will not be guaranteed, even if it is in the

warranty term.

The analyzer should be used after complete installation.

The parts used inside of the analyzer have the end of their life. Continuing to use them after

replacement time may lead to the failure of the other parts. Conduct their maintenance

periodically.

■ Cautions on the low-pressure mercury lamp

CAUTION

This analyzer uses a low-pressure mercury lamp for a light source, and this lamp contains

harmful component to the humans. Therefore, the used lamp as consumable part should be

scrapped in accordance with your local regulation.

Do not drop the low-pressure mercury lamp, do not throw a thing against it, do not apply

load to it and do not stress or scratch it, because it is a glass product.

Avoid pulling lead wire of the lamp kit excessively or adding impact more than 981m/S2,

because it may sometimes lead to making the lamp unable to light.

Do not touch a broken lamp with hands directly. If you touched it, wash with tap water what

was attached to the hands and after that, wash again with soap thoroughly.

Do not touch the lamp or its terminals and the stripped wire, because this lamp is lighting

with high voltage. This can cause electric shock.

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 9 -

Contents

1. General description........................................................................................................................13

2. Measuring principle .......................................................................................................................13

3. Specifications ................................................................................................................................14

4. Names of each part and description of functions ............................................................................19

5. Function ........................................................................................................................................25

5.1 Names of parts of the indicator and their functions .................................................................25

5.2 Operation function of the indicator .........................................................................................27

5.2.1 Measurement mode ..........................................................................................................27

5.2.2 Setting mode ....................................................................................................................28

5.2.3 Check mode .....................................................................................................................37

5.2.4 Test mode.........................................................................................................................38

5.3 Panel lock function.................................................................................................................39

5.4 Zero calibration ......................................................................................................................39

5.5 Lamp heater ...........................................................................................................................42

5.6 Other functions.......................................................................................................................42

5.6.1 Temperature compensation function .................................................................................42

5.6.2 Pressure compensation function (Optional).......................................................................43

6Installation conditions and installation method ..............................................................................43

6.1 Installation conditions ............................................................................................................43

6.2 Preparation for installation .....................................................................................................44

6.2.1 Preparation for installation of High Concentration Ozone Analyzer ..................................44

6.2.2 Preparation for installation of Off-gas Ozone Analyzer.....................................................45

6.2.3 Mounting the common optional accessories (Optional parts) ............................................46

6.3 Installation .............................................................................................................................47

6.4 Wiring ....................................................................................................................................48

6.4.1 Connecting the power cable..............................................................................................48

6.4.2 Connecting the control cable ............................................................................................50

6.4.3 Connecting the signal cable..............................................................................................52

6.5 Piping method ........................................................................................................................54

6.5.1 Piping method of High Concentration Ozone Analyzer .....................................................54

6.5.2 Piping method of Off-gas Ozone Analyzer........................................................................55

6.5.3 Removing the pipes..........................................................................................................56

7. Measurement procedure .................................................................................................................56

7.1 Preparation for measurement ..................................................................................................56

7.2 Measurement ..........................................................................................................................58

7.3 Restarting...............................................................................................................................58

7.4 Storage ...................................................................................................................................58

8. Span calibration.............................................................................................................................58

9. Maintenance and inspection ...........................................................................................................59

9.1 Daily inspection .....................................................................................................................59

9.2 Periodic inspection .................................................................................................................60

9.3 Periodic replacement parts......................................................................................................60

9.4 Other replacement parts..........................................................................................................61

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 10 -

9.5 How to replace parts...............................................................................................................63

9.5.1 How to replace the lamp unit............................................................................................63

9.5.2 How to adjust the sensor ..................................................................................................64

9.5.3 How to replace the fuses ..................................................................................................64

9.5.4 How to replace the 3-way solenoid valve..........................................................................65

9.5.5 How to replace the sample gas pump (Off-gas Ozone Analyzer only) ...............................67

9.5.6 How to replace the Ozone scrubber and Ozone destruct....................................................68

9.5.7 How to replace the filter...................................................................................................69

9.5.8 How to replace the flowmeter...........................................................................................71

9.5.9 How to replace the membrane drier (for Off-gas Ozone Analyzer only) .........................72

9.5.10 How to replace the Ozone destruct (for enclosure-mount unit)..........................................73

10. Error display..................................................................................................................................73

10.1 Self-diagnostic error display...................................................................................................73

10.2 Self-diagnostic alarm display..................................................................................................76

10.3 Setting error ...........................................................................................................................76

10.4 Error and alarm display ..........................................................................................................77

11. Model code....................................................................................................................................78

12. Warranty .......................................................................................................................................80

Figure

Figure- 1 Logic Diagram ..................................................................................................................13

Figure- 2 Names of each part of ME810 Type S................................................................................19

Figure- 3 Names of each part of ME810 Type R ...............................................................................20

Figure- 4 Names of each part of ME820 Type S................................................................................21

Figure- 5 Names of parts of the indicator..........................................................................................25

Figure- 6 How to change modes .......................................................................................................27

Figure- 7 Typical setting mode transition..........................................................................................28

Figure- 8 Typical check mode transition ...........................................................................................37

Figure- 9 Typical test mode transition ..............................................................................................38

Figure- 10 Zero calibration timing chart ...........................................................................................40

Figure- 11 Interval time timing chart ................................................................................................41

Figure- 12 Manual operation timing chart.........................................................................................41

Figure- 13 Auto zero calibration timing chart ...................................................................................42

Figure- 14 Lamp heater switch .........................................................................................................42

Figure- 15 Filter/valve assembly ......................................................................................................44

Figure- 16 Zero gas/valve assembly..................................................................................................44

Figure- 17 Enclosure-mount Ozone destruct .....................................................................................45

Figure- 18 Water trap assembly ........................................................................................................45

Figure- 19 Sample gas pump fixing bracket ......................................................................................45

Figure- 20 Roof assembly.................................................................................................................46

Figure- 21 Maintenance space ..........................................................................................................47

Figure- 22 Mounting bracket ............................................................................................................48

Figure- 23 Power cable wiring..........................................................................................................49

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 11 -

Figure- 24 Power terminal block (TB1) ............................................................................................49

Figure- 25 Treatment of power cable ................................................................................................50

Figure- 26 Control cable wiring........................................................................................................50

Figure- 27 Treatment of control cable...............................................................................................51

Figure- 28 Analyzer output terminal block (TB1) .............................................................................51

Figure- 29 Wiring of signal cable .....................................................................................................52

Figure- 30 Treatment of signal cable ................................................................................................52

Figure- 31 Analog output/analyzer input terminal block (TB2) .........................................................53

Figure- 32 Zero contact input circuit (when open collector is used) ..................................................53

Figure- 33 Sample gas inlet ..............................................................................................................54

Figure- 34 Zero gas inlet ..................................................................................................................54

Figure- 35 Ozone exhaust (enclosure-mount)....................................................................................54

Figure- 36 Zero gas exhaust (external) .............................................................................................55

Figure- 37 Sample gas inlet (water trap) ...........................................................................................55

Figure- 38 Sample gas flow rate adjustment .....................................................................................57

Figure- 39 Zero gas flow rate adjustment..........................................................................................57

Figure- 40 Water within the water trap .............................................................................................60

Figure- 41 How to replace the lamp unit...........................................................................................63

Figure- 42 How to adjust the sensor .................................................................................................64

Figure- 43 How to replace the fuses .................................................................................................64

Figure- 44 How to replace the 3-way solenoid valve (for High Concentration Ozone Analyzer)........65

Figure- 45 Solenoid valve assembly (for High Concentration Ozone Analyzer) ................................65

Figure- 46 How to replace the 3-way solenoid valve (for Off-gas Ozone Analyzer) ..........................66

Figure- 47 Solenoid valve assembly (for Off-gas Ozone Analyzer) ...................................................67

Figure- 48 Solenoid valve assembly (for Off-gas Ozone Analyzer) ...................................................67

Figure- 49 Pump assembly ...............................................................................................................67

Figure- 50 How to replace the Ozone scrubber (for High Concentration Ozone Analyzer) ................68

Figure- 51 How to replace the Ozone destruct (for Off-gas Ozone Analyzer) ....................................69

Figure- 52 How to replace the filter element.....................................................................................69

Figure- 53 How to replace the zero gas filter (for High Concentration Ozone Analyzer) ...................70

Figure- 54 How to replace the zero gas filter (for Off-gas Ozone Analyzer)......................................70

Figure- 55 How to replace the sample gas filter................................................................................70

Figure- 56 How to replace the flowmeter (for High Concentration Ozone Analyzer).........................71

Figure- 57 Flowmeter bracket assembly............................................................................................71

Figure- 58 How to replace the flowmeter (for Off-gas Ozone Analyzer) ...........................................72

Figure- 59 Flowmeter assembly........................................................................................................72

Figure- 60 How to replace the membrane drier .................................................................................72

Figure- 61 How to replace the enclosure-mount Ozone destruct........................................................73

Figure- 62 Outline drawing of Type S High Concentration Ozone Analyzer......................................84

Figure- 63 Outline drawing of Type R High Concentration Ozone Analyzer .....................................85

Figure- 64 Outline drawing of Type S Off-gas Ozone Analyzer ........................................................86

Figure- 65 Flow diagram of High Concentration Ozone Analyzer (Type S) .......................................87

Figure- 66 Flow diagram of High Concentration Ozone Analyzer (Type R).......................................88

Figure- 67 Flow diagram of Off-gas Ozone Analyzer (Type S)..........................................................89

Figure- 68 Circuit diagram ...............................................................................................................90

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 12 -

Table

Table- 1 Setting mode of sub display ................................................................................................25

Table- 2 Operation in the ALTP mode ...............................................................................................25

Table- 3 Default mode setting table ..................................................................................................36

Table- 4 Periodic replacement parts list ............................................................................................61

Table- 5 Self-diagnostic error operation............................................................................................74

Table- 6 Errors and remedies ............................................................................................................77

Table- 7 Modes and input/output signal operation.............................................................................81

Table- 8 5 minutes from power ON: State where the value of sensor 1 is 500 or lower

(Warm-up operation time: Less than 5 minutes)................................................................81

Table- 9 5 minutes from power ON: State where the value of sensor 1 is 500 or higher

(Warm-up operation time: Less than 5 minutes)................................................................81

Table- 10 State after the warm-up operation is completed

(Warm-up operation time: 5 minutes or longer) ................................................................82

Table- 11 Lamp control operation at the time of recovery from error 3 or lamp control voltage error 82

Table- 12 Pressure loss in each pipe diameter and pipe length ..........................................................83

Reference material

Reference material (1): Relation between modes and input/output signals......................................81

Reference material (2): Operation during 5 minutes after the power is turned on ...........................81

Reference material (3): Relation between pipe diameter and pipe length ........................................83

Reference material (4): Description of Pollution Degree 2 .............................................................83

Reference material (5): How to fasten the coupling........................................................................83

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 13 -

1. General description

These ME800-series ozone analyzers using UV absorption method are installation-type ozone

analyzers that enable measurement of ozone concentrations during the ozone process. They are

classified into two types: one for measuring the ozone generated and the other for measuring the

ozone discharged. Both of them are all-in-one measuring analyzers integrating major components

(some parts are mounted externally). Ozone concentrations can be measured just by installing the

analyzer vertically and performing electrical wiring and piping.

In addition, we adopt sequential zero calibration function as standard equipment to enable

long-term stable measurement, and the enclosure is composed by sealed structure that consider

the environmental resistance. Therefore, this enables outdoor use.

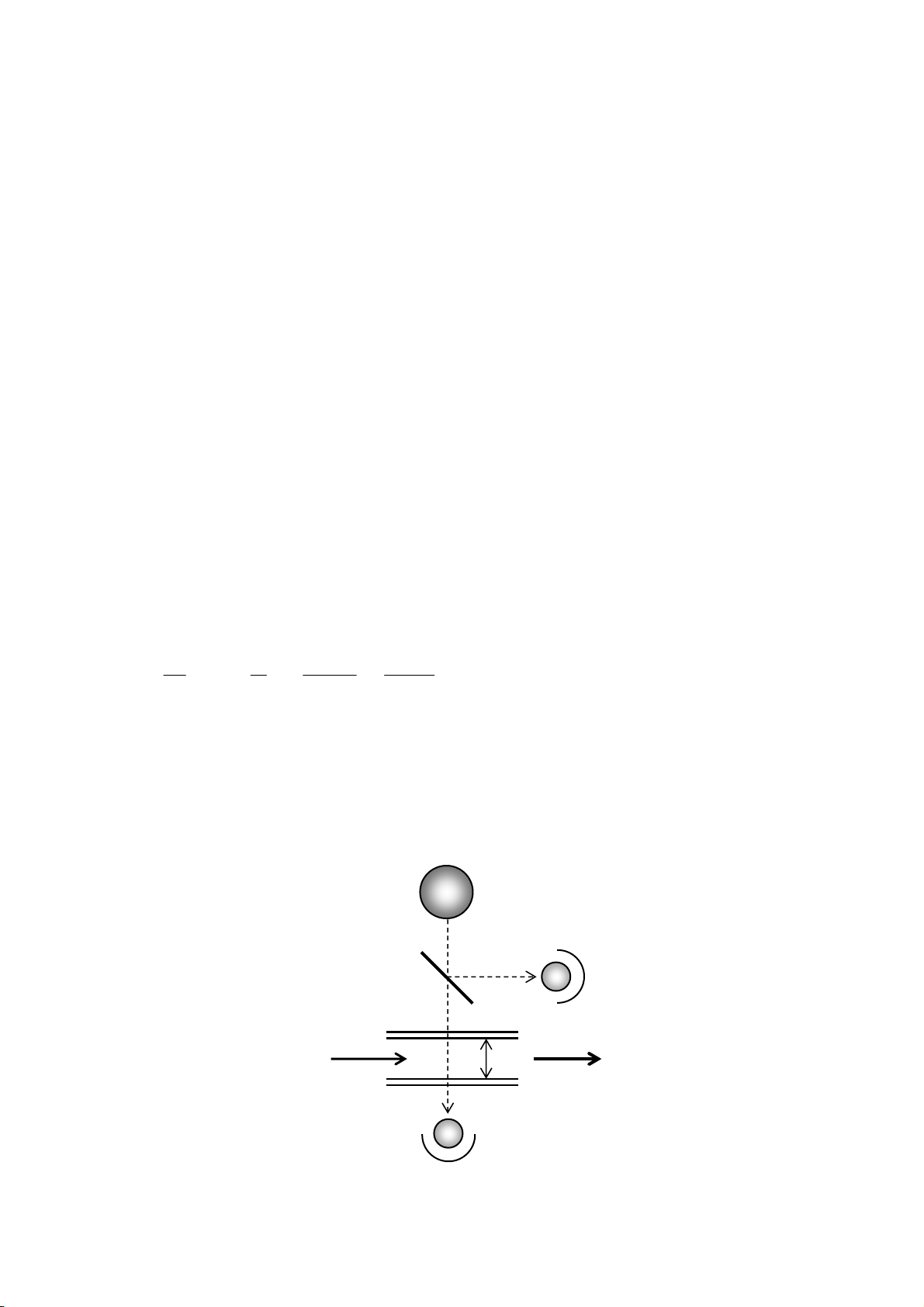

2. Measuring principle

This Analyzer is an UV absorption type ozone analyzer, which will detect and measure quantity

of UV ray absorbed by ozone in the sample gas introduced into the detector.

A low-pressure mercury lamp (emission wavelength 253.7 nm) is used for its light source and the

quantity of light absorbed by ozone existing within the optical path 'T' obeys the Lambert-Beer's

Law, so the concentration of ozone can be measured as follows. In addition, since the

measurement is affected by temperature and pressure, the measured values need to be corrected

under each situation using the following compensation formula.

C = A

αT× log

Io

Ix × 273 + t

273 × Po

P + Po

where: C : Concentration of ozone

α: Absorption coefficient of ozone

T : Optical path length (Cell gap)

Io : Incident UV light intensity

Ix : Transmitted UV light intensity

A : Constant

t : Gas temperature

Po : Atmospheric pressure

P : Gas pressure

Figure- 1 Logic Diagram

Ozone

Sensor 2

Sensor 1

T

Low-pressure

mercury lamp

IN

Ozone

OUT

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 14 -

3. Specifications

(1) High Concentration Ozone Analyzer

Model: ME810 (Type S, Type R)

Measuring principle: UV absorption method

Detection target: Generated ozone gas

Measuring Ranges: Select from the following ranges

0–15.0, 0–20.0 * unit: wt% (O2)

0–10.0, 0–20.0, 0–40.0 * unit: g/m3(N)

0–50.0, 0–100, 0–200

0–300

Measurement cycle: Continuous measurement

Sampling method: Pumped utilizing the supply pressure

Materials in contact

with gas:

SUS316, SUS304, PTFE, PCTFE, Quartz Glass, Pyrex glass,

Alumina, Fluorine-series resin, FFKM, etc.

(Zero gas line) SCS13A, Brass, Carbon steel, Zinc alloy, Nylon, PVA, FEP, PE,

NBR, HNBR, Glass fiber, PTFE, SUS304, etc.

* Ozone scrubber: Decomposing catalyst, FKM, Felt (Type S only)

Note: If the sample gas contains substances except ozone, the portions inside of the analyzer that

are exposed to gas may be eroded, damaged, or clouded. Please note that failures or

non-measurable state resulting from such damage are not included in the warranty even

during warranty period.

Sample Flow Rate: 0.5–1.0 L/min (0.5 L/min recommended)

Normal Operating

Pressure:

0.01–0.10 MPa(G) (internal supply pressure of piping of the analyzer)

(pressure when the adjustment valve is fully open)

Maximum Pressure: 0.2068 MPa(G) or less

(supply pressure of the analyzer: 30 psig or less)

Outlet Pressure: Atmospheric pressure

Span drift: Within ±1% FS/month

Zero drift: Within ±1% FS/month (Refer to the Note below.)

Note: Need to perform Zero calibration by integrated timer once

every 24 hours.

Use a gas not contained ozone, not be polluted (dry) as a zero

calibration gas.

Linearity: Within ±1% FS

Repeatability: 0.2% FS or less

Zero Adjustment: Zero calibration by integrated timer is performed once every 24 hours

(in automatic operation).

* Based on zero/interval setting

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 15 -

Display: Main display: Red/Green 7 Segment LED (4 digits)

Sub display: Red 7 Segment LED (4 digits)

MODE: 5 LED Lamps

MES (MEASUREMENT): Stays on during measurement / blinks

during zero calibration

ALM (ALARM1, 2): Blinks at occurrence of an alarm

ERR (ERROR): Blinks at occurrence of analyzer error

CHK: Turns on when check is being conducted / blinks during setting

mode

TES: Turns on when test is being conducted

UNIT: LED Lamp

Span Adjustment: Performed by digital setting (0.000-2.000)

Analyzer Output: Relay contact output: dry contact

• Measurement signal: output only when the measurement is

progressing normally

• Concentration alarm: any single-level alarm setting is available;

2 systems

• Analyzer error signal: output when an abnormal condition occurs

Contact rating: 250 V AC 5 A (resistance load)

250 V AC 1.5 A (induction load)

30 V DC 5 A (resistance load)

30 V DC 1.5 A (induction load)

MEASUREMENT: Measurement signal (c contact)

ALARM 1: Concentration alarm 1 signal (c contact)

ALARM 2: Concentration alarm 2 signal (c contact)

ERROR: Analyzer error signal (a contact)

Analyzer Input: Zero calibration input signal (insulation output)

Analog Output: 0–1 V DC, 0–10 V DC

1–5 V DC, 4–20 mA DC

One of the above is to be selected.

* The load resistance connectable externally is 10 kor more for

voltage output, and 550 or less for current output.

Self-diagnosis

Function:

Light source abnormalities, cell contamination, sensor abnormalities,

internal circuit abnormalities, and measurement accuracy analysis

results are detected and displayed.

Test Mode: Analog output, alarm contact, solenoid valve operation, and contact

input can be tested.

Power Supply: 100–240 V AC ±10%, 50/60 Hz

Power Consumption: 55 VA or less

Dimensions: 321 (W) × 428 (H) × 202 (D) [mm]

* Protruding parts are not included in these dimensions.

Equivalent to NEMA4x (IP65)

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 16 -

Mass: Approximately 15 kg

Pipe Port:

(sample inlet (S type,

R type), zero gas inlet

(R type))

Rc 1/4'' socket

* In the case of connecting the sample gas that can be measured without

problems and has undergone pretreatment (having adjusted the flow

rate and having removed dust and so on), without using the accessory

filter and valve assembly or zero gas and valve assembly (R type).

Pipe ports diameter:

(sample gas inlet)

Select one from the following pipe ports diameter

Ø1/4 inch, Ø3/8 inch, Ø6 mm, Ø10 mm (sample gas inlet)

* In the case of using the accessory filter and valve assembly or zero

gas and valve assembly (R type).

Wire Ports: Power supply/control cable port: Ø9 mm–Ø22 mm

Signal cable port: Ø4 mm–Ø12 mm

Ambient temperature: 0°C–45°C

Relative humidity: 90 % RH or less within the case (no condensation)

Temperature

compensation:

Measurement range: 0°C–50°C

Temperature compensation: 0°C (Switchable to 20°C compensation)

Others: Warm-up time is settable for duration of 0 to 99 minutes

(default:10minute)

♦Option

Pressure compensation: Compensation range: 80–130 kPa (abs) (optional)

Pressure sensor (Measurement range: 0.35 MPa (abs))

(2) Off-gas Ozone Analyzer

Model: ME820 Type S

Measuring principle: UV absorption method

Detection target: Exhaust ozone gas

Measuring ranges: Select from the following ranges

0–10.0, 0–20.0, 0–40.0 *unit: g/m3(N)

0–50.0, 0–100

0–1000, 2000 *unit: ppm

Measurement cycle: Continuous measurement

Sampling method: Suction by internal pump

Materials in contact

with gas:

SUS316, SUS304, PFA, PTFE, PCTFE, PVDF, PVC, Quartz glass,

Alumina, Fluorine-series resin, FKM, Glass fiber, Sapphire, etc.

(Zero gas line) PVA, FEP, PE, NBR, PBT, POM, HNBR, FKM, SUS304, PVDF,

EPDM, Phenol resin, Felt, Pyrex glass, Glass fiber, Brass, Carbon

steel, Zinc alloy, Nylon, TYGON®, etc.

* Ozone destruct: Decomposing catalyst, FKM, Felt

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 17 -

Note: If the sample gas contains substances except ozone, the portions inside of the analyzer that

are exposed to gas may be eroded, damaged, or clouded. Please note that failures or

non-measurable state resulting from such damage are not included in the warranty even

during warranty period.

Sample Flow Rate: 1.0–2.0 L/min (1.0 L/min recommended)

Maximum Pressure: Within ±10k Pa(G) (0.10 M Pa(G) or less without a sampling pump)

Outlet Pressure: Atmospheric pressure

Span drift: Within ±1% FS/month

Zero drift: Within ±1% FS/month (Refer to the Note below)

Note: Need to perform Zero calibration by integrated timer,

performed once every 24 hours. Use a gas not contained ozone,

not be polluted (dry) as a zero calibration gas.

Linearity: Within ±1% FS

Repeatability: 0.2% FS or less

Zero Adjustment: Zero calibration by integrated timer performed once every 24 hours

(in auto operation)

* Based on zero/interval setting

Display: Main display: Red/Green 7 Segment LED (4 digits)

Sub display: Red 7 Segment LED (4 digits)

MODE: 5 LED Lamps

MES (MEASUREMENT): Stays on during measurement / blinks

during zero calibration

ALM (ALARM1, 2): Blinks at occurrence of an alarm

ERR (ERROR): Blinks at occurrence of analyzer error

CHK: Turns on when check is being conducted / blinks during setting

mode

TES: Turns on when test is being conducted

UNIT: LED Lamp

Span Adjustment: Performed by digital setting (0.000–2.000)

Analyzer Output: Relay contact output: dry contact

• Measurement signal: output only when the measurement is

progressing normally

• Concentration alarm: any single-level alarm setting is available;

2 systems

• Analyzer error signal: output when an abnormal condition occurs

Contact rating: 250 V AC 5 A (resistance load)

250 V AC 1.5 A (induction load)

30 V DC 5 A (resistance load)

30 V DC 1.5 A (induction load)

MEASUREMENT: Measurement signal (c contact)

ALARM 1: Concentration alarm 1 signal (c contact)

ALARM 2: Concentration alarm 2 signal (c contact)

ERROR: Analyzer error signal (a contact)

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 18 -

Analyzer Input: Zero calibration input signal (insulation output)

Analog Output: 0–1 V DC, 0–10 V DC

1–5 V DC, 4–20 mA DC

Select one from the above.

* The load resistance connectable externally is 10 kor more for

voltage output, and 550 or less for current output.

Self-diagnosis

Function:

Light source abnormalities, cell contamination, sensor abnormalities,

internal circuit abnormalities, and measurement accuracy analysis

results are detected and displayed.

Test Mode: Analog output, alarm contact, solenoid valve operation, and contact

input can be tested.

Power Supply: 100–240 V AC ±10%, 50/60 Hz

Power Consumption: 55 VA or less

Dimensions: 321 (W) × 428 (H) × 202 (D) [mm]

* Protruding parts are not included in these dimensions.

Equivalent to NEMA4x (IP65)

Mass: Approximately 15 kg

Pipe Ports:

(sample inlet, sample

exhaust outlet)

Rc 1/4'' socket

* Sample inlet: In the case of connecting the sample gas that can be

measured without problems and has removed moisture, without

using accessory filter and valve assembly.

Pipe Ports diameter:

(sample gas inlet)

Select one from the following

Ø3/8 inch (Ø10 mm), switchable between Ø1/4 inch and Ø3/8 inch,

switchable between Ø5/16 inch and Ø3/8 inch

* In the case of using accessory water trap

Wire Ports: Power supply/control cable port: Ø9 mm–Ø22 mm

Signal cable port: Ø4 mm–Ø12 mm

Ambient temperature: 0°C–45°C

Relative humidity: 90 % RH or less within the case (no condensation)

Temperature

compensation:

Measurement range: 0°C–50°C

Temperature compensation: 0°C (Switchable to 20°C compensation)

Others: Warm-up time is settable for duration of 0 to 99 minutes

(default: 10minutes)

♦Option

Pressure compensation: Compensation range: 80–130 kPa (abs) (optional)

Pressure sensor (Measurement range: 0.35 MPa (abs))

EOP-D73-001-7-002-05E

E.J. OZONE PRODUCTS - 19 -

Protective cover

: Optional parts

4. Names of each part and description of functions

(1) High Concentration Ozone Analyzer Type S

Figure- 2 Names of each part of ME810 Type S

[21] [22]

[20]

[1]

[3]

[42]

[49]

[5]

[4]

[2]

[6]

[7]

[3]

[33]

[32]

[34]

[42]

[41]

[8]

[6]

[2]

[9]

[C]

[7] [51] [15]

[16]

[10]

[14]

[13]

[24][11][19][17][18][12][23]

[41][27]

[50]

[47]

[26]

[25]

[B]

[A]

Table of contents

Popular Measuring Instrument manuals by other brands

Mirion Technologies

Mirion Technologies DMC 3000 user guide

Konica Minolta

Konica Minolta AeroDR System Operation manual

BURG WATCHER

BURG WATCHER ProfiScale CROSS operating instructions

Precision Digital Corporation

Precision Digital Corporation PROVU Series manual

PFlow Industries

PFlow Industries P117 instruction manual

vse

vse VSI 0.04 operating manual